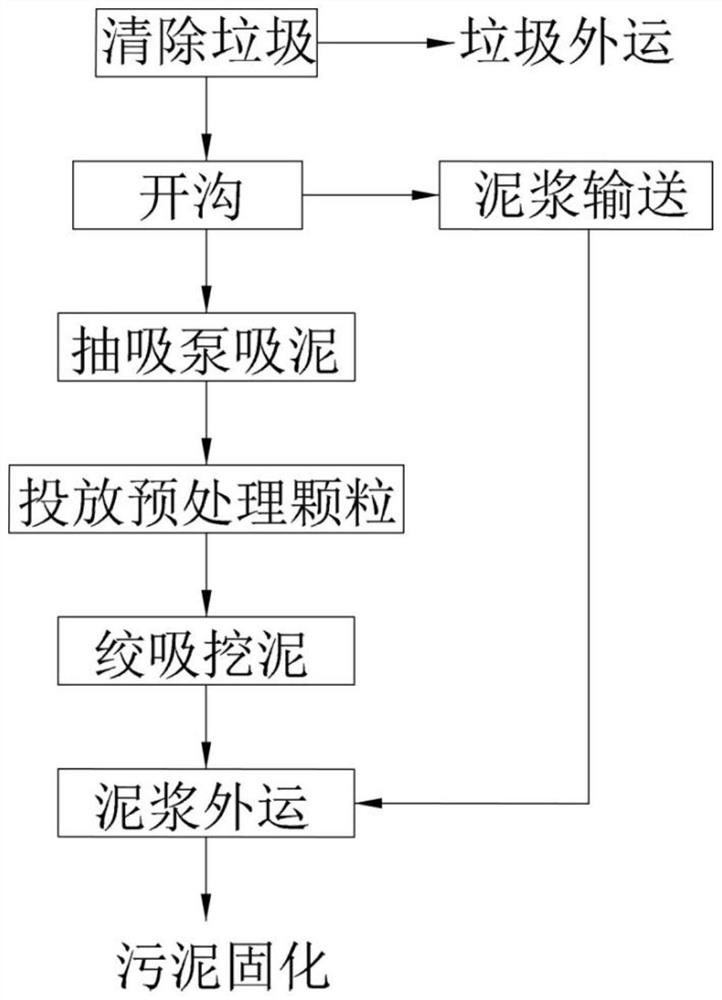

Environment-friendly dredging and desilting method

An environmental protection dredging and silting technology, which is applied in water conservancy projects, sea area engineering, river regulation, etc., can solve the problems of pollution migration and environmental protection dredging projects can not achieve the expected results, and achieve the effect of reducing the spread of silt and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment one pretreatment particle 1

[0037] Preparation of protective layer material

[0038] Weigh chitosan powder and add it to 2wt% acetic acid solution, heat to 65°C and stir until completely dissolved to obtain a chitosan solution with a mass concentration of 20 mg / ml, then add ammonium sulfate solution dropwise, wherein the mass of ammonium sulfate is shell 1% of the mass of polysaccharide, stir and mix evenly, add hydroxypropyl methylcellulose with 3 times the mass of chitosan, stir and mix evenly, put it in a microwave oven at 70W power for 1min, and then react at 210W power for 2h After the reaction is completed, the reactant is washed twice with absolute ethanol, soaked for 3 hours, filtered, dried at 60° C., and pulverized to obtain chitosan-grafted hydroxypropyl methylcellulose.

[0039] Preparation of modified chitosan

[0040] Quaternization: weigh chitosan powder and add it to 2wt% acetic acid solution, heat up to 80°C and continu...

Embodiment 2

[0047] The preparation of embodiment two pretreatment granules 2

[0048] The preparation of the protective layer material is the same as in Example 1.

[0049] Preparation of modified chitosan

[0050] Quaternization: weigh chitosan powder and add it to 2wt% acetic acid solution, heat up to 80°C and continue to stir until chitosan is completely dissolved to obtain a chitosan solution with a mass concentration of 25 mg / ml, then weigh 2,3-cyclo Oxypropyltrimethylammonium chloride was added to deionized water and stirred to dissolve, then added to the chitosan solution, and reacted at a constant temperature at 80°C for 10 hours. After the reaction was completed, it was precipitated with absolute ethanol to obtain a white flocculent precipitate, which was vacuum filtered and used After washing with acetone, dry at 60°C to obtain quaternized chitosan;

[0051] Grafting modification: Stir and dissolve the prepared quaternized chitosan in 2% acetic acid solution, stir until comple...

Embodiment 3

[0057] The preparation of embodiment three pretreatment granules 3

[0058] The preparation of the protective layer material is the same as in Example 1.

[0059] Preparation of modified chitosan

[0060] Quaternization: weigh chitosan powder and add it to 2wt% acetic acid solution, heat up to 80°C and continue to stir until chitosan is completely dissolved to obtain a chitosan solution with a mass concentration of 35 mg / ml, then weigh 2,3-cyclo Oxypropyltrimethylammonium chloride was added to deionized water and stirred to dissolve, then added to the chitosan solution, and reacted at a constant temperature at 80°C for 10 hours. After the reaction was completed, it was precipitated with absolute ethanol to obtain a white flocculent precipitate, which was vacuum filtered and used After washing with acetone, dry at 60°C to obtain quaternized chitosan;

[0061] Grafting modification: Stir and dissolve the prepared quaternized chitosan in 2% acetic acid solution, stir until comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com