Gel polymer battery and preparation method thereof

A gel polymer, polymer technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of battery safety hazards, no electrolyte and other problems, so as to help transmission and improve battery performance , the effect of inhibiting the growth of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

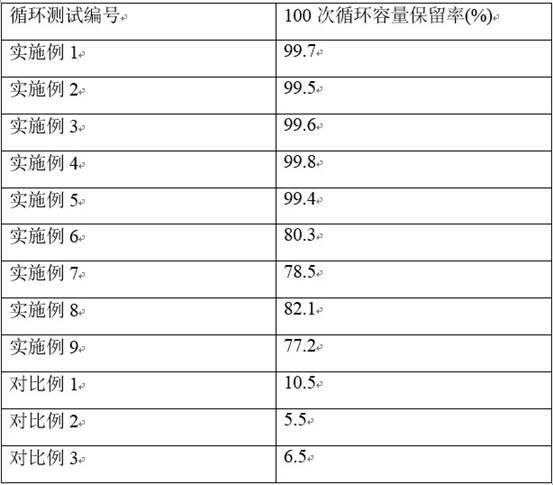

Examples

preparation example Construction

[0039] In a second aspect, the present invention provides a method for preparing a gel polymer battery as described above, comprising the following steps:

[0040] (1) Preparation of ether electrolyte containing ether organic solvent, lithium salt, polymer monomer and initiator; preparation of carbonate electrolyte containing carbonate organic solvent, lithium salt, polymer monomer and initiator ;

[0041] (2) Prepare a semi-finished battery from the negative electrode, the positive electrode, and the ether electrolyte and carbonate electrolyte in step (1);

[0042] (3) Put the semi-finished battery obtained in step (2) in an oven to obtain a gel polymer battery.

[0043] In one embodiment, in step (1), the number of moles of lithium salt per unit volume is the same as the number of moles of organic solvent; the amount of polymer monomer added accounts for 1-20wt of the ether electrolyte or carbonate electrolyte %, the amount of the initiator added accounts for 0.5-10wt% of ...

Embodiment 1

[0054] (1) Preparation of ether electrolyte:

[0055] Add the lithium salt LiFSI to the ether organic solvent tetraethylene glycol dimethyl ether (TEGDME), so that the molar ratio of the lithium salt to the organic solvent is 1:1, and then add the polymer monomer ethoxylated trimethylol Ethyl propane triacrylate (ETPTA) and ethylene glycol diacrylate (PEGDA), so that its mass proportion is 5%, then add initiator azobisisobutyronitrile (AIBN), so that its mass proportion is 0.5wt %, magnetically stirred at room temperature for 0.5 h to obtain an ether electrolyte.

[0056] (2) Carbonate electrolyte preparation

[0057] Add lithium salt LiFSI to carbonate organic solvent diethyl carbonate (DEC), so that the molar ratio of lithium salt to organic solvent is 1:1, and then add polymer monomer ethoxylated trimethylolpropane Triacrylate (ETPTA) and ethylene glycol diacrylate (PEGDA), make its mass proportion be 5%, then add initiator azobisisobutyronitrile (AIBN), make its mass pro...

Embodiment 2

[0060] The difference from Example 1 is that in step (3), the ether electrolyte in (1) is first dropped on the surface of the lithium sheet, a diaphragm is placed on it, and the carbonate electrolyte is added dropwise on the diaphragm, and then The ternary positive electrode is placed on the carbonate electrolyte to form a button battery; in the obtained battery, the thickness of the ether gel polymer electrolyte layer is 10 μm, and the thickness of the carbonate gel polymer electrolyte layer is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com