Permanent magnet synchronous motor discrete domain current loop control method introducing advanced beat current

A technology of permanent magnet synchronous motor and control method, which is applied in motor generator control, electronically commutated motor control, motor, etc., and can solve problems such as unequal inductance of AC and direct axes, system instability, and disturbance of control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In the following, the discrete-domain current loop control method of the permanent magnet synchronous motor with lead current introduced in the present invention will be described in detail with reference to the drawings and embodiments.

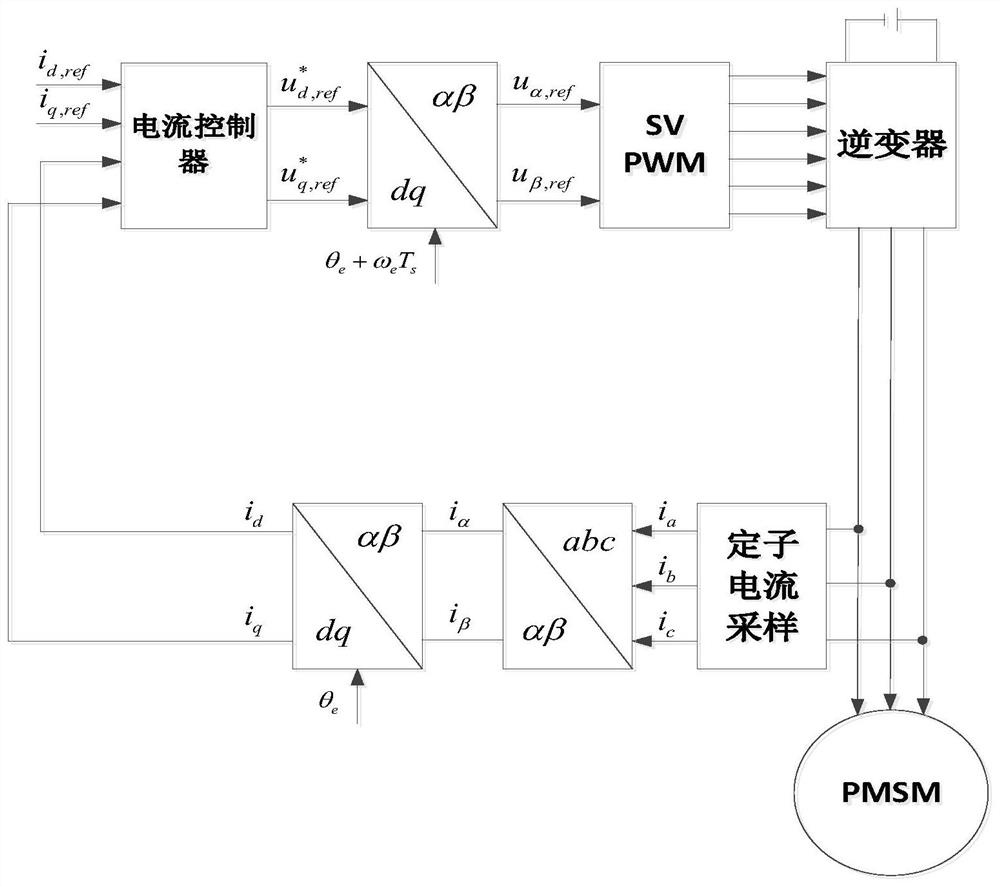

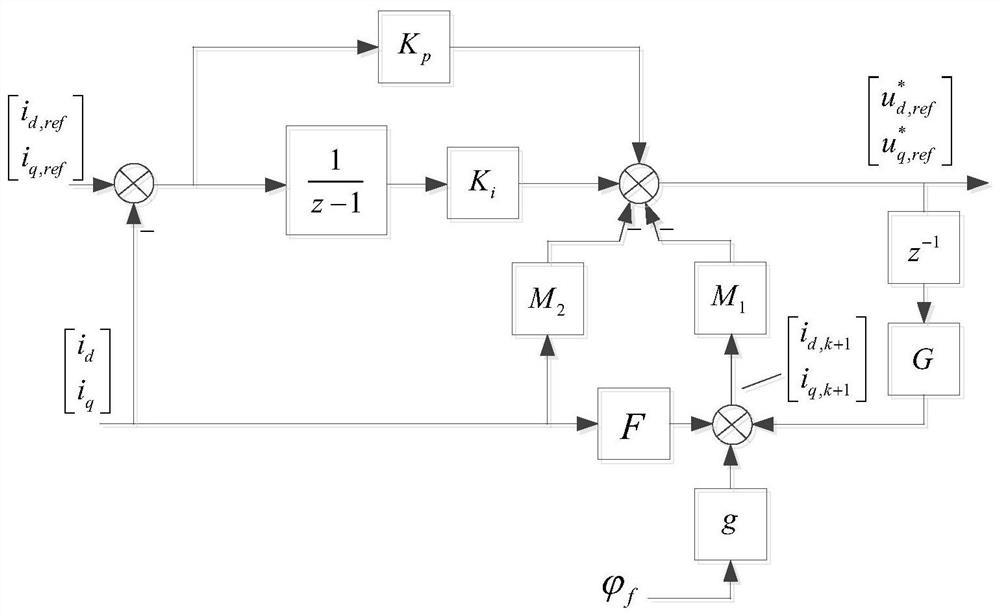

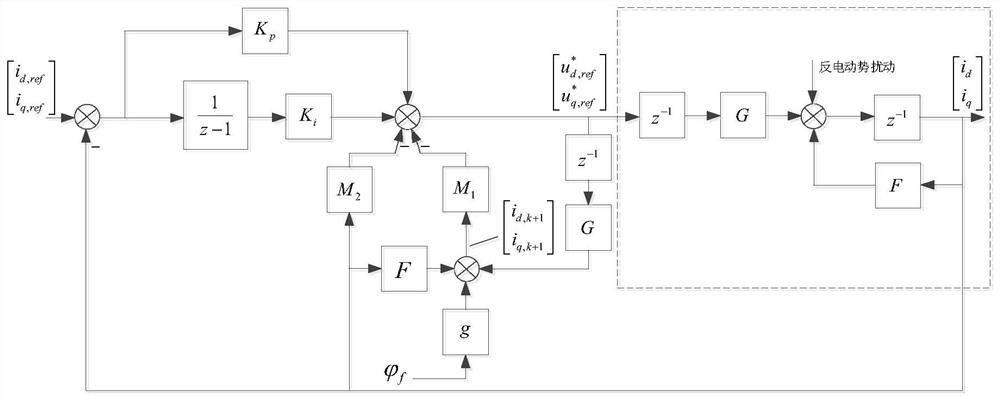

[0069] figure 1 The control block diagram of the discrete domain current loop control system of the permanent magnet synchronous motor that introduces the lead beat current for the present invention, figure 2 It is a structural block diagram of a permanent magnet synchronous motor current controller in the present invention, image 3 It is an equivalent structural block diagram of the permanent magnet synchronous motor current loop control system in the rotating dq coordinate system in the present invention. Depend on figure 1 , figure 2 and image 3 Visible, the present invention comprises the following steps:

[0070] Step 1, collect the rotor electrical angular velocity ω of the permanent magnet synchronous motor e and roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com