ZrOx for plating optical film and preparation method of ZrOx

An optical film and block technology, applied in the direction of zirconia, coatings, etc., can solve the problems of explosion, high technical requirements for reaction equipment and operation control, easy combustion and other problems, and achieve stable chemical properties, stability and consistency Good, stable evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

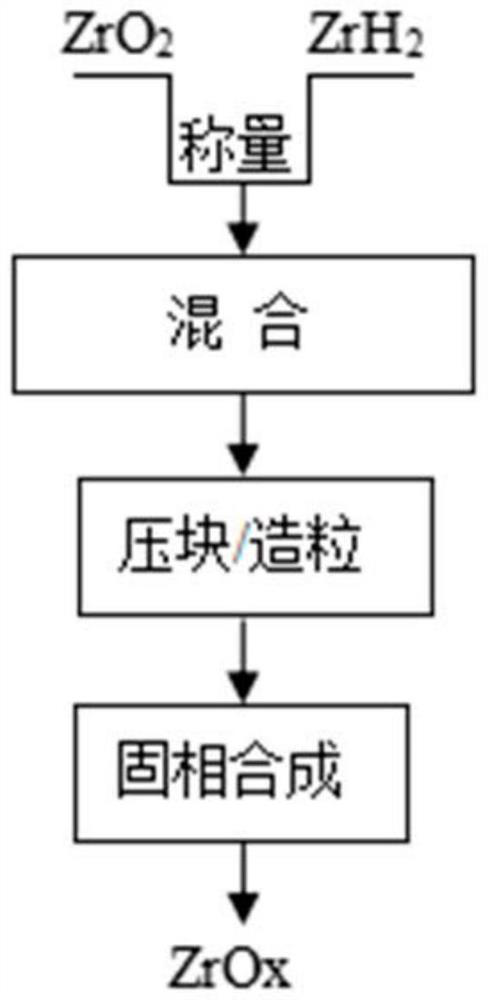

[0035] use as figure 1 The process shown in the preparation of ZrO x : ZrH 2 Powder and ZrO 2 The powder is weighed according to the ratio of 2:5 by weight, and the mixing machine is used for mechanical mixing for 6 hours, and the mixed powder is mixed at 300 N / cm 2 The block is pressed under a certain pressure, and then the block material is crushed and sieved to make particles with a particle size of 1-3mm. -1 The solid-phase synthesis reaction was carried out under the condition of Pa for 6 hours, and cooled to room temperature under vacuum.

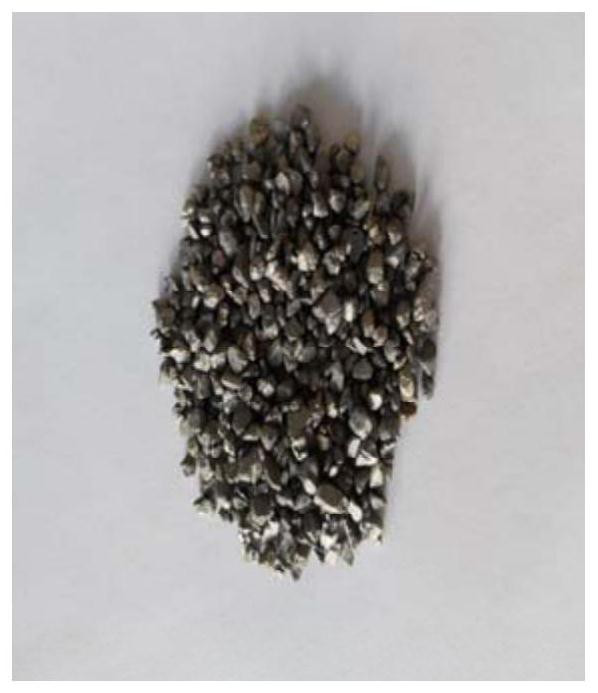

[0036] The material prepared by this method is a dark gray material (such as figure 2 shown), the density of the material tested by the drainage method is 5.0g / cm 3 , XRD analysis showed that the material was composed of a new compound Zr 3 O and some ZrO 2 composition. When in use, the ZrOx material is fully pre-melted first, and pre-melted in a water-cooled oxygen-free copper crucible. The pre-melting temperature is about 230...

Embodiment 2

[0038] use as figure 1 The process shown in the preparation of ZrO x : ZrH 2 Powder and ZrO 2 The powder is weighed according to the ratio of 2:3 by weight, and the ball mill is used for mechanical mixing for 4 hours, and the mixed powder is mixed by a hydraulic machine at 600N / cm 2 The block is pressed under a certain pressure, and the block material is crushed and sieved to make particles with a particle size of 1-3mm. -2 The solid-phase synthesis reaction was carried out under the condition of Pa for 8 hours, and cooled to room temperature under vacuum.

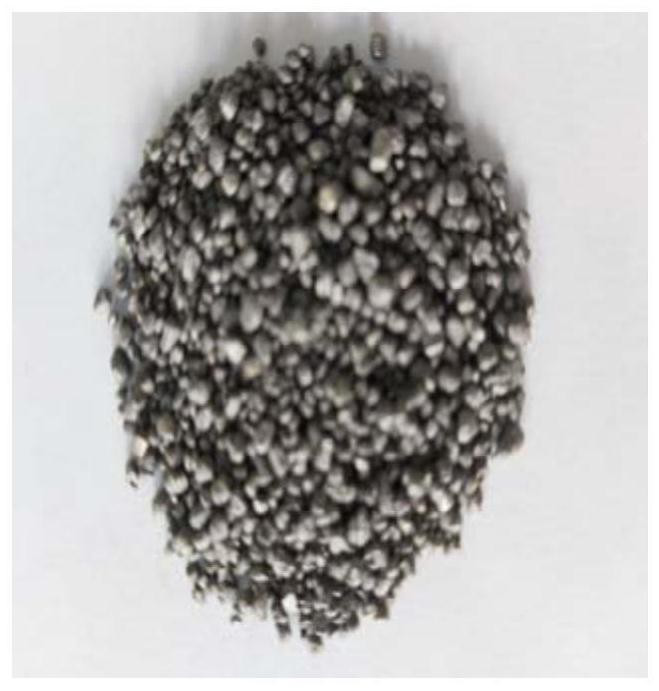

[0039] The material prepared by this method is a dark gray material (such as image 3 shown), the density of the material tested by the drainage method is 5.2g / cm 3 , XRD analysis showed that the material was composed of a new compound Zr 3 O and some ZrO 2 composition (such as Figure 4 shown). When in use, the ZrOx material is fully pre-melted first, and pre-melted in a water-cooled oxygen-free copper crucible. ...

Embodiment 3

[0041] use as figure 1 The process shown in the preparation of ZrO x : ZrH 2 Powder and ZrO 2 The powder is weighed according to the ratio of 3:2 by weight, and the mixing machine is used for mechanical mixing for 8 hours, and the mixed powder is mixed by a hydraulic press at 500N / cm 2 briquetting under a certain pressure, and then the material is crushed and sieved to make particles with a particle size of 1-5mm. -3 The solid-phase synthesis reaction was carried out under the condition of Pa for 10 hours, and cooled to room temperature under vacuum.

[0042] The material prepared by this method is a dark gray material (such as Figure 6 shown), the density of the material tested by the drainage method is 5.4g / cm 3 , XRD analysis showed that the material was composed of a new compound Zr 3 O and some ZrO 2 composition. When in use, the ZrOx material is fully pre-melted first, and pre-melted in a water-cooled oxygen-free copper crucible. The pre-melting temperature is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com