Concentration treatment device and method for chemical nickel-plating rinsing wastewater

A technology of electroless nickel plating and treatment device, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., and can solve the problems of large floor space, high adsorbent cost, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

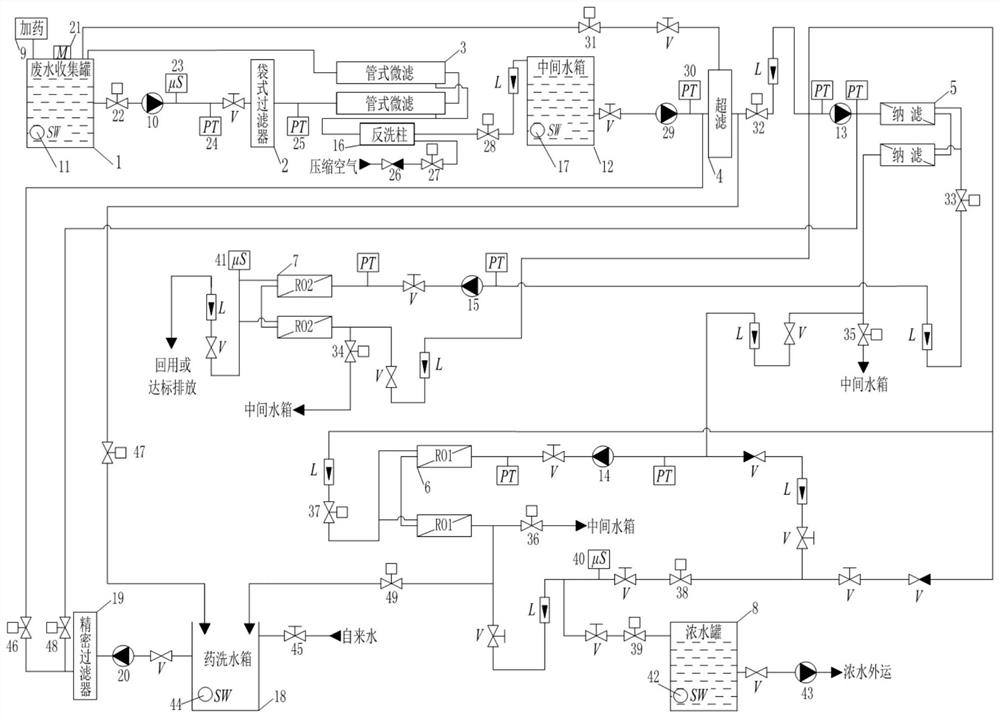

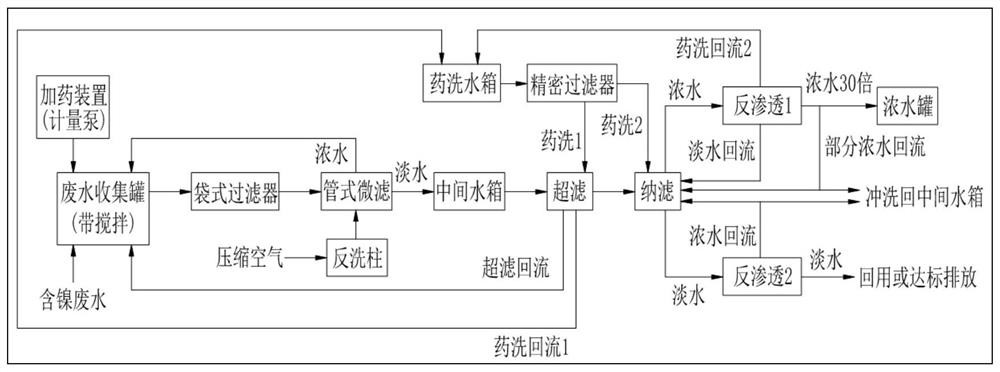

[0029] A concentration treatment device for electroless nickel-plating rinsing wastewater of the present invention comprises a wastewater collection tank, a raw water pump, a bag filter, a tubular microfiltration, an intermediate water tank, an ultrafiltration, a nanofiltration and a first reverse osmosis successively connected through pipelines The concentrated water of the tubular microfiltration and the concentrated water of the ultrafiltration are respectively connected to the waste water collection tank, the concentrated water side of the nanofiltration is connected to the first reverse osmosis membrane, and the fresh water side of the nanofiltration is connected to the second reverse osmosis membrane. Two reverse osmosis membranes, the fresh water side outlet pipe of the first reverse osmosis membrane is provided with a conductivity meter, the fresh water of the first reverse osmosis membrane is returned to the water inlet side of the nanofiltration, and the concentrated w...

Embodiment 2

[0053] The use method of the concentrated treatment device of electroless nickel plating rinsing waste water of the present invention comprises the following steps,

[0054] 1) Add HMC-M2 nickel removal agent, PAC coagulant and neutral PAM flocculant to waste water collection tank 1, so that the suspended matter, organic matter, colloid, etc. Settling in the waste water collection tank and being effectively removed in the subsequent bag filter 2;

[0055] First of all, in order to capture the metal nickel in the complex state, it is necessary to add HMC-M2 nickel removal agent to the wastewater, and use its high-efficiency and selective effect to directly remove the complex nickel. Secondly, electroless nickel plating rinsing wastewater inevitably contains organic matter, so it is necessary to add PAC coagulant polyaluminum chloride to destroy and degrade organic matter. There are other impurities in the raw water, such as suspended solids and colloids. These impurities often...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com