Magnesium-sulfur battery, transition metal sulfide/sulfur composite positive electrode material and composite method

A composite cathode material, transition metal technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problem that the cycle performance of magnesium-sulfur batteries is difficult to obtain a large improvement, reduce the energy density of magnesium-sulfur batteries, and cannot suppress the shuttle effect, etc. problem, to achieve the effect of inhibiting the shuttle effect, increasing the cycle stability, high electronic conductivity and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

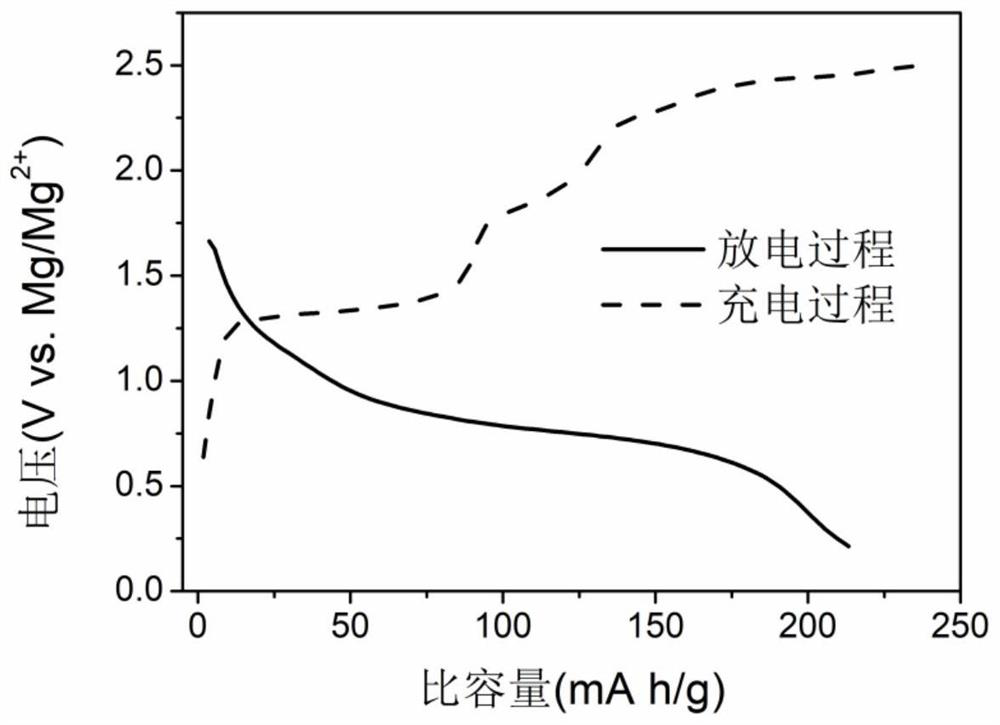

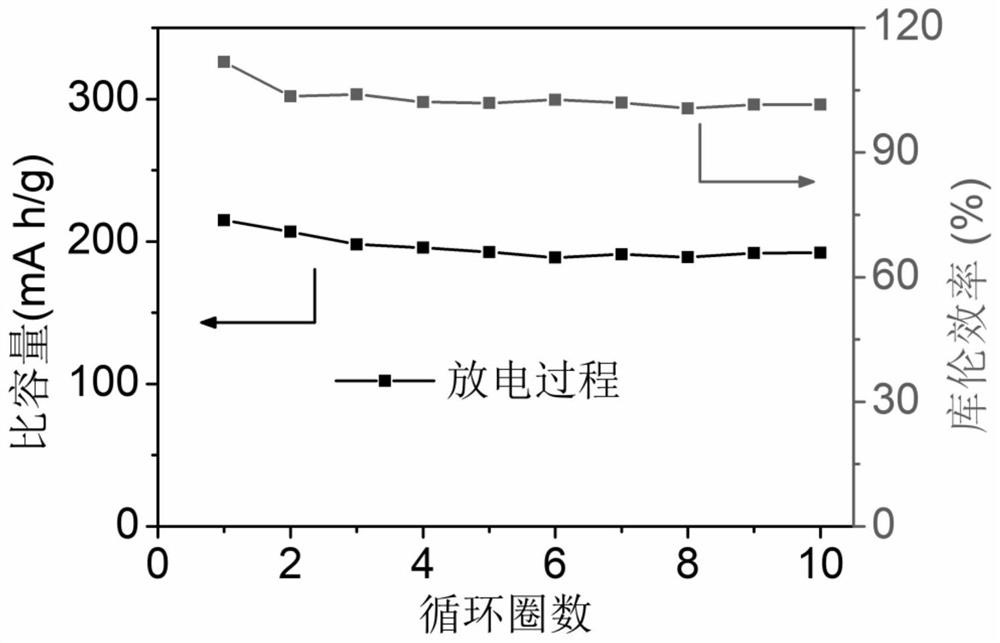

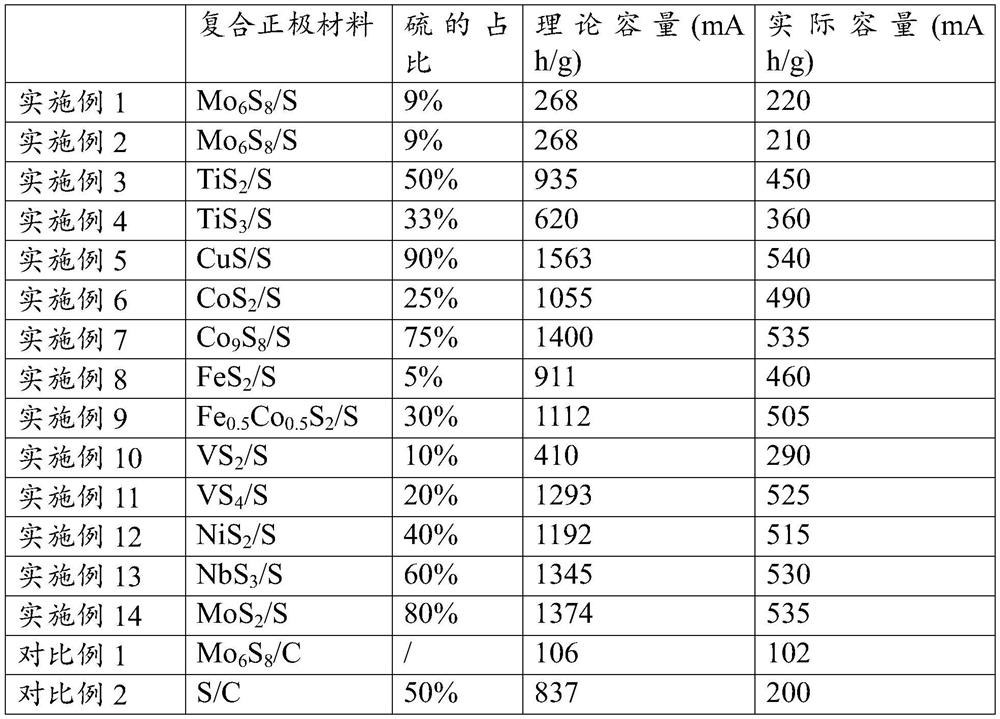

[0053] This embodiment provides a Mo 6 S 8 / S composite cathode material preparation and performance testing.

[0054] (1)Mo 6 S 8 Synthesis: Take molybdenum disulfide, copper sulfide, and molybdenum powder with a molar ratio of 3:2:3, ball mill for 0.5h, and then in 10 6 Press down into granules and put them into a sealed stainless steel tube; raise the temperature to 900 degrees Celsius at a rate of 2 degrees Celsius per minute in argon, keep it for 24 hours and then cool down naturally to obtain Cu 2 Mo 6 S 8 . Then it was placed in 6 molar HCl for 12 hours with oxygen to remove Cu. The product was washed with water and dried in a vacuum oven at 100 degrees Celsius for 12 hours to obtain Mo 6 S 8 .

[0055] (2)Mo 6 S 8 / S composite material preparation: weigh 1g Mo 6 S 8 , 0.1g of precipitated sulfur, 1g of graphene, 1g of Ketjen black, placed in a ball mill jar, sealed and ball milled for 1 hour to obtain Mo 6 S 8 / S Composite.

[0056] (3) Weigh Mo respec...

Embodiment 2

[0060] This embodiment provides a Mo 6 S 8 / S composite cathode material preparation and performance testing.

[0061] (1)Mo 6 S 8 Synthesis: Take molybdenum disulfide, copper sulfide, and molybdenum powder with a molar ratio of 3:2:3, ball mill for 0.5h, and then in 10 6 Press down into granules and put them into a sealed stainless steel tube; raise the temperature to 900 degrees Celsius at a rate of 2 degrees Celsius per minute in argon, keep it for 24 hours and then cool down naturally to obtain Cu 2 Mo 6 S 8 . Then it was placed in 6 molar HCl for 12 hours with oxygen to remove Cu. The product was washed with water and dried in a vacuum oven at 100°C for 12 hours to obtain Mo 6 S 8 .

[0062] (2)Mo 6 S 8 / S composite material preparation: weigh 1gMo 6 S 8 , 0.1g carbon nanotubes, 0.1g acetylene black, put in a ball mill jar, add 20mL water and 20mL ethanol, seal the ball mill for 1 hour; then dissolve 0.5g sodium thiosulfate in it, then slowly add 0.5 mole H ...

Embodiment 3

[0066] This embodiment provides a TiS 2 / S composite cathode material preparation and performance testing.

[0067] (1)TiS 2 / S composite material preparation: weigh 1g TiS 2 , 1g of precipitated sulfur, 0.7g of graphene, and 0.7g of Ketjen black were placed in a ball mill jar, sealed and ball milled for 24 hours to obtain TiS 2 / S Composite.

[0068] (2) Weigh TiS with a mass ratio of 7:1:1:1 2 / S composite material, Super-P carbon black, carbon nanotubes, polyacrylic acid, ground evenly, rolled into a film, and dried to obtain the positive electrode sheet. The content of the active substance is 2mg / cm 2 .

[0069] (3) In a glove box filled with argon, the positive electrode sheet, magnesium foil, and 0.03 mole of MgCl 2 -AlCl 3 -Mg(TFSI) 2 Dissolved in tetrahydrofuran electrolyte to assemble a soft pack battery. And the battery at 0.2-2.5Vvs.Mg / Mg 2+ Electrochemical tests were carried out in the range. The capacity test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com