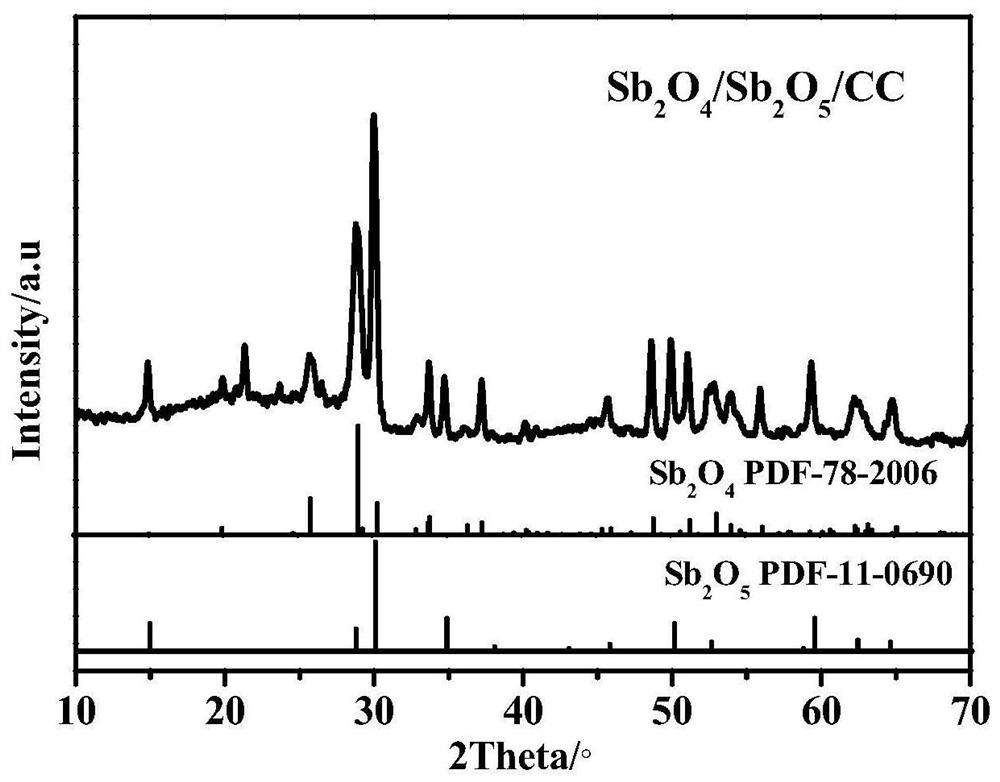

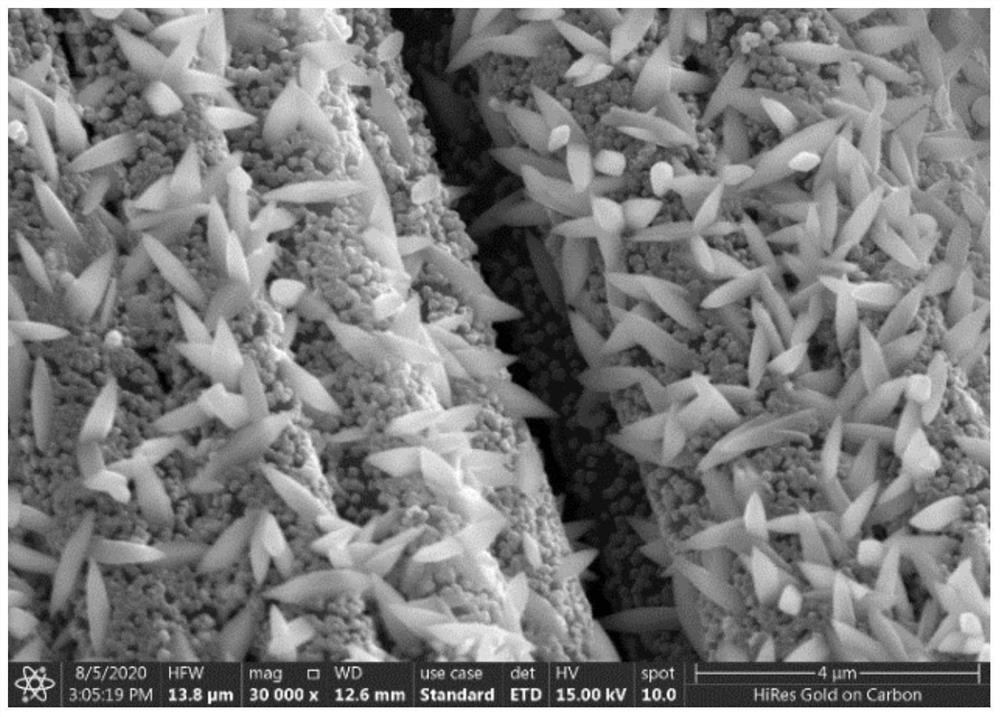

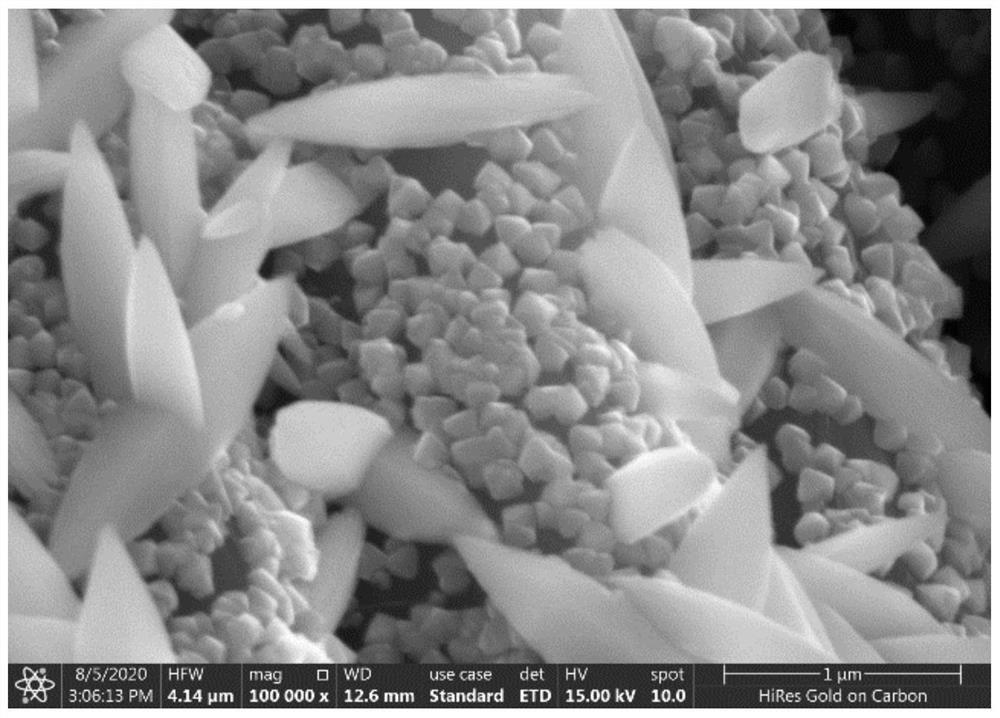

Carbon cloth loaded flower-shaped Sb2O4@polyhedral Sb2O5 composite self-supporting electrode material and preparation method thereof

A technology of self-supporting electrodes and polyhedrons, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., to achieve the effects of strong repeatability, simple preparation method, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Carbon cloth of the present invention supports flower-shaped Sb 2 o 4 @polyhedronSb 2 o 5 The preparation method of composite self-supporting electrode material, concrete steps comprise:

[0029] Step (1): Take 0.006 g of single-layer graphene oxide powder with a sheet diameter of 0.5-5 μm and a thickness of 0.8-1.2 nm, put it in 20 mL of deionized water, and ultrasonically vibrate to obtain solution A;

[0030] Step (2): Add 0.57g antimony trichloride to solution A obtained in step (1), and use 0.6mg / mL sodium hydroxide solution to adjust pH=12, continue stirring to form a reaction precursor, and use 20 ~25g / L ammonium dihydrogen phosphate is used as the electrolyte to anodize and activate the carbon cloth, the anodizing voltage is 5V, the anodizing time is 3~5min, and the activated carbon is placed in the reaction precursor and immersed for 30min;

[0031] Step (3): Transfer the carbon cloth and the reaction precursor of step (2) into the reactor together. The react...

Embodiment 2

[0036] Carbon cloth of the present invention supports flower-shaped Sb 2 o 4 @polyhedronSb 2 o 5 The preparation method of composite self-supporting electrode material, concrete steps comprise:

[0037] Step (1): Take 0.006g of single-layer graphene oxide powder with a sheet diameter of 0.5-5μm and a thickness of 0.8-1.2nm, put it in a mixed solution of 10mL deionized water and 20mL of deionized ethanol, and oscillate ultrasonically Get solution A;

[0038] Step (2): Add 0.57g antimony trichloride to the solution A obtained in step (1), and use 0.6mg / mL sodium hydroxide solution to adjust pH=11, continue stirring to form a reaction precursor, and use 20 ~25g / L ammonium dihydrogen phosphate is used as the electrolyte to anodize and activate the carbon cloth, the anodizing voltage is 5V, the anodizing time is 3~5min, and the activated carbon is placed in the reaction precursor and immersed for 30min;

[0039] Step (3): Transfer the carbon cloth and the reaction precursor of...

Embodiment 3

[0042] Carbon cloth of the present invention supports flower-shaped Sb 2 o 4 @polyhedronSb 2 o 5 The preparation method of composite self-supporting electrode material, concrete steps comprise:

[0043] Step (1): Take 0.003g of single-layer graphene oxide powder with a sheet diameter of 0.5-5μm and a thickness of 0.8-1.2nm, put it in a mixed solution of 10mL deionized water and 20mL of deionized ethanol, and oscillate ultrasonically Get solution A;

[0044] Step (2): Add 0.5g antimony trichloride to the solution A obtained in step (1), and use 0.5mg / mL sodium hydroxide solution to adjust pH=10, continue stirring to form a reaction precursor, and use 20 ~25g / L ammonium dihydrogen phosphate is used as the electrolyte to anodize and activate the carbon cloth. The anodizing voltage is 5V, and the anodizing time is 3-5min. The activated carbon is placed in the reaction precursor and immersed for 10min;

[0045] Step (3): Transfer the carbon cloth and the reaction precursor of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com