High-flux ceramic filter membrane and preparation method thereof

A ceramic filter membrane, high-flux technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of low bonding strength between the filter layer and the support, difficult control of membrane thickness and membrane pore size, and pore size distribution Problems such as greater influence of fibers, to achieve the effects of easy production, accurate control of thickness, and improved flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Coat PVB solution (concentration 5%, solvent is absolute ethanol) on the flat glass plate of surface with automatic coating machine, coating film thickness is 15 μ m, dry 30min at room temperature and promptly obtain polymer base film;

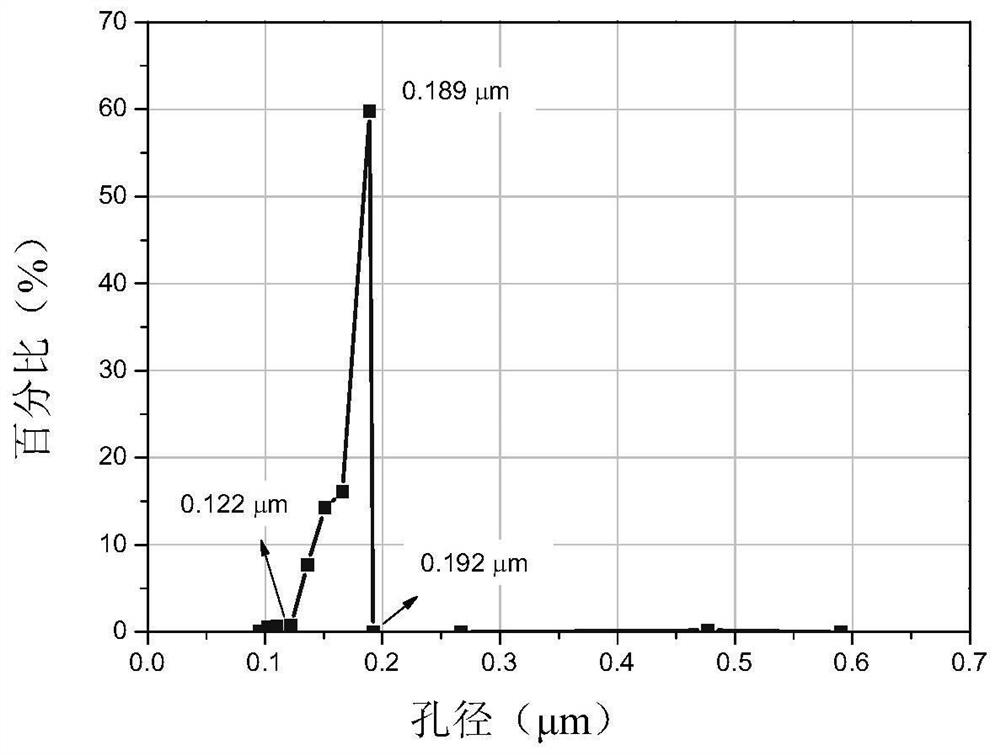

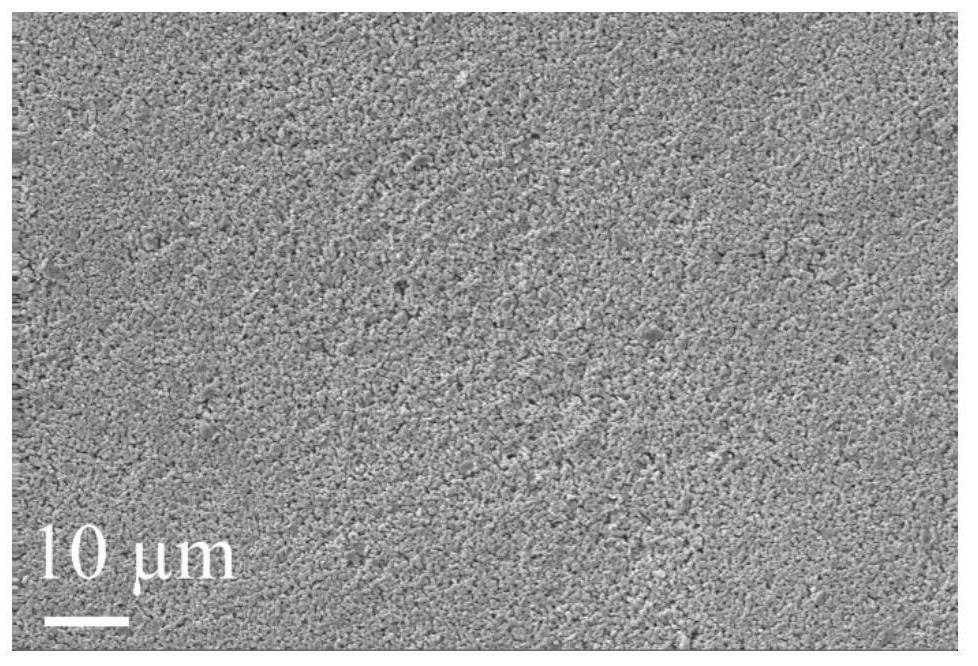

[0042] 2) will D 50760nm alumina powder (9g), deionized water (30g), silicone oil-based defoamer (0.12g), fluorocarbon surfactant (0.18g) and PAA dispersant (0.36g) were mixed and ball milled for 15min. Then add the PVA solution (21g) that concentration is 10wt%, ball mill 15min and vacuumize, obtain ceramic film coating liquid;

[0043] 3) Coating the ceramic film coating solution on the polymer base film with an automatic film coating machine, the coating thickness is 25 μm; after drying at room temperature for 12 hours, a ceramic film transfer film with a double-layer structure is obtained;

[0044] 4) Separate the ceramic film transfer film from the glass plate, and wet the ceramic support body for later use; the ceramic support...

Embodiment 2

[0048] 1) PVB solution (concentration 5wt%, solvent is absolute ethanol) is coated on the flat glass plate of surface with automatic coating machine, coating film thickness is 15 μ m, and promptly obtains polymer bottom film at room temperature drying 30min.

[0049] 2) will D 50 760nm alumina powder (9g), deionized water (30g), silicone oil-based defoamer (model Sn-1340, Japan Nopco) (0.12g), fluorocarbon surfactant (model FS-60, Shanghai Shipbang Industrial Co., Ltd.) (0.18g) and PAA dispersant (0.36g) were mixed and ball milled for 15min, and then a PVA solution (21g) with a concentration of 10wt% was added, ball milled for 15min and vacuumized to obtain a ceramic film coating liquid;

[0050] 3) Coating the ceramic film coating solution on the polymer base film with an automatic film coating machine, the coating thickness is 40 μm, and after drying at room temperature for 12 hours, a ceramic film transfer film with a double-layer structure is obtained;

[0051] 4) Separat...

Embodiment 3

[0055] 1) Coat PVB solution (concentration 5%, solvent is absolute ethanol) on the flat glass plate of surface with automatic coating machine, coating film thickness is 15 μ m, dry 30min at room temperature, promptly obtain polymer base film;

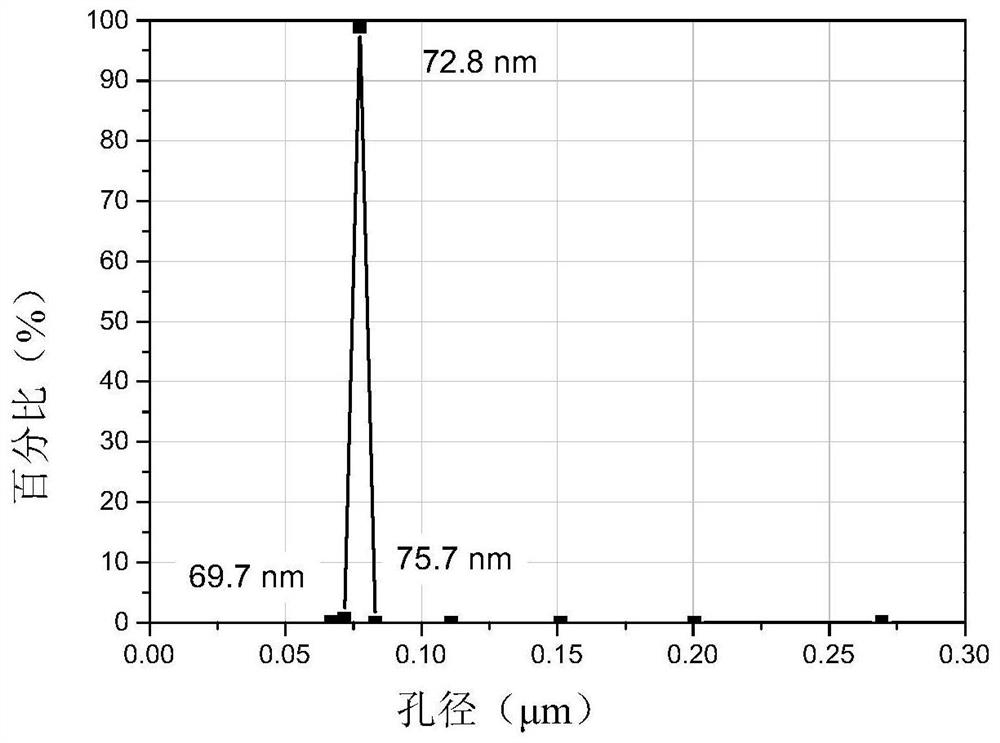

[0056] 2) will D 50 Mix 500nm zirconia powder (10.2g), deionized water (25.8g), silicone oil-based defoamer (0.12g), fluorocarbon surfactant (0.18g) and PAA dispersant (0.36g) and ball mill for 15min , then adding a concentration of 10% PVA solution (24g), ball milled for 15min and vacuumized to obtain a ceramic membrane coating solution;

[0057] 3) Coating the ceramic film coating solution on the polymer base film with an automatic film coating machine, the coating thickness is 25 μm, and drying at room temperature for 12 hours to obtain a ceramic film transfer film with a double-layer structure;

[0058] 4) Separate the transfer film from the glass plate, and wet the ceramic support for later use; the ceramic support used is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com