Spiral scraping dosing mixing catalytic oxidizer and sludge utilization method

A catalytic oxidizer and catalytic oxidation technology, applied in the environmental field, can solve problems such as hazards and non-substantial utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] This embodiment provides a spiral scraping and dosing mixed catalytic oxidizer.

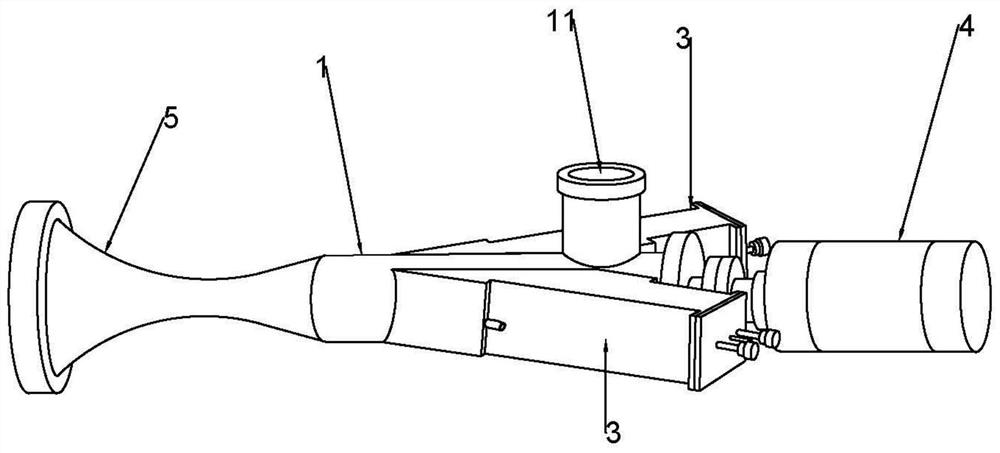

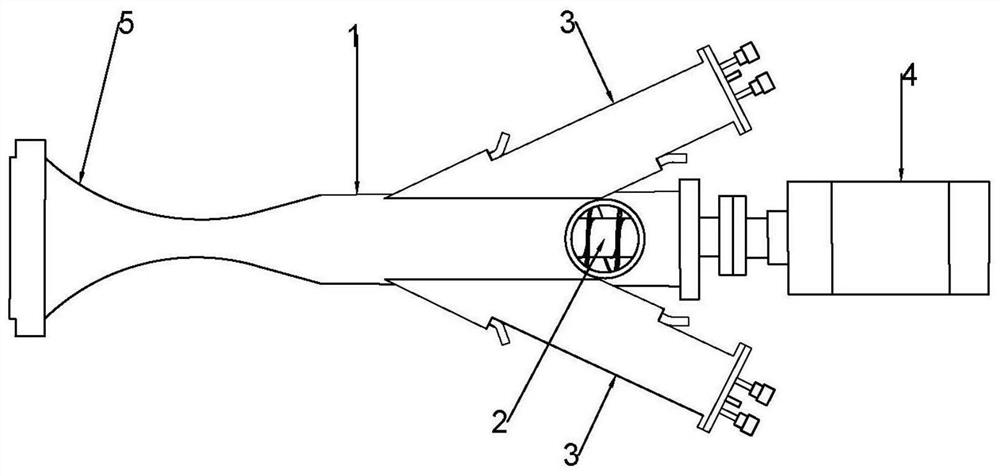

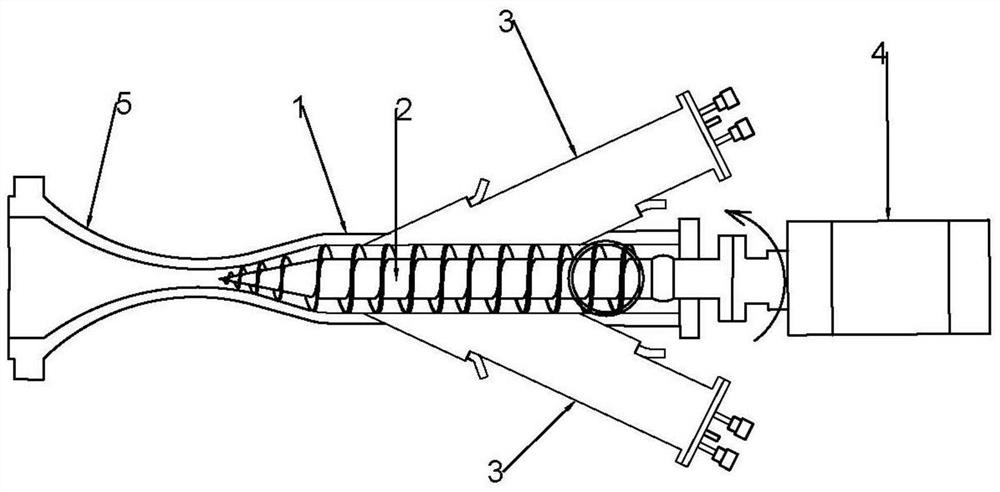

[0092] A spiral scraping and dosing mixed catalytic oxidizer, its structure diagram is shown in figure 1 , figure 2 and image 3 The spiral scraping and dosing mixed catalytic oxidizer includes a spiral scraping and dosing mixed catalytic oxidizer housing 1, a spiral scraping and pushing mixing knife 2, a semi-sacrificial catalytic oxidation dosing device 3 and a driving motor 4;

[0093] One end of the shell 1 of the spiral scraping and dosing mixed catalytic oxidizer is provided with a feed liquid inlet 11, and the other end is provided with a variable pressure outlet 5; at the end where the feed liquid inlet is provided, a drive motor 4 is provided, and the drive motor 4 and the spiral scraping pusher are provided. The mixing knife 2 is coaxially connected, the driving motor 4 is used to drive the spiral scraping and pushing, the mixing knife 2 rotates and cuts, and the semi-sacrific...

Embodiment 2

[0119] This embodiment provides a sludge utilization device and a sludge utilization method.

[0120] This embodiment provides a sludge utilization equipment, including the spiral scraping and dosing mixed catalytic oxidizer of embodiment 1, and also includes a sludge pump and a solid-liquid separation device; wherein the discharge port of the sludge pump and the spiral scraping and dosing The feed liquid inlet 11 of the mixed catalytic oxidizer is connected, and the solid-liquid separation device is connected with the variable pressure outlet 5 of the spiral scraping and dosing mixed catalytic oxidizer.

[0121] A method for sludge utilization, using the above sludge utilization equipment, comprising the following steps:

[0122] step one:

[0123] Turn on the sludge pump and the drive motor 4 of the device. Under the action of the pump pressure, the sludge enters the spiral scraping and dosing mixed catalytic oxidizer from the feed liquid inlet 11, and the spiral scraping p...

Embodiment 3

[0140] This example provides a method for preparing a sludge-based catalyst.

[0141] Utilize the spiral scraping dosing mixed catalytic oxidizer of embodiment 1, according to the use method of embodiment 2, process the excess sludge discharged from a certain municipal sewage treatment plant, the mass percentage content of the first agent supply system is used in the first agent tank Be 30% hydrogen peroxide; Fill the saturated solution of the 3mol / L sulfuric acid solution of ferrous sulfate in the second medicament tank of the second medicament supply system; The ozone generator maximum production ozone amount of the 3rd medicament supply system is the oxygen of 10g / h Source adjustable ozone generator, the amount of ozone is 6g / h. Liquid fertilizer 2 and sludge-based catalyst 2 were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com