Photochromic naphthalimide Cd-MOF, preparation method thereof, photochromic printing paste and application

A naphthalimide-based, photochromic technology, applied in the fields of its preparation, photochromic printing paste, and photochromic naphthalimide-based Cd-MOF, can solve the problem of poor fatigue resistance, damage to user comfort, The problem of limited interaction is achieved, and the preparation method is simple, easy to operate, easy to operate, and has broad development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 0.1mmol of Cd(NO 3 ) 2 4H 2 O, 0.1 mmol of H 2 NDI and 0.1 mmol H 2 BDC is ultrasonically dissolved in a mixed organic solvent, the mixed organic solvent is a mixed solvent of N,N-dimethylformamide and deionized water, and the volume percentage of N,N-dimethylformamide and deionized water is 2:8 ;

[0034] (2) The above solution was placed in an oven at 120°C for solvothermal reaction for 48 hours to obtain a yellow blocky crystalline material, and then the photochromic naphthalimide-based Cd-MOF was obtained by solid-liquid separation.

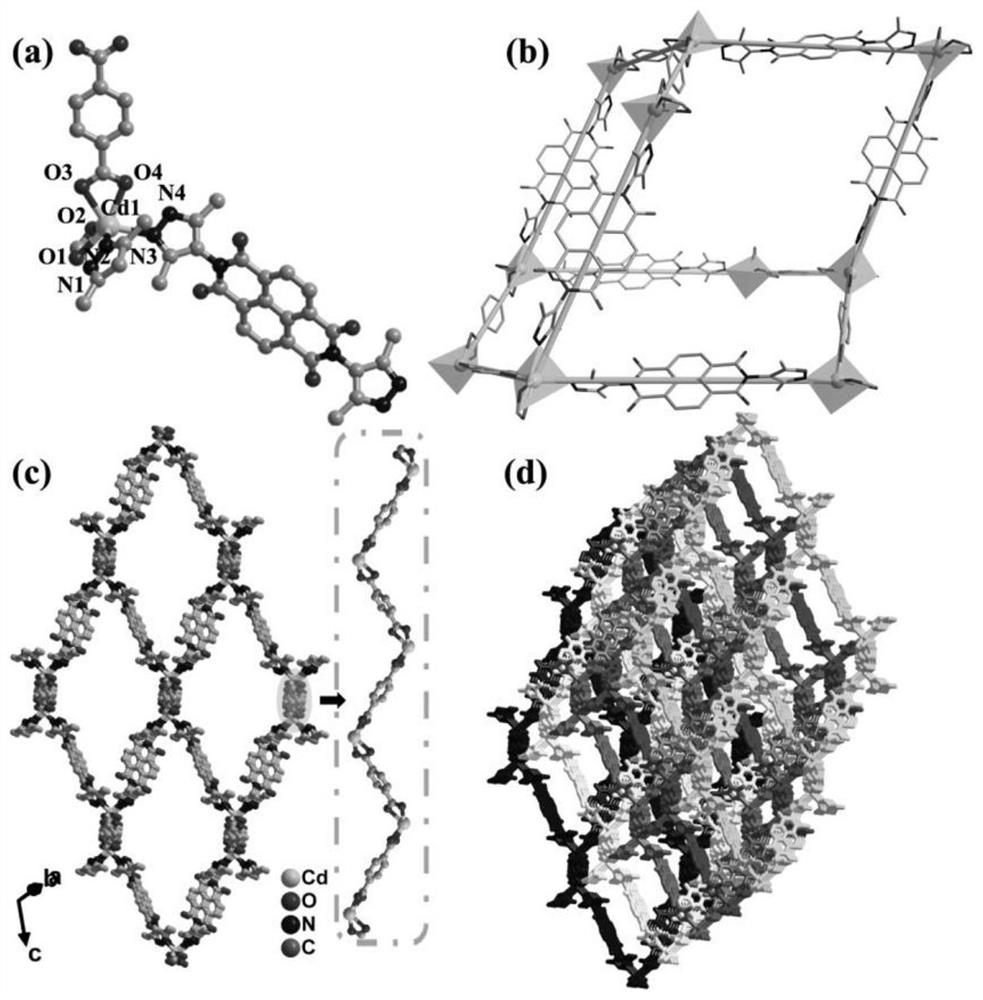

[0035] figure 1 It is the crystal structure diagram of the photochromic naphthalimide-based Cd-MOF in Example 1. It can be seen from the single crystal X-ray crystal structure analysis that: Cd-MOF belongs to the triclinic space group P-1, and Cd-MOF does not The symmetric unit is composed of a Cd(II) ion, a H 2 NDI ligand, and a BDC 2- composition. in H 2 In the NDI ligand, only two nitrogen atoms in the 3,5-dimethyl...

Embodiment 2

[0039] (1) Add 0.1mmol of CdSO 4 8 / 3H 2 O, 0.1 mmol of H 2 NDI and 0.1 mmol H 2 BDC is ultrasonically dissolved in a mixed organic solvent, the mixed organic solvent is a mixed solvent of N,N-dimethylformamide and deionized water, and the volume percentage of N,N-dimethylformamide and deionized water is 2:8 ;

[0040] (2) The above solution was placed in an oven at 120°C for solvothermal reaction for 48 hours to obtain a yellow microcrystalline material, and then solid-liquid separation was performed to obtain a photochromic naphthalimide-based Cd-MOF.

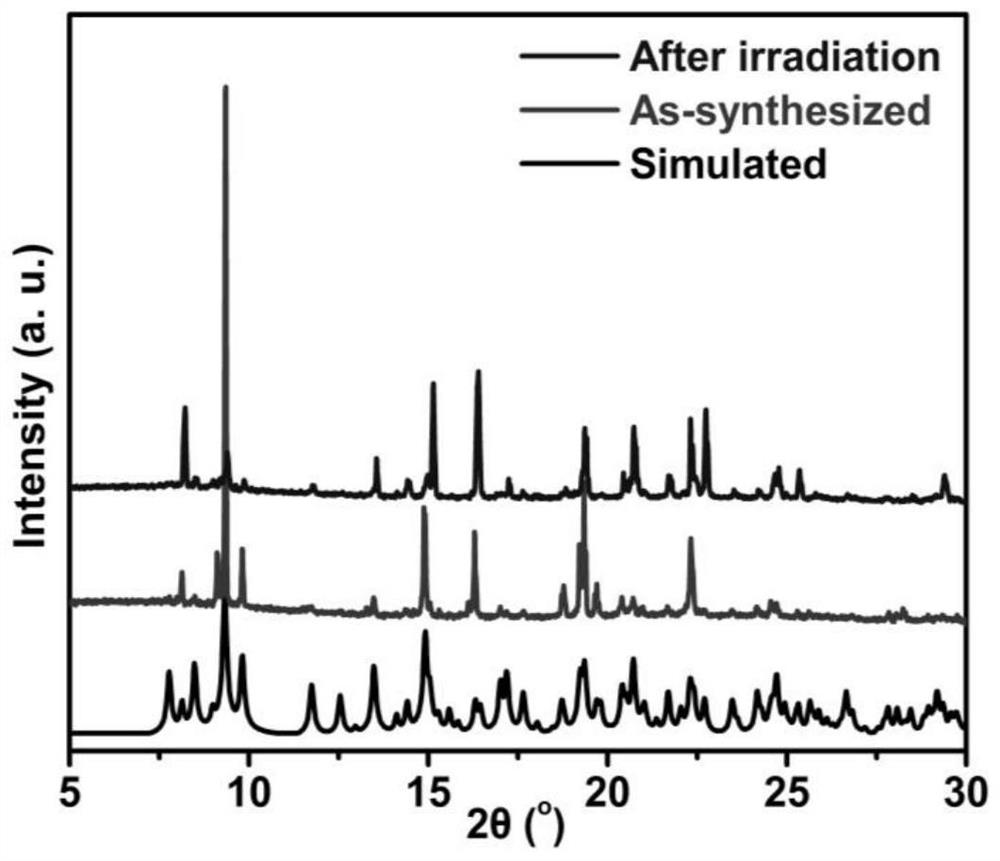

[0041] Due to the small size of the microcrystalline material, it is difficult to test its specific structure by an instrument. Therefore, the powder diffraction pattern (XRD) of the microcrystalline material is directly tested by powder X-ray diffraction test, and compared with the XRD pattern of the ligand and metal salt, it is found that the microcrystalline The XRD pattern of the material does not recombine with its li...

Embodiment 3

[0043] (1) 0.1mmol of CdCl 2 ·5 / 2H 2 O, 0.1 mmol of H 2 NDI and 0.1 mmol H 2 BDC is ultrasonically dissolved in a mixed organic solvent, the mixed organic solvent is a mixed solvent of N,N-dimethylformamide and deionized water, and the volume percentage of N,N-dimethylformamide and deionized water is 2:8 ;

[0044] (2) The above solution was placed in an oven at 120° C. for solvothermal reaction for 48 h to obtain a yellow powder material, and then solid-liquid separation was performed to obtain a photochromic naphthalimide-based Cd-MOF.

[0045] Due to the small particle size of the powder material, it is difficult to test its specific structure through the instrument, so the powder diffraction pattern (XRD) is directly measured by powder X-ray diffraction test, and compared with the XRD pattern of the ligand, metal salt and block crystal, It was found that the XRD patterns of the powder material and the ligand were basically consistent, indicating that no coordination re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com