A green pigment with low lightness and high near-infrared reflectivity and preparation method thereof

A green pigment and near-infrared technology, applied in the field of composite inorganic pigments, can solve problems such as difficulty in maintaining the green tone of chrome green pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

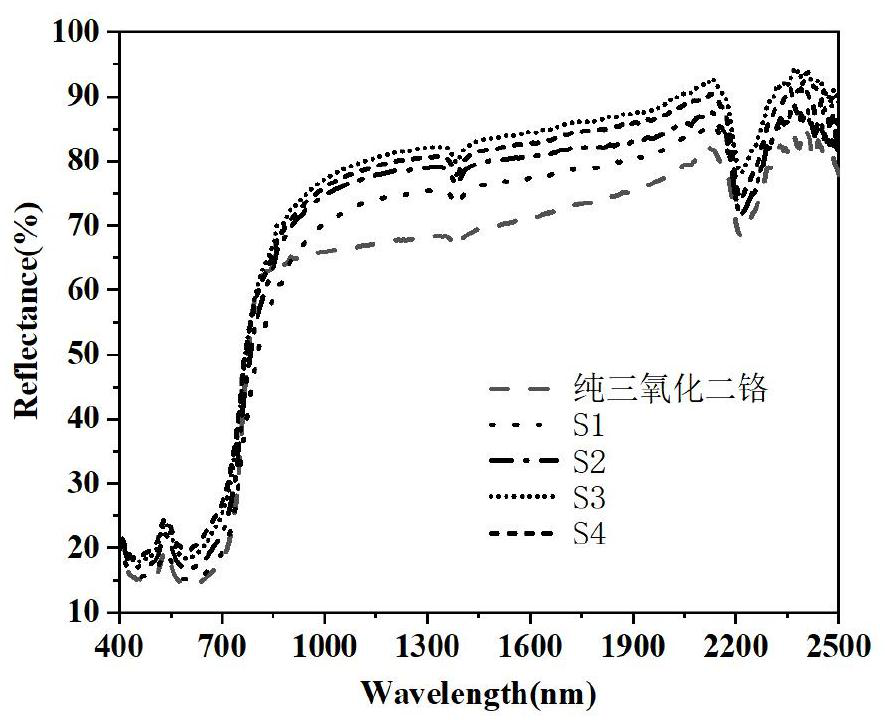

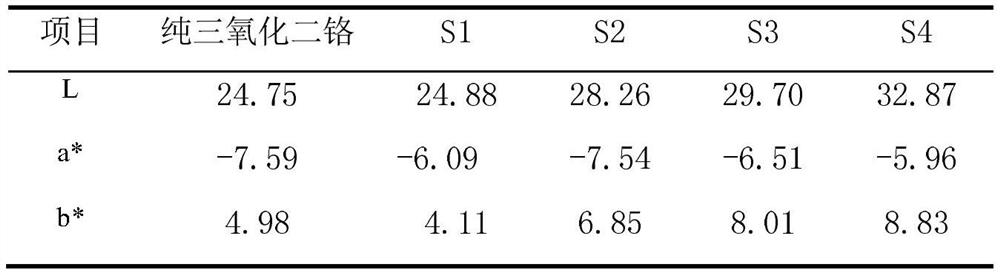

Embodiment 1

[0018] Weigh the following raw materials according to mass percentage: chromium trioxide, 29.14g; manganese dioxide, 0.86g; then press the ball: material: ethanol=4:1:1 weigh zirconium ball, 120g; ethanol, 30g, add the ball mill together , using ethanol as the ball milling medium, using planetary wet ball milling to mix evenly, drying and grinding, passing through a 100-mesh sieve to remove large particles, and then placing it in a horse boiling furnace for solid-phase reaction. Gradually rise from room temperature to 1200°C, keep warm and cool to room temperature with the furnace. Finally, the powder is ground and sieved to obtain the green pigment S1.

Embodiment 2

[0020] Weigh the following raw materials according to mass percentage: chromium trioxide, 28.29g; manganese dioxide, 1.71g; then press the ball: material: ethanol=4:1:1 weigh zirconium ball, 120g; ethanol, 30g, add the ball mill together , using ethanol as the ball milling medium, using planetary wet ball milling to mix evenly, drying and grinding, passing through a 100-mesh sieve to remove large particles, and then placing it in a horse boiling furnace for solid-phase reaction. Gradually rise from room temperature to 1200°C, keep warm and cool to room temperature with the furnace. Finally, the powder is ground and sieved to obtain the green pigment S2.

Embodiment 3

[0022] Weigh the following raw materials according to mass percentage: chromium trioxide, 26.61g; manganese dioxide, 3.38g; then press the ball: material: ethanol=4:1:1 weigh zirconium ball, 120g; ethanol, 30g, add the ball mill together , using ethanol as the ball milling medium, using planetary wet ball milling to mix evenly, drying and grinding, passing through a 100-mesh sieve to remove large particles, and then placing it in a horse boiling furnace for solid-phase reaction. Gradually rise from room temperature to 1200°C, keep warm and cool to room temperature with the furnace. Finally, the powder is ground and sieved to obtain the green pigment S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com