Fireproof insulating coating and preparation method thereof

A technology for insulating coatings and coatings, applied in fire-resistant coatings, insulators, coatings, etc., can solve the problems of unsatisfactory dispersion uniformity of silica particles and poor toughness of insulating films, and achieve uniform dispersion and good coating properties. , the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

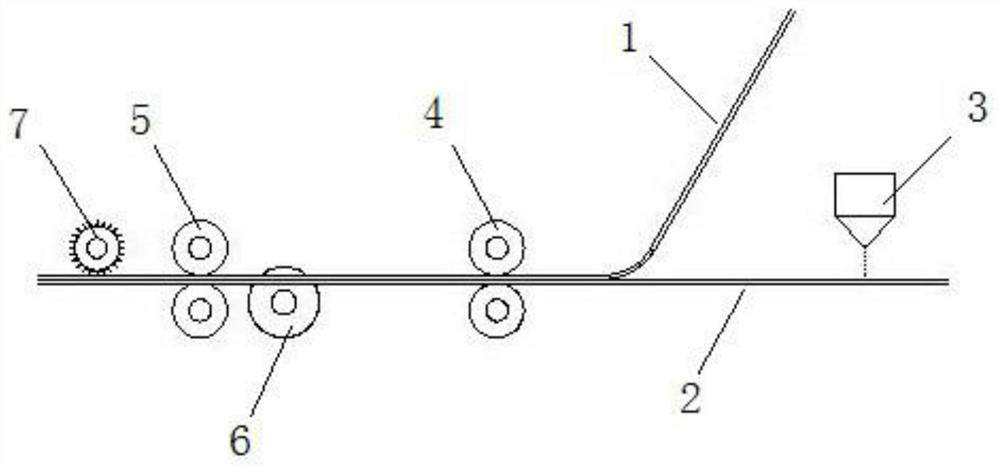

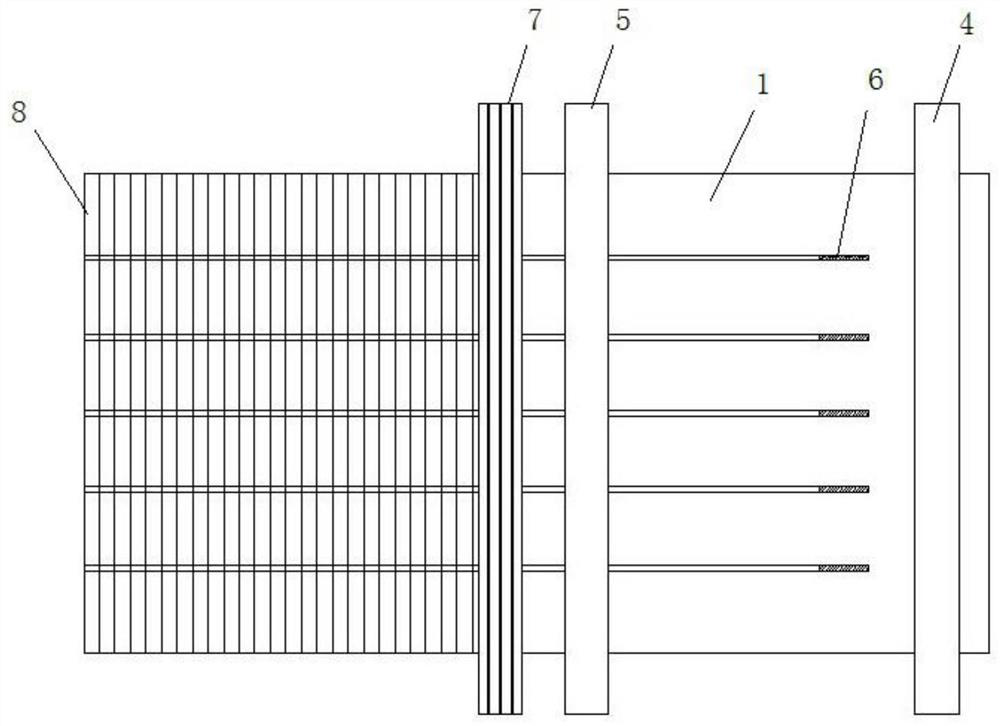

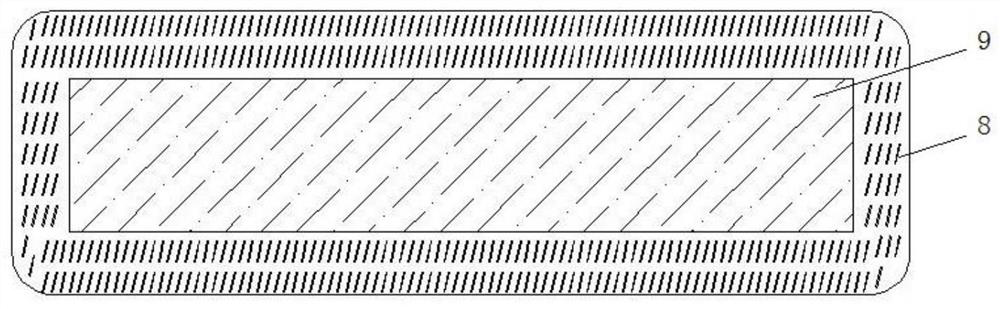

[0031] This embodiment provides a kind of fireproof insulating coating, and this insulating coating is the insulating coating used for the insulated wire that is provided with insulating film on the conductor 9 that has quadrilateral section, and insulating coating is made of polyamide-imide resin coating and organosilicon sol Formed by mixing, the polyamideimide resin coating comprises a solvent and a polyamideimide resin.

[0032] In this embodiment, the polyamide-imide resin paint is formed by dissolving polyamide-imide resin in a solvent containing cyclic ketones having a boiling point in the range of 130° C. to 180° C., and the cyclic ketones include cycloheptanone. , at least one of cyclohexanone and cyclopentanone.

[0033] In this embodiment, the organosilicon sol in the polyamide-imide resin accounts for 35% by weight. Organosilicon sol includes 25% by weight of adhesive tape 8, and the dispersion solvent of organosilicon sol is cyclic ketones with a boiling point in...

Embodiment 2

[0042] This embodiment provides a kind of fireproof insulating coating, and this insulating coating is the insulating coating used for the insulated wire that is provided with insulating film on the conductor 9 that has quadrilateral section, and insulating coating is made of polyamide-imide resin coating and organosilicon sol Formed by mixing, the polyamideimide resin coating comprises a solvent and a polyamideimide resin.

[0043] In this embodiment, the polyamide-imide resin paint is formed by dissolving polyamide-imide resin in a solvent containing cyclic ketones having a boiling point in the range of 130° C. to 180° C., and the cyclic ketones include cycloheptanone. , at least one of cyclohexanone and cyclopentanone.

[0044] In this embodiment, the organosilicon sol in the polyamide-imide resin accounts for 30% by weight. Organosilicon sol includes 20% by weight of adhesive tape 8, and the dispersion solvent of organosilicon sol is cyclic ketones with a boiling point in...

Embodiment 3

[0053] This embodiment provides a kind of fireproof insulating coating, and this insulating coating is the insulating coating used for the insulated wire that is provided with insulating film on the conductor 9 that has quadrilateral section, and insulating coating is made of polyamide-imide resin coating and organosilicon sol Formed by mixing, the polyamideimide resin coating comprises a solvent and a polyamideimide resin.

[0054] In this embodiment, the polyamide-imide resin paint is formed by dissolving polyamide-imide resin in a solvent containing cyclic ketones having a boiling point in the range of 130° C. to 180° C., and the cyclic ketones include cycloheptanone. , at least one of cyclohexanone and cyclopentanone.

[0055] In this embodiment, the organosilicon sol in the polyamide-imide resin accounts for 40% by weight. Organosilicon sol includes 30% by weight of adhesive tape 8, and the dispersion solvent of organosilicon sol is cyclic ketones with a boiling point in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com