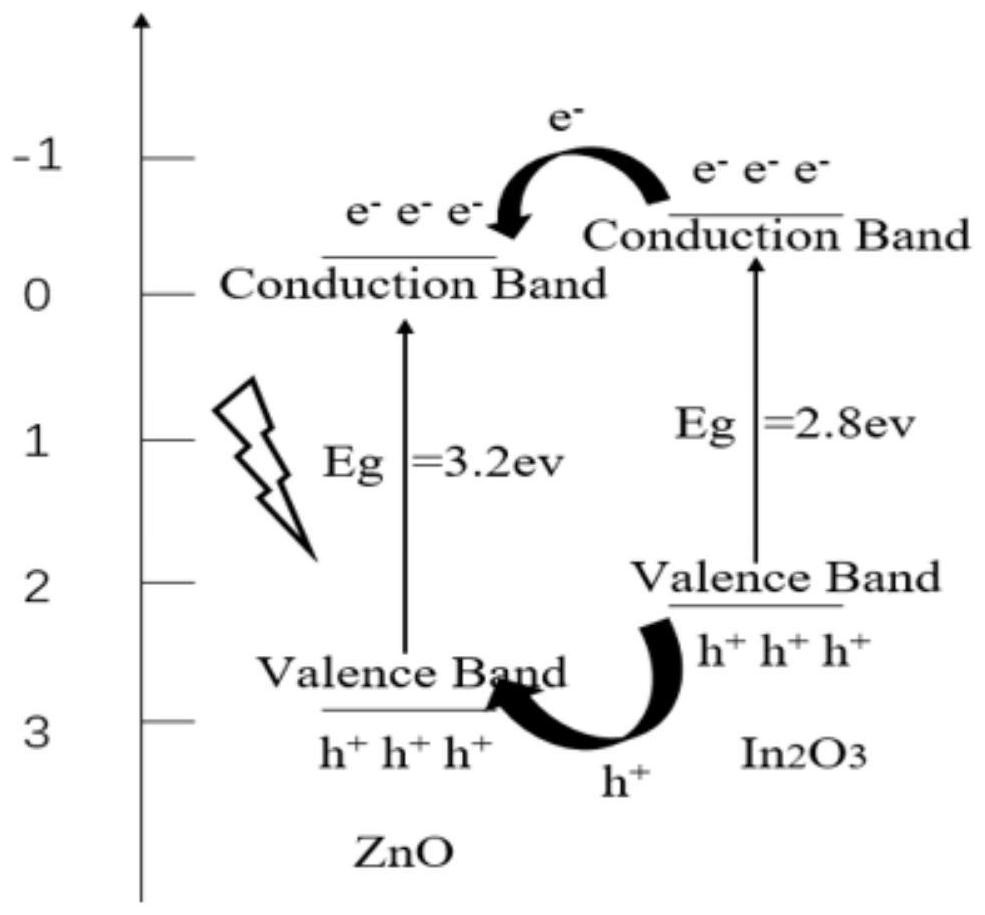

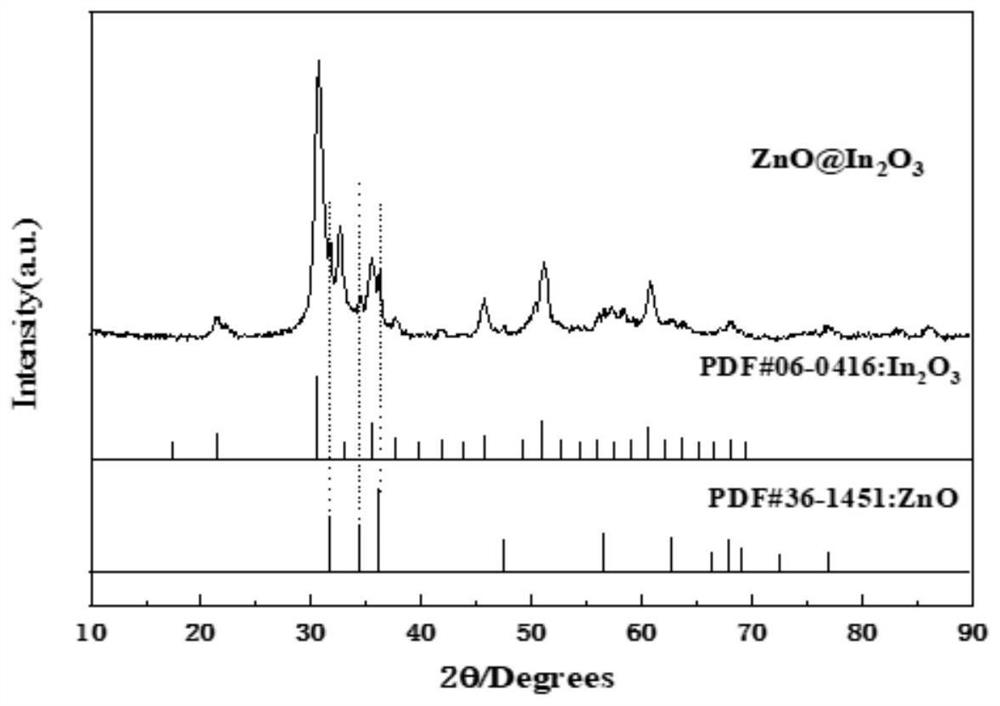

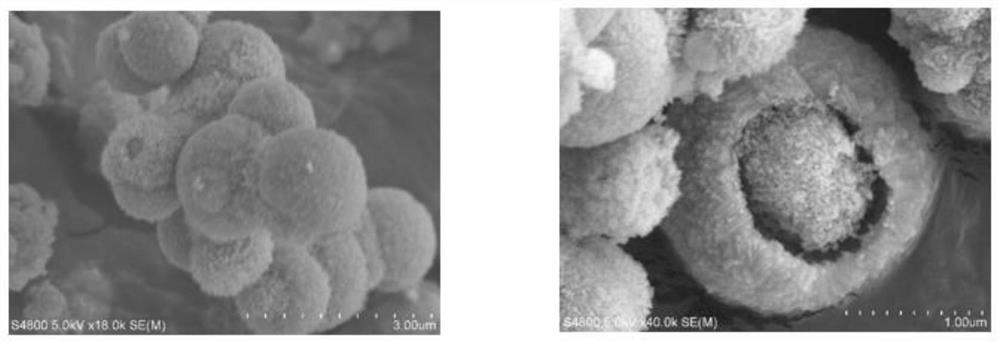

ZnO/In2O3 heterogeneous II-type photocatalytic material with hollow core-shell structure and preparation method thereof

A technology of photocatalytic materials and core-shell structure, which is applied in the field of photocatalytic material preparation, can solve the problems of complex experimental process and easy collapse of spheres, and achieve the effects of simple operation, environmental friendliness, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0039] Implementation Case 1: A Hollow Core-Shell Structure ZnO / In 2 o 3 Preparation method of heterogeneous type Ⅱ photocatalytic material

[0040] Weigh 0.59g of zinc nitrate, 0.38g of indium nitrate and stir to dissolve in a mixed solution containing 20mL of ethylene glycol, 20mL of polyethylene glycol and 10mL of distilled water, add 0.8g of sodium citrate, 1.5g of Stir the urea for 3 hours, transfer the stirred mixed solution to a high-pressure reactor, heat it at 200°C for 12 hours, take the product after the hydrothermal reaction and centrifuge it at 8,000 rpm for 8 minutes, wash the centrifugate three times with distilled water, wash it twice with ethanol, and then dry it at 60°C After 600 min, the dried sample was calcined in a tube furnace at 500°C for 180 min.

Embodiment example 2

[0042] Weigh 0.59g of zinc nitrate, 0.38g of indium nitrate and stir to dissolve in a mixed solution containing 20mL of ethylene glycol, 20mL of polyethylene glycol and 10mL of distilled water, add 0.9g of sodium citrate, 1.5g Stir the urea for 3 hours, transfer the stirred mixed solution to a high-pressure reactor, heat it at 200°C for 12 hours, take the product after the hydrothermal reaction and centrifuge it at 8,000 rpm for 8 minutes, wash the centrifugate three times with distilled water, wash it twice with ethanol, and then dry it at 60°C After 600 min, the dried sample was calcined in a tube furnace at 500°C for 180 min.

Embodiment example 3

[0044]Weigh 0.59g of zinc nitrate and 0.38g of indium nitrate and stir and dissolve them in a mixed solution containing 20mL of ethylene glycol, 20mL of polyethylene glycol and 10mL of distilled water. Add 1.0g of sodium citrate, 1.5g of Stir the urea for 3 hours, transfer the stirred mixed solution to a high-pressure reactor, heat it at 200°C for 12 hours, take the product after the hydrothermal reaction and centrifuge it at 8,000 rpm for 8 minutes, wash the centrifugate three times with distilled water, wash it twice with ethanol, and then dry it at 60°C After 600 min, the dried sample was calcined in a tube furnace at 500°C for 180 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com