Polymer molecular cluster nano composite catalytic material as well as preparation method and application thereof

A nanocomposite and catalytic material technology, applied in the field of polymer molecular cluster nanocomposite catalytic materials and their preparation, can solve the problems of lack of efficient catalysts, difficult to contact the catalytic center, and the material swelling rate reduces the reaction substrate, etc., and achieves product process quality. Easy to control, conducive to industrial production, and avoid the effect of reducing catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

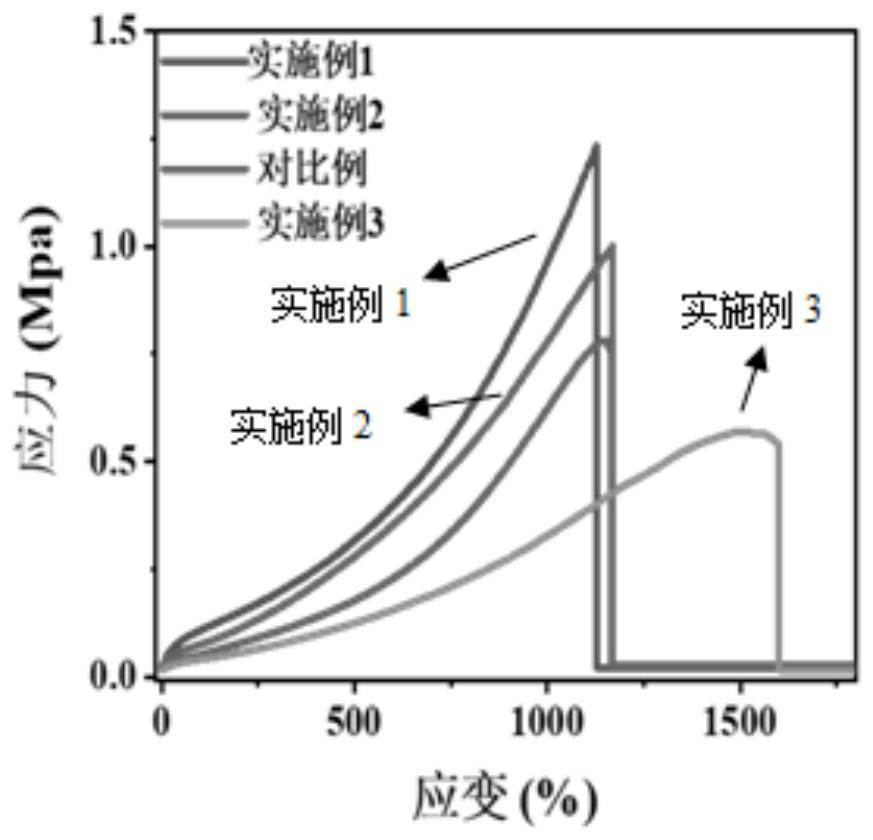

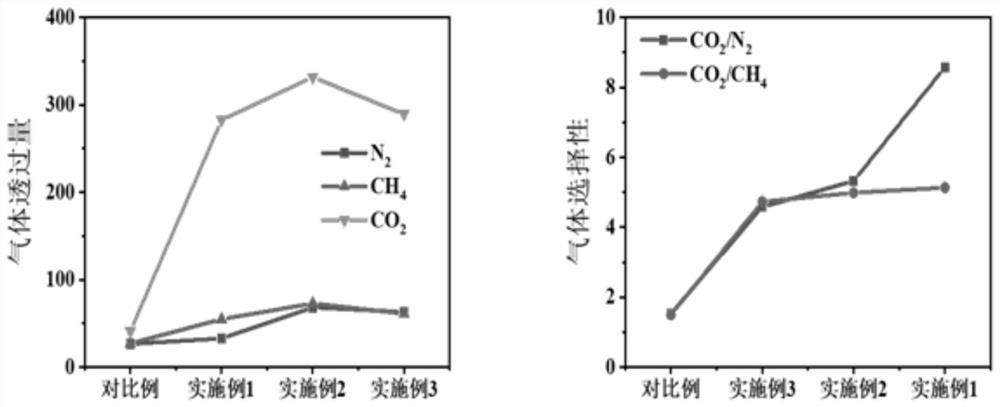

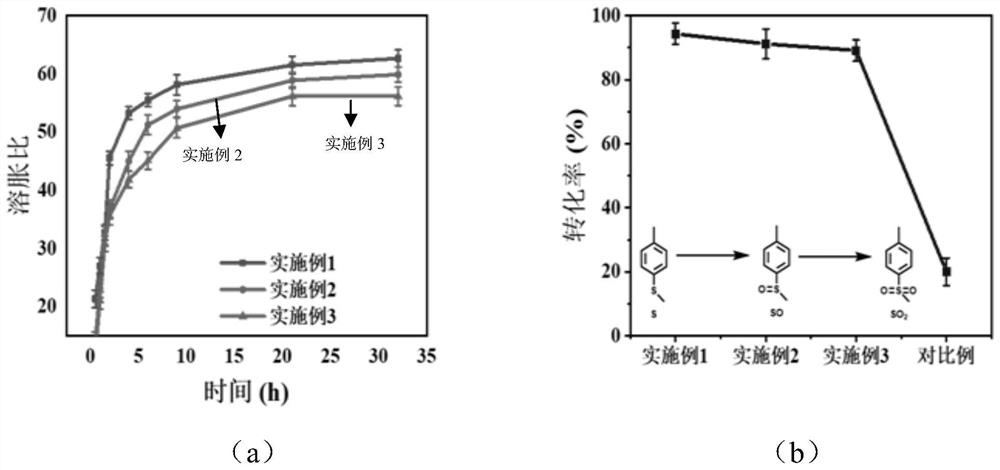

[0039] Example 1 Methyl methacrylate (1.35ml), n-butyl acrylate (5.94ml), MAHVs (0.35g) and initiator (50mg) were dissolved in 12ml of DMF and heated to 65°C for two hours.

Embodiment 2

[0040] Example 2 Methyl methacrylate (2.65ml), n-butyl acrylate (3.94ml), MAHVs (0.35g) and initiator (50mg) were dissolved in 12ml of DMF and heated to 65°C for two hours.

Embodiment 3

[0041]Example 3 Methyl methacrylate (3.9ml), n-butyl acrylate (1.94ml), MAHVs (0.35g) and initiator (50mg) were dissolved in 12ml of DMF and heated to 65°C for two hours.

[0042] The polymer molecular cluster nanocomposite catalytic materials obtained in the above Examples 1-3 are all yellow and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com