Laser preparation method of self-cleaning antibacterial glass

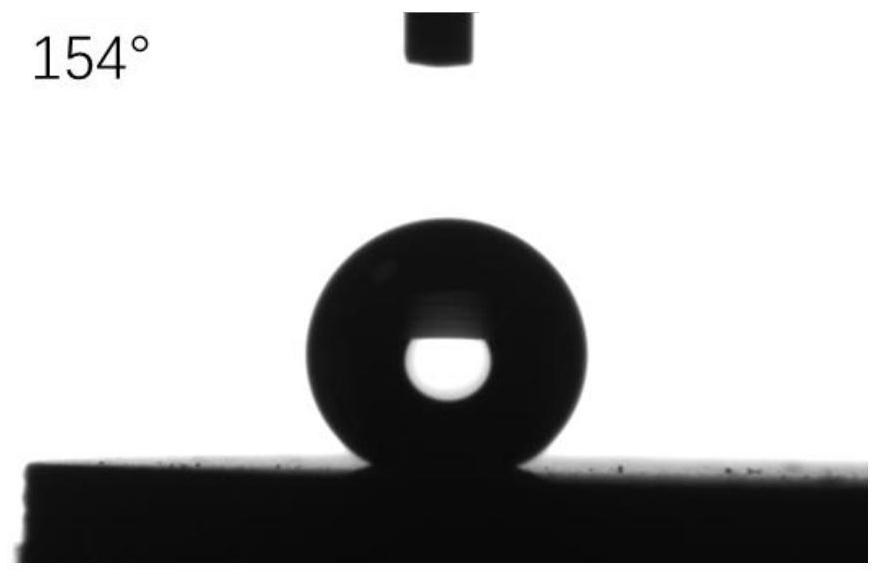

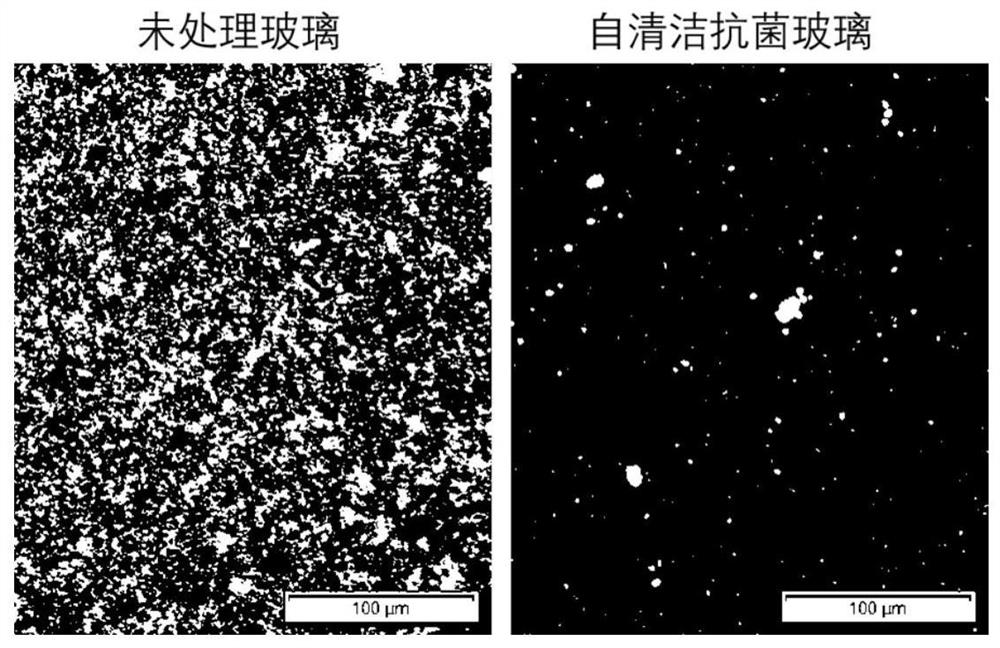

An antibacterial glass and self-cleaning technology, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of thermal damage on the glass surface, limited types of microstructures, and increased processing difficulty, so as to prevent thermal damage, Excellent self-cleaning effect, reducing cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

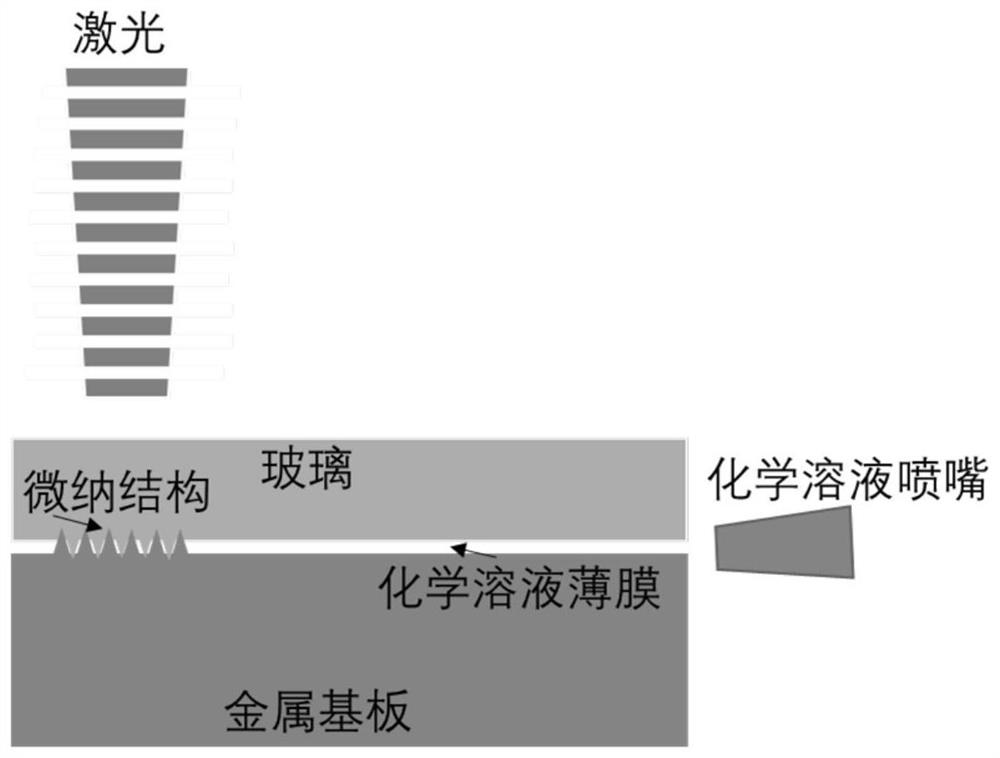

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Grinding and polishing the tempered glass and copper substrate surface, ultrasonic cleaning with alcohol and acetone for 10 minutes, and drying;

[0037] Step 2, configure AgNO 3 solution, the solubility is 1.5M;

[0038] Step 3, use a water gun to wash the prepared solution on the surface of the copper substrate, and at the same time slowly cover the tempered glass on the surface of the copper substrate;

[0039] Step 4, place the surface-treated tempered glass and the copper substrate sample under the femtosecond laser (wavelength 1064nm) for laser-induced surface micro-nano structure processing. The laser processing parameters are set as: power 8W, pulse width 500fs, The frequency is 400kHz, the scanning speed is 800mm / s, the scanning distance is 35μm, scanning 5 times, and the microcone structure covered with silver nanoparticles is obtained on the tempered glass surface;

[0040] Step five, move the glass vertically upward from the metal substrate;

[00...

Embodiment 2

[0043] Step 1: Polish the surface of ordinary glass and titanium substrates, ultrasonically clean them with alcohol and acetone for 10 minutes, and dry them;

[0044] Step 2, configure AuCl 4 solution, the solubility is 0.5M;

[0045] Step 3: Use a water gun to wash the configured solution on the surface of the titanium substrate, and at the same time slowly cover the surface of the copper substrate with ordinary glass;

[0046] Step 4, place the surface-treated ordinary glass and the titanium substrate sample under a femtosecond laser (wavelength 1064nm) for laser-induced surface micro-nano structure processing. The laser processing parameters are set as follows: power 5W, pulse width 800fs, The frequency is 200kHz, the scanning speed is 1000mm / s, the scanning distance is 30μm, scanning 5 times, and the microcone structure covered with gold nanoparticles is obtained on the surface of ordinary glass;

[0047] Step five, move the glass vertically upward from the metal substra...

Embodiment 3

[0050] Step 1: Polish the surface of plexiglass and stainless steel substrate, ultrasonically clean with alcohol and acetone for 10 minutes, and dry;

[0051] Step 2, configure CuCl solution with a solubility of 1.0M;

[0052] Step 3: Use a water gun to wash the prepared solution on the surface of the stainless steel substrate, and at the same time slowly cover the surface of the copper substrate with plexiglass;

[0053] Step 4, place the surface-treated plexiglass and the stainless steel substrate sample under a femtosecond laser (wavelength 1064nm) for laser-induced surface micro-nanostructure processing. The laser processing parameters are set to: power 7W, pulse width 100fs, The frequency is 300kHz, the scanning speed is 1500mm / s, the scanning distance is 40μm, scanning 10 times, and the microcone structure covered with copper nanoparticles is obtained on the tempered glass surface;

[0054] Step five, move the glass vertically upward from the metal substrate;

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com