Synthesis method and application of UV-cured bactericidal anti-static resin material

A resin material and anti-static technology, which is applied in the field of synthesis of UV-cured sterilizing and anti-static resin materials, can solve the problems of unsustainable antibacterial effect, migration of antibacterial agents, poor heat resistance, etc. good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

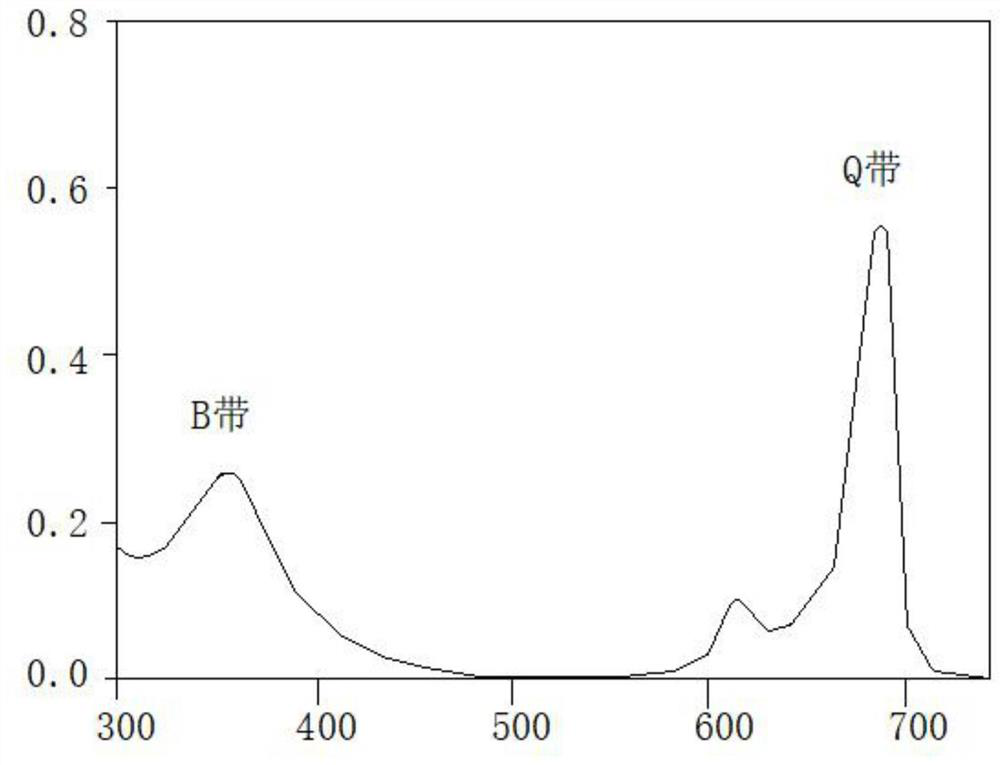

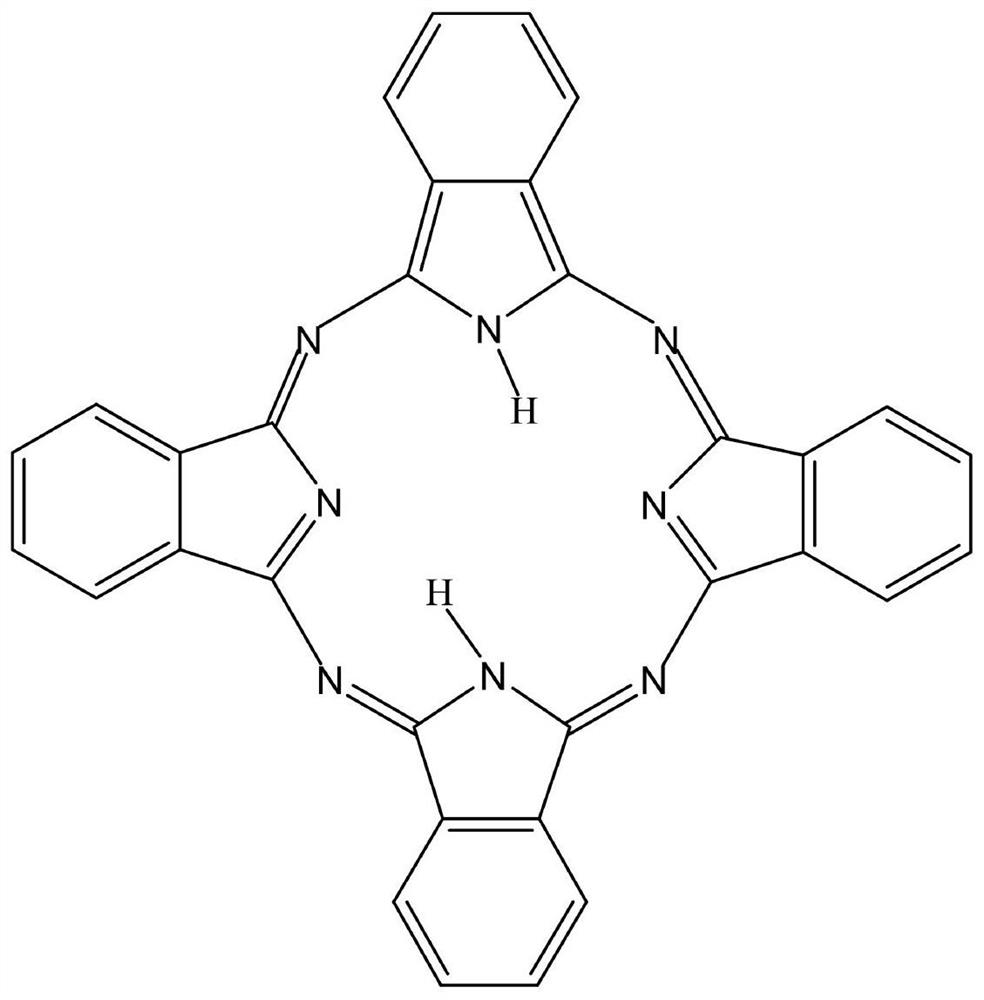

[0060] In step 1, the preparation method of zinc tetranitrophthalocyanine solid powder comprises the following steps:

[0061] Step 1.1, respectively add 20-25% of 4-nitrophthalonitrile, 5-10% of zinc acetate dihydrate, and 65-75% of ethylene glycol into a three-necked flask equipped with a stirrer;

[0062] Step 1.2. Fill the three-necked flask with nitrogen and then seal the reaction under the heating condition of 140-160°C for 22-26 hours. After the system is cooled, take it out into the methanol solution;

[0063] Step 1.3: perform suction filtration and washing in sequence until the filtrate is colorless, and vacuum-dry at 45-55° C. to obtain the zinc tetranitrophthalocyanine solid powder.

[0064] In step 2, the preparation method of tetraaminophthalocyanine zinc solid powder comprises the following steps:

[0065] Step 2.1, respectively adding 10-15% of the zinc tetranitrophthalocyanine solid powder obtained in step 1.3, 45-55% of sodium sulfide nonahydrate, and 35-40%...

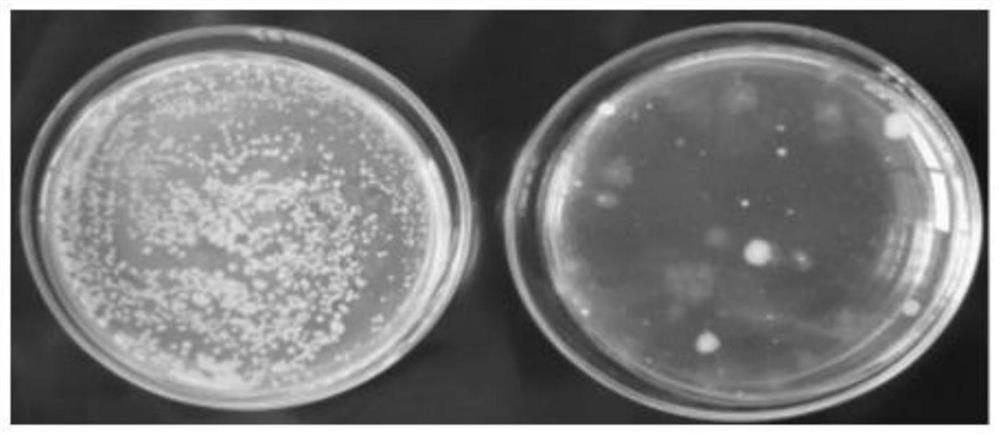

Embodiment 1

[0103] Add 33.12g of 4-nitrophthalonitrile, 10.5g of zinc acetate dihydrate, and 95.64g of ethylene glycol into a three-necked flask equipped with a stirrer, fill it with nitrogen, and conduct a sealed reaction under heating at 150°C for 24 hours. After the system was cooled, it was added to methanol solution, then suction filtered, washed until the filtrate was colorless, and finally dried in vacuum at 50°C to obtain a dark green powder, which was zinc tetranitrophthalocyanine solid.

[0104]

[0105] Add 33.53g of the above-mentioned prepared tetranitrophthalocyanine zinc solid product, 128.2g sodium sulfide nonahydrate, and 100ml dimethylformamide into a three-necked flask equipped with a stirrer, start to heat up and stir slowly, and the temperature rises to At 60°C, all zinc tetranitrophthalocyanines were dissolved in dimethylformamide, and at this time, the stirring speed was increased and the temperature was kept constant for 1 hour. After the reaction was completed,...

Embodiment 2

[0112] Add 32.2g of 4-nitrophthalonitrile, 19.5g of silver acetate, and 85.4g of ethylene glycol into a three-necked flask equipped with a stirrer, fill it with nitrogen, and conduct a sealed reaction at 140°C for 22 hours, and wait for the system to cool Afterwards, it was added into methanol solution, then suction-filtered, washed until the filtrate was colorless, and vacuum-dried at 45°C to obtain a solid powder of silver tetranitrophthalocyanine.

[0113]

[0114] Add 36.5 g of the silver tetranitrophthalocyanine solid product prepared above, 118.2 g of sodium sulfide nonahydrate, and 90 ml of dimethylformamide into a three-necked flask equipped with a stirrer, start to heat up and stir slowly, and the temperature rises to 55 ℃, allowing all the silver tetranitrophthalocyanine to be dissolved in dimethylformamide, at this time, increase the stirring speed and keep the constant temperature for 0.8 hours. After the reaction was completed, the reaction solution was poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com