Rapid ionization device and preparation method thereof

A device and ionization technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of long-term stable operation of unfavorable devices, large device on-state loss, high residual voltage, and reduce the range of crossing , The effect of improving the turn-on speed and reducing the residual voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides the preparation method of described fast ionization device, comprises the following steps:

[0045] (1) Impurity diffusion is performed on the cleaned n-type Si sheet to form a PNP structure; then the p region on one side is removed by a thinning machine to obtain a PN structure comprising a p base region 4 and an n-base region 5;

[0046] (2) Oxidize the PN structure obtained in step (1) to form SiO 2 layer mask layer, remove the SiO on the N side by photolithography 2 A mask layer, forming an n-type ionization-promoting layer 6 on the side of the n-base region through a diffusion process;

[0047] (3) Simultaneously oxidize the upper and lower surfaces of the above-mentioned silicon wafer to form SiO 2 Layer mask layer; through double-sided photolithography, the pattern of the photolithography plate is transferred to the two poles of the Si wafer; the SiO without photoresist protection is removed by etching 2 layer; then remove t...

Embodiment 1

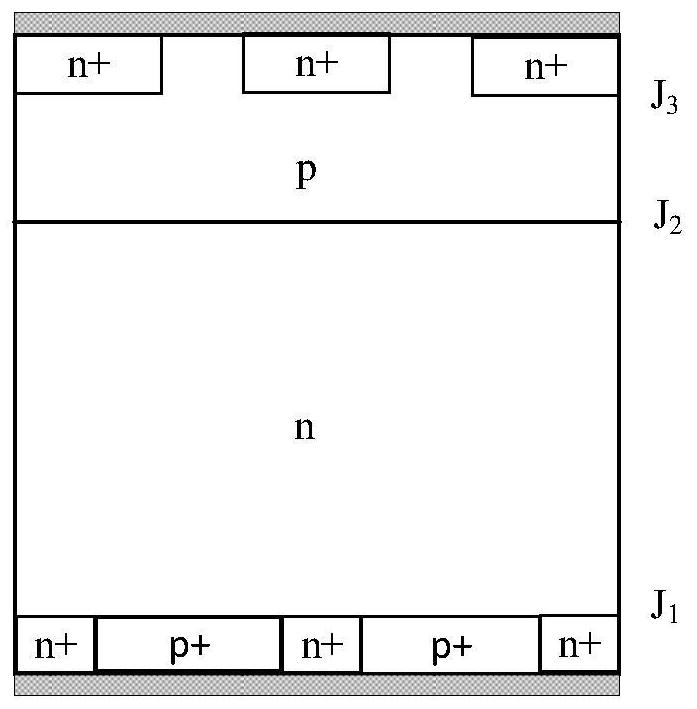

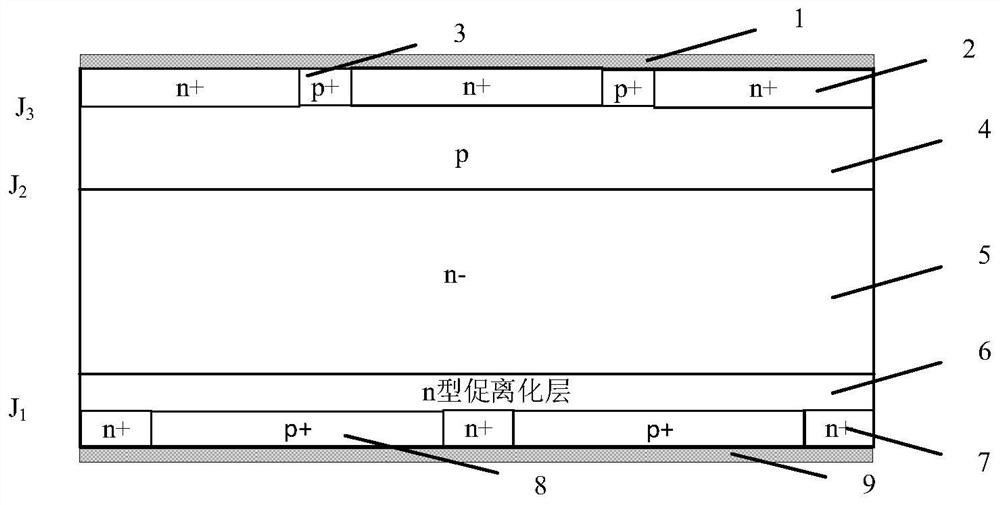

[0061] Such as image 3 As shown, a fast ionization device structure includes: metallized cathode 1, highly doped n+ region 2, highly doped p+ short circuit point 3 on the cathode side, p base region 4, n- base region 5, n-type ionization Layer 6, highly doped n+ short circuit point 7 on the anode side, highly doped p+ region 8, metallized anode 9. The highly doped p+ region 8 is located on the side of the metallized anode 9, and the highly doped n+ short circuit point 7 on the anode side is located between the highly doped p+ regions 8 on the side of the metallized anode 9; the n-type ionization layer 6 is located on the side of the highly doped p+ Layer 8, between the highly doped n+ short-circuit point 7 on the anode side and the n-base region 5, the p-base region 4 is located above the n-base region 5, and the highly-doped n+ region 2 is located between the p-base region 4 and the metallized cathode 1 Between, the highly doped p+ short circuit point 3 on the cathode side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com