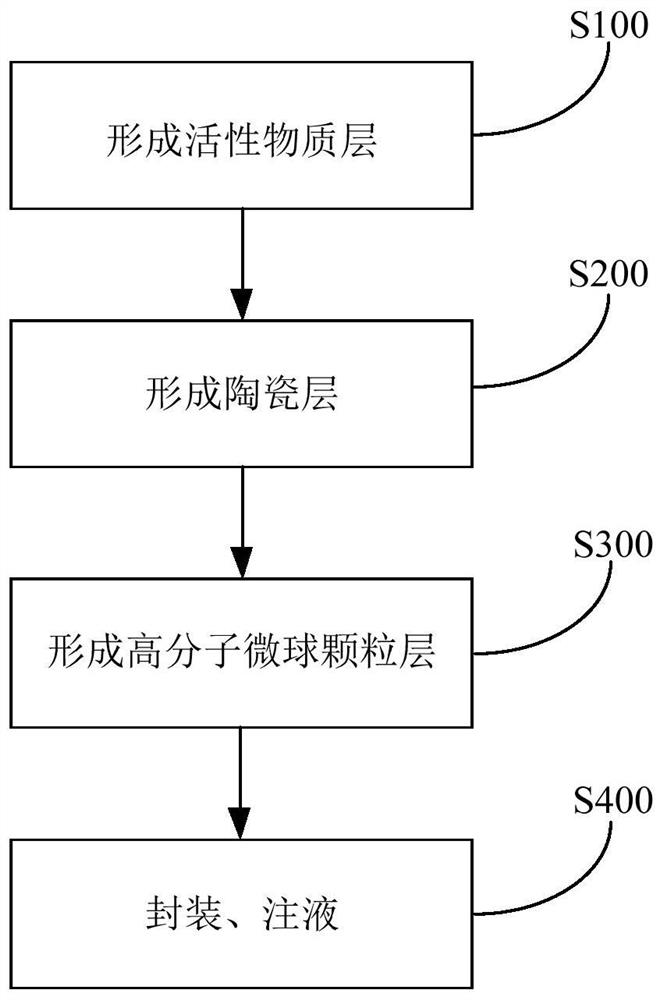

Lithium ion battery and preparation method thereof

A lithium-ion battery and polymer microsphere technology, which is applied in the manufacture of electrolyte storage batteries, batteries, secondary batteries, etc. The performance cannot be effectively guaranteed, so as to ensure the ionic conductivity, facilitate infiltration, and improve the overcharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of the positive electrode sheet: the positive electrode active material lithium nickel cobalt manganese oxide (NCM811), the positive electrode conductive agent conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) are NCM811:Super P:PVDF according to the weight ratio =96:1.5:2.5 for mixing, adding N-methylpyrrolidone (NMP), stirring evenly under the action of a vacuum mixer to obtain positive electrode slurry; uniformly coat the above positive electrode slurry on the surface of 12 μm aluminum foil, and dry at 110°C for 6h Afterwards, transfer to 120°C oven to dry for 1 hour, and then roll and roll it;

[0064] (2) Negative plate preparation: graphite powder, conductive carbon black SP, CMC, SBR are mixed according to the weight ratio of graphite: SP: CMC: SBR = 95: 1: 1.5: 2.5, add deionized water, in a vacuum mixer Stir evenly under the action to obtain negative electrode slurry; apply the above negative electrode slurry evenly on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com