A kind of method utilizing low-temperature plasma technology to prepare potassium ferrate

A technology of low-temperature plasma and potassium ferrate, applied in chemical instruments and methods, iron compounds, water/sludge/sewage treatment, etc., can solve problems such as danger, complicated preparation process, and low efficiency, and achieve strong adsorption, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

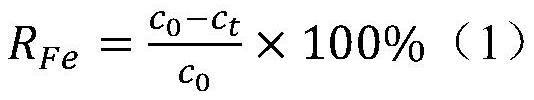

[0019] Effect of aqueous potassium hydroxide concentration on iron conversion and performance of prepared potassium perferrate

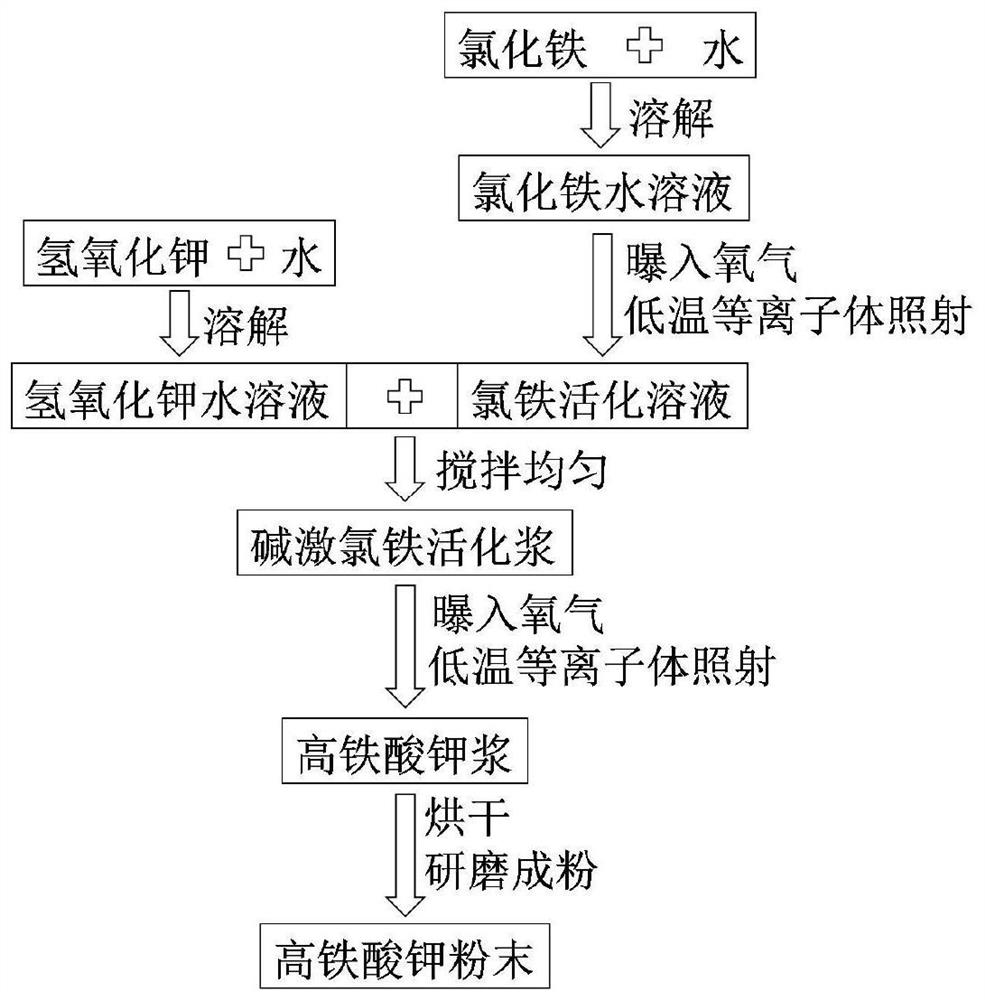

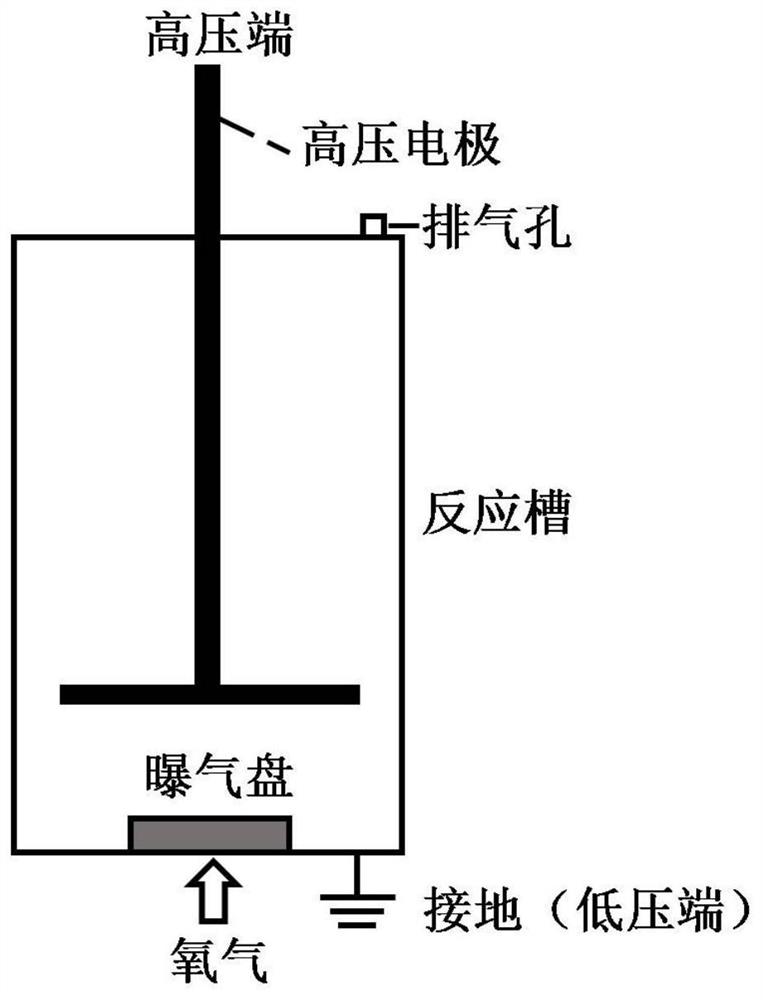

[0020] Preparation of potassium perferrate: as Figure 1 As shown, the ferric chloride is called dissolved in water, an aqueous solution of 1mol / L of ferric chloride is prepared, and the aqueous iron chloride solution is placed in a low-temperature plasma reaction cell ( Figure 2 ), the aeration plate at the bottom of the reaction tank is exposed to oxygen, and then the power supply is turned on for low-temperature plasma irradiation for 0.5 hours to obtain a ferric chloride activation solution, wherein the low-temperature plasma acting voltage is 5kV; call potassium hydroxide dissolved in water, respectively, prepare 0.25, 0.35, 0.45, 0.5, 2.5, 4.5, 5, 5.5, 6mol / L potassium hydroxide aqueous solution, according to the volume ratio of potassium hydroxide aqueous solution to ferroclorine activation solution is 1:1, the aqueous potassium hydroxide solution...

Embodiment 2

[0038] Effect of aqueous iron chloride concentration on iron conversion and the performance of prepared potassium perferrate

[0039] Preparation of potassium perferrate: weigh iron chloride dissolved in water, prepare 0.5, 0.7, 0.9, 1, 3, 5, 5.5, 6.5, 7.5mol / L aqueous iron chloride solution, the aqueous iron chloride solution is placed in a low-temperature plasma reaction cell, and the aeration plate at the bottom of the reaction tank is exposed to oxygen. Then turn on the power supply for low-temperature plasma irradiation for 1.5 hours to obtain ferrocrylate activation solution, of which the low-temperature plasma acting voltage is 27.5kV; call potassium hydroxide dissolved in water, prepare 4.5mol / L aqueous potassium hydroxide solution, according to the volume ratio of potassium hydroxide aqueous solution and ferroclorine activation solution is 2:1, the aqueous potassium hydroxide solution is mixed with ferric chloride activation solution, stirred evenly, and the alkali-excit...

Embodiment 3

[0048] The volume ratio of aqueous potassium hydroxide solution to ferrochlorinated solution affected the iron conversion rate and the performance of the prepared potassium perferrate

[0049]Preparation of potassium perferrate: weigh iron chloride dissolved in water, prepare 5mol / L aqueous iron chloride solution, place the aqueous iron chloride solution in a low-temperature plasma reaction tank, the aeration plate at the bottom of the reaction tank is exposed to oxygen, and then turn on the power supply for low-temperature plasma irradiation for 2.5 hours to obtain a ferroclorine activation solution, where the low-temperature plasma action voltage is 50kV; weigh potassium hydroxide dissolved in water, prepare 4.5mol / L potassium hydroxide aqueous solution, According to the volume ratio of potassium hydroxide aqueous solution to ferroclorine activation solution 0.5:1, 0.7:1, 0.9:1, 1:1, 2:1, 3:1, 3.2:1, 3.5:1, 4:1, respectively, the aqueous potassium hydroxide solution was mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com