UV LED photoinitiator and preparation method thereof

A technology of photoinitiator and compound, which is applied in the field of UVLED photoinitiator and its preparation, can solve the problems of increasing initiator and emission wavelength mismatch, and achieve the effects of increasing content, promoting surface curing, and good photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

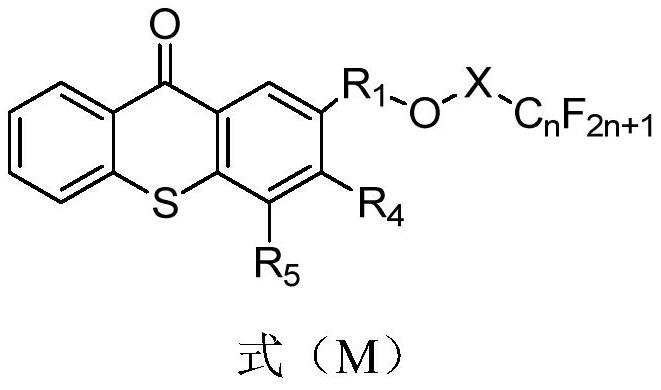

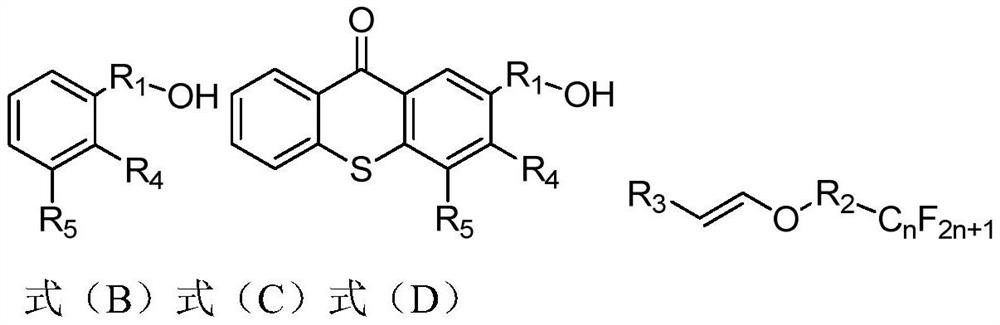

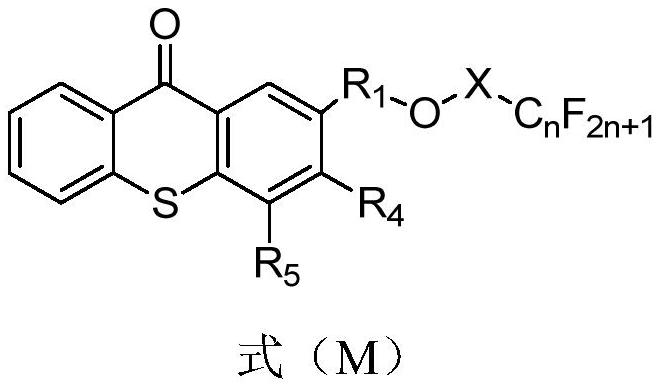

[0045] Specific description of the exclusive plan

[0046] The present embodiment provides a kind of UV LED photoinitiator, has formula (M 1 ) shown chemical structure, its preparation method is as follows.

[0047] synthetic route:

[0048]

[0049] Steps:

[0050] S1. Preparation formula (C 1 ) compound

[0051] 90.8g (0.59mol) of thiosalicylic acid was dissolved in 800mL of concentrated sulfuric acid, and 96.63g (0.89mol) of formula (B 1) compound, that is, hydroxymethylbenzene, and then heated to 80° C. for 2 h, and then placed at room temperature for 12 h. The reactant was slowly added to 2L of boiling water, cooled to room temperature, stirred for 1 h, and filtered to obtain a crude product. Thick product dioxane: acetone=3:1 mixed solvent carries out recrystallization, obtains light yellow product formula (C 1 ) compounds.

[0052] S2. Formula (M 1 ) Compound preparation

[0053] Under dark conditions, formula (C 1 ) compound (24.2g, 0.1mol) was dissolved ...

Embodiment 2

[0058] The present embodiment provides a kind of UV LED photoinitiator, has formula (M 2 ) shown chemical structure, its preparation method is as follows.

[0059] synthetic route:

[0060]

[0061] Steps:

[0062] S1. Preparation formula (C 2 ) compound

[0063] 90.8g (0.59mol) of thiosalicylic acid was dissolved in 1000mL of concentrated sulfuric acid, and 160.28g (1.18mol) of formula (B 2 ) compound, that is, m-methyl (hydroxyethyl) benzene, then heated up to 80° C. for 2 h, and left at room temperature for 12 h. The reactant was slowly added to 2.5 L of boiling water, cooled to room temperature, stirred for 1 h, and filtered to obtain a crude product. Thick product dioxane: acetone=3:1 mixed solvent carries out recrystallization, obtains light yellow product formula (C 2 ) compounds.

[0064] S2. Formula (M 2 ) Compound preparation

[0065] Under dark conditions, formula (C 2 ) compound (27.1g, 0.1mol) was dissolved in 240mL chloroform solution, adding formula...

Embodiment 3

[0070] The present embodiment provides a kind of UV LED photoinitiator, has formula (M 3 ) shown chemical structure, its preparation method is as follows.

[0071] synthetic route:

[0072]

[0073] Steps:

[0074] S1. Preparation formula (C 3 ) compound

[0075] 90.8g (0.59mol) of thiosalicylic acid was dissolved in 1000mL of concentrated sulfuric acid, and 177.12g (1.18mol) of formula (B 3 ) compound, then heated up to 80° C. for 2 h, and left at room temperature for 12 h. The reactant was slowly added to 2.5 L of boiling water, cooled to room temperature, stirred for 1 h, and filtered to obtain a crude product. Thick product dioxane: acetone=3:1 mixed solvent carries out recrystallization, obtains light yellow product formula (C 3 ) compounds.

[0076] S2. Formula (M 3 ) Compound preparation

[0077] Under dark conditions, formula (C 3 ) compound (28.4g, 0.1mol) was dissolved in 250mL chloroform solution, adding formula (D 3 ) compound (50.2g, 0.1mol), trifluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com