Polymer@two-dimensional material modified layered double hydroxide composite diaphragm material as well as preparation method and application thereof

A layered bimetallic, two-dimensional material technology, used in secondary batteries, electrochemical generators, electrical components, etc., to avoid agglomeration, improve battery performance, and improve sulfur loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

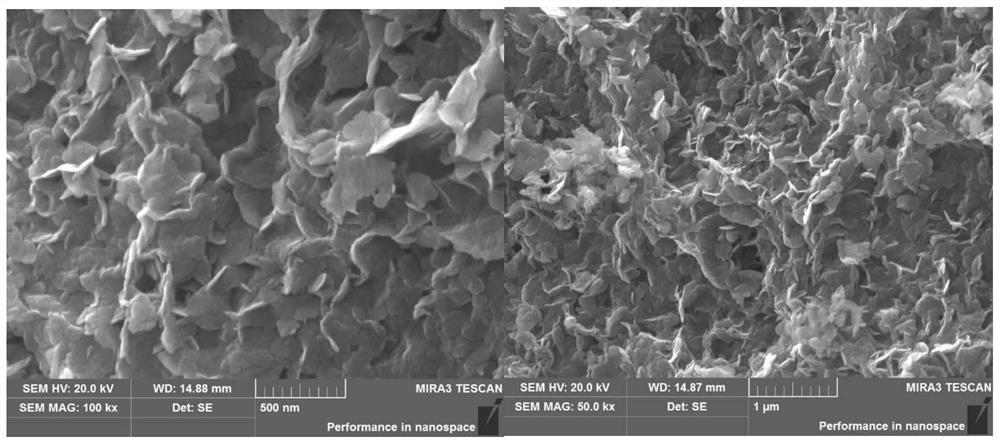

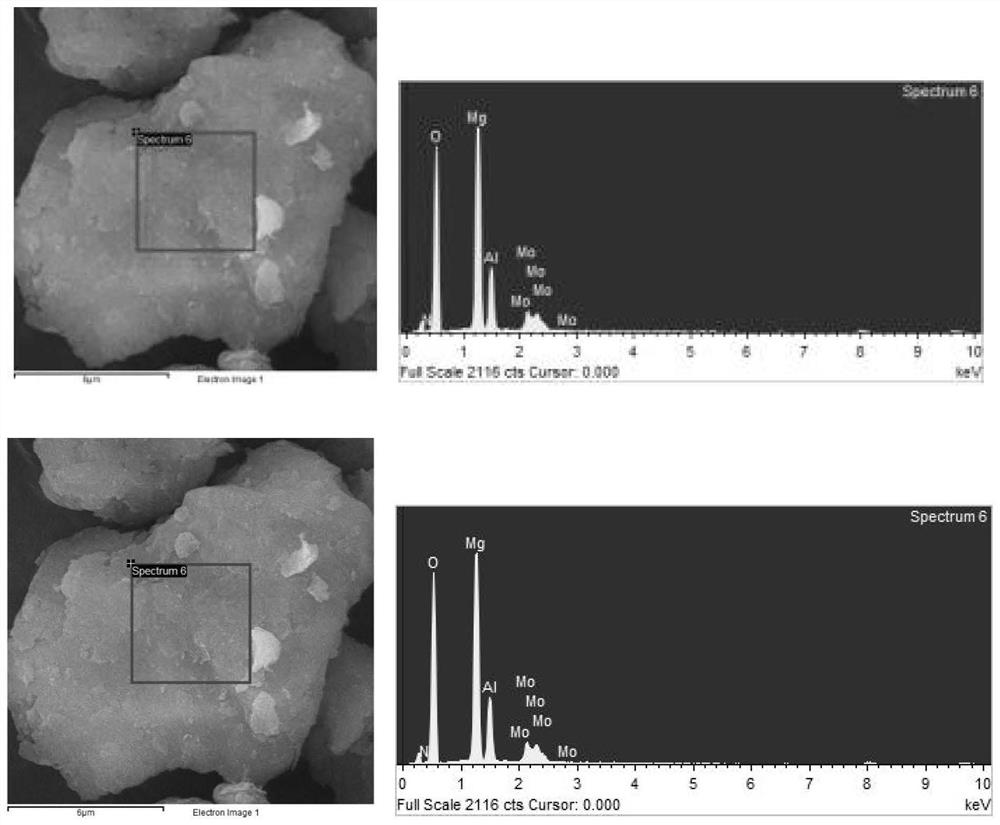

[0077] A kind of preparation of molybdenum diselenide / MgAl hydrotalcite composite material of the present invention, it specifically comprises the following steps:

[0078] (1) Add 0.03mol magnesium nitrate, 0.015mol aluminum nitrate, 0.01mol sodium molybdate and 0.1mol sodium hydroxide to 100mL water, stir and react at 45°C for 1h; then raise the temperature to 85°C for 6h; crystallize After the end, centrifuge and wash, filter after 30 minutes of ultrasonic field action, disperse the filter cake in 50mL water to make hydrotalcite prepolymer suspension;

[0079] (2) Take 0.632g of selenium powder and 10mL of hydrazine hydrate in a three-necked flask and stir for 30min, add 40mL of the above-mentioned hydrotalcite prepolymer suspension and ultrasonically disperse it, then place it in a high-pressure reactor, and heat up at a rate of 5°C / Raise the temperature to 200°C under the condition of 1 min, keep the temperature for 720 minutes (when 360 minutes, take out the ultrasonic ...

Embodiment 2

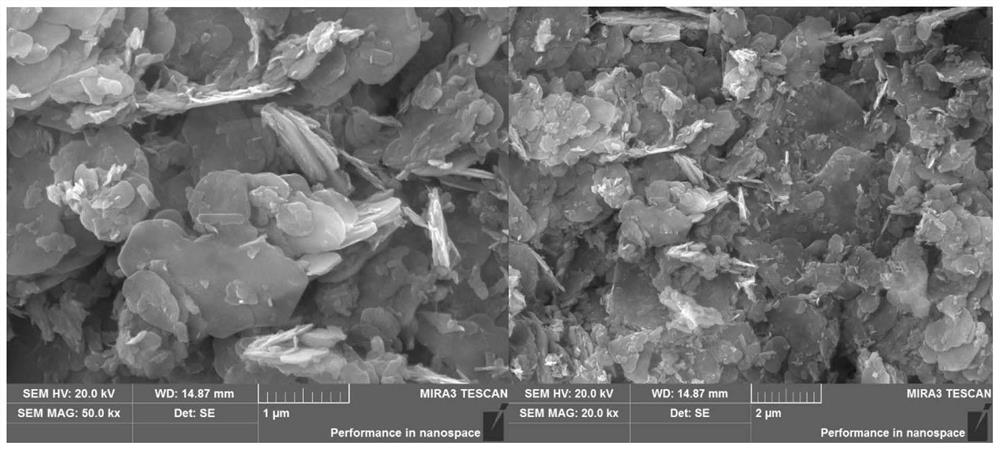

[0088] A molybdenum diselenide / CoAl hydrotalcite composite material prepared by the present invention is used as a preparation method for forming a Li-S battery diaphragm, and its specific steps are as follows:

[0089] (1) Add 0.03mol cobalt nitrate, 0.015mol aluminum nitrate, 0.01mol sodium molybdate and 0.1mol sodium hydroxide to 100mL water, stir at 45°C for 1h, then heat up to 85°C for 6h crystallization, and the crystallization is complete Finally, centrifugal washing, ultrasonic 30min, the filter cake is dispersed in 50mL water to make hydrotalcite prepolymer suspension;

[0090] (2) Take 0.632g of selenium powder and 10mL of hydrazine hydrate in a three-necked flask and stir for 30min, add 40mL of the above hydrotalcite prepolymer suspension and ultrasonically disperse it, then raise the temperature to 200°C at a heating rate of 5°C / min , insulated for different times (half of the incubating time, take out the ultrasonic for 20 minutes, continue to incubate after the e...

Embodiment 3

[0126] The preparation method is similar to that of Example 2, except that the hydrothermal reduction temperature of the CoAl hydrotalcite composite material is increased from 200° C. to 250° C.; the molybdenum diselenide / CoAl hydrotalcite composite material H is prepared.

[0127] The battery preparation and electrochemical performance test were carried out on the obtained material H, and the test conditions were the same as in Example 2.

[0128] The test results show that the initial discharge capacity is 1237mAh g at 0.1C -1 , compared to 1030mAh g of the PP separator alone -1 , boosted by 207mAh g -1 ;After 50 cycles, the PP@composite material H diaphragm battery maintains 567mAh g -1 Reversible capacity, compared to 470mAh g of PP diaphragm battery -1 increased.

[0129] From Comparative Example 5, Example 2 and Example 3, it can be seen that the hydrothermal reduction temperature of the composite material has a significant impact on the activity of the separator and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com