Aqueous electrolyte for improving reversibility of neutral zinc-manganese battery and preparation method of aqueous electrolyte

A water-based electrolyte, zinc-manganese battery technology, applied in water-based electrolytes, secondary batteries, circuits, etc., can solve the problems of electrolyte fluctuation, loss of capacity, accelerated dissolution, etc., to achieve a simple preparation method, improve reversibility, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A neutral organic / inorganic mixed aqueous electrolytic solution specifically includes an inorganic zinc salt, an organic complexing agent and an organic / inorganic acid-base stabilizer. The inorganic zinc salt is zinc sulfate of 1mol / L; the organic complexing agent is disodium edetate and urea, and the total concentration is 4mol / L; the organic / inorganic acid-base stabilizer is acetic acid of 0.1mol / L and 0.15mol / L of sodium acetate mixed solution. The specific order of adding each substance, that is, the configuration method of the electrolyte is: first configure the zinc sulfate basic electrolyte, then add the organic complexing agent edetate disodium and urea, and finally add an appropriate amount of mixed solution of acetic acid and sodium acetate , adjust the pH to 5.

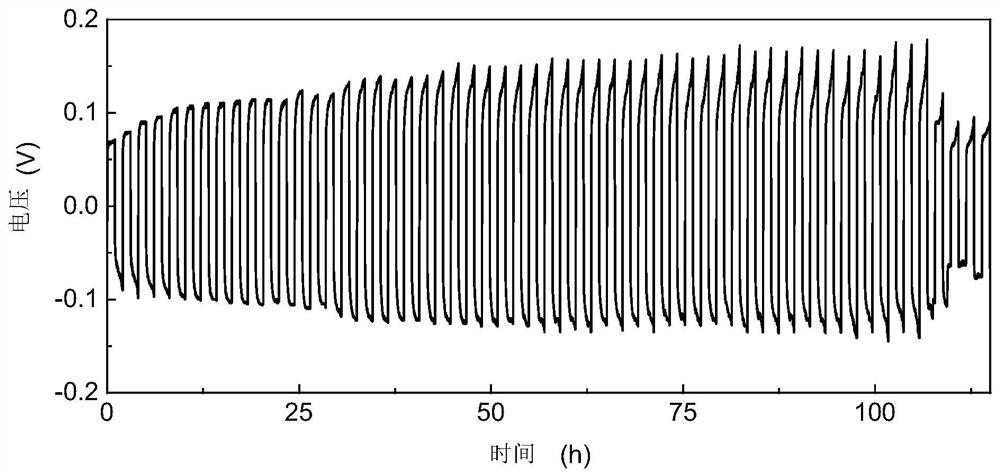

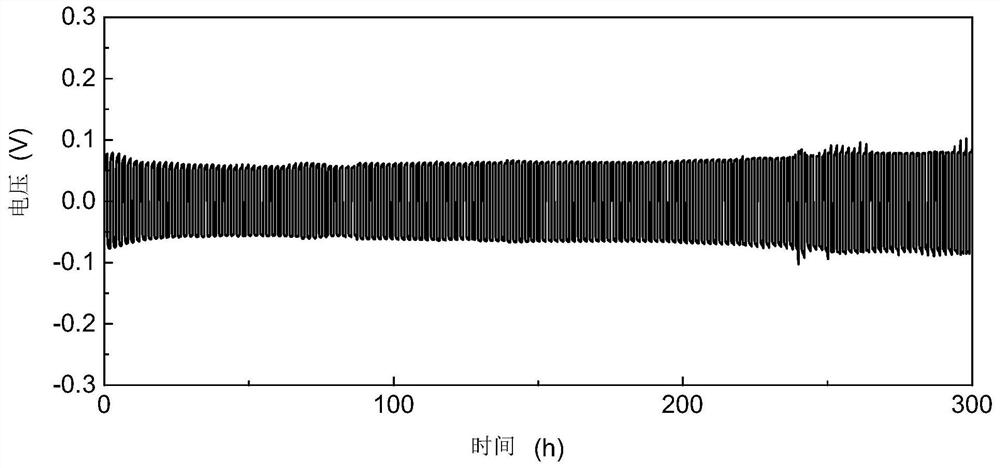

[0030] Such as figure 2 shown, compared to figure 1 Shown comparative example (traditional zinc sulfate electrolyte without any organic complexing agent and acid-base stabilizer), the zinc metal...

Embodiment 2

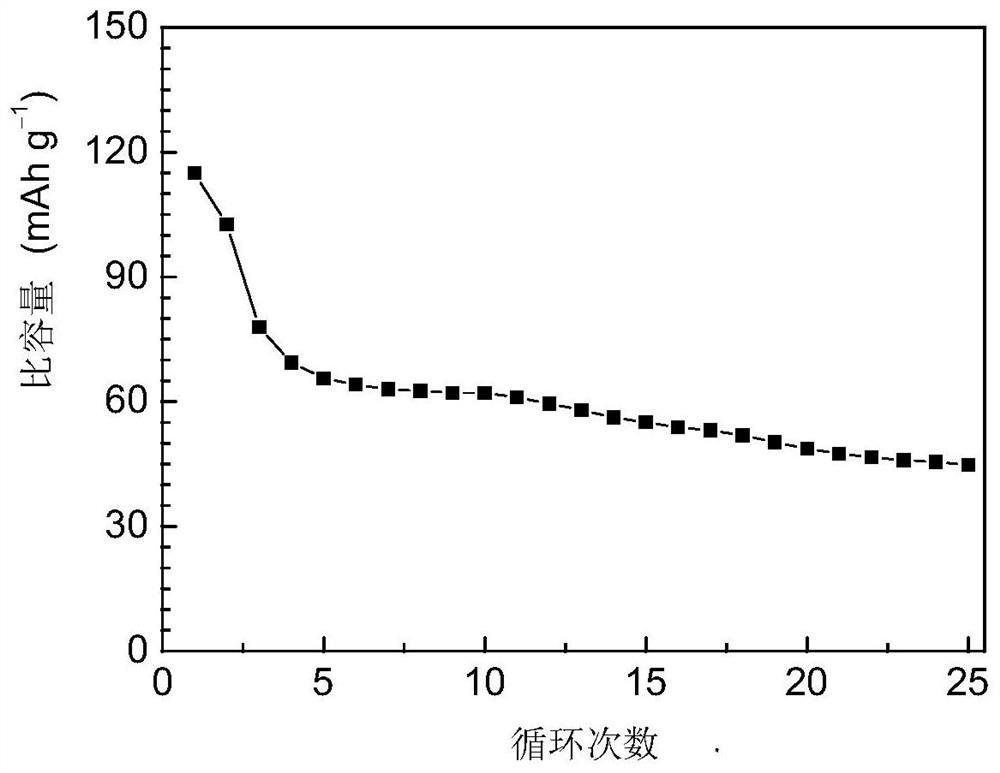

[0033] A neutral organic / inorganic mixed aqueous electrolytic solution specifically includes an inorganic zinc salt, an organic complexing agent and an organic / inorganic acid-base stabilizer. The inorganic zinc salt is 2mol / L zinc sulfate; the organic complexing agent is N-β-hydroxyethylethylenediaminetriacetic acid and urea, the total concentration is 8mol / L; the organic / inorganic acid-base stabilizer is 0.2mol / L Citric acid and 0.1mol / L sodium citrate mixed solution. The specific order of adding each substance, that is, the configuration method of the electrolyte is: the preparation method of the organic / inorganic mixed aqueous electrolyte is to configure the zinc sulfate basic electrolyte first, and then add the organic complexing agent ethylenediaminetetraacetic acid according to the complexing ratio Disodium and urea, and finally add an appropriate amount of citric acid and sodium citrate mixed solution to adjust the pH to 4.5. By assembling the zinc-manganese dioxide fu...

Embodiment 3

[0035] A neutral organic / inorganic mixed aqueous electrolytic solution specifically includes an inorganic zinc salt, an organic complexing agent and an organic / inorganic acid-base stabilizer. The inorganic zinc salt is 1mol / L zinc acetate, the organic complexing agent is 1mol / L disodium edetate, and the organic / inorganic acid-base stabilizer is a mixed solution of 0.35mol / L acetic acid and 0.05mol / L sodium acetate.

[0036]The specific order of adding each substance, that is, the configuration method of the electrolyte is: first configure the zinc acetate basic electrolyte, then add the organic complexing agent disodium edetate according to the complexation ratio, and finally add an appropriate amount of acetic acid and sodium acetate Mix the solution and adjust the pH to 4.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com