Freezing balloon catheter with excellent biocompatibility

A biocompatible, balloon catheter technology, used in catheters, cooling surgical instruments, and parts of surgical instruments, etc., can solve the problems of cell tissue destruction, slow cooling rate at the pulmonary vein port, and inability to cure atrial fibrillation. The effect of improving hydrophilicity and improving protein adsorption resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

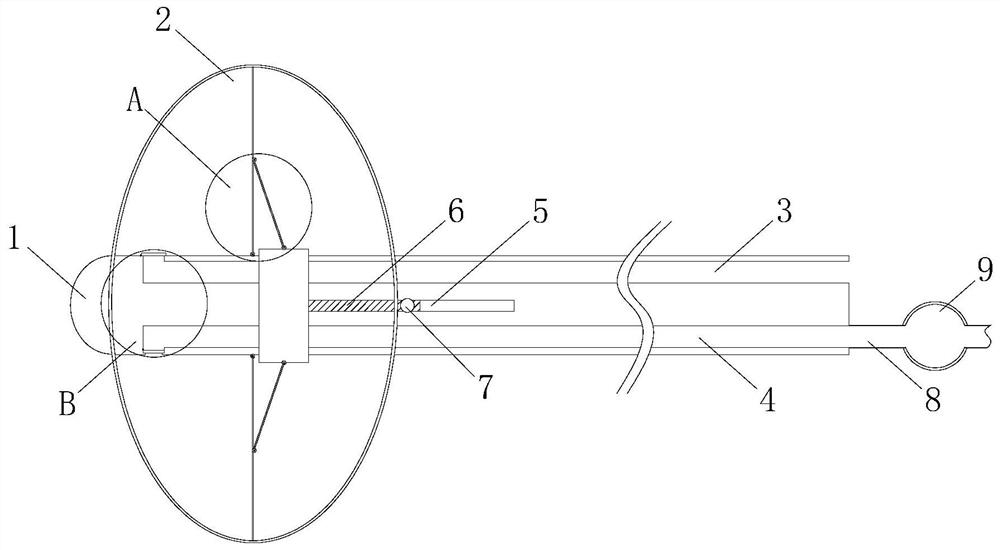

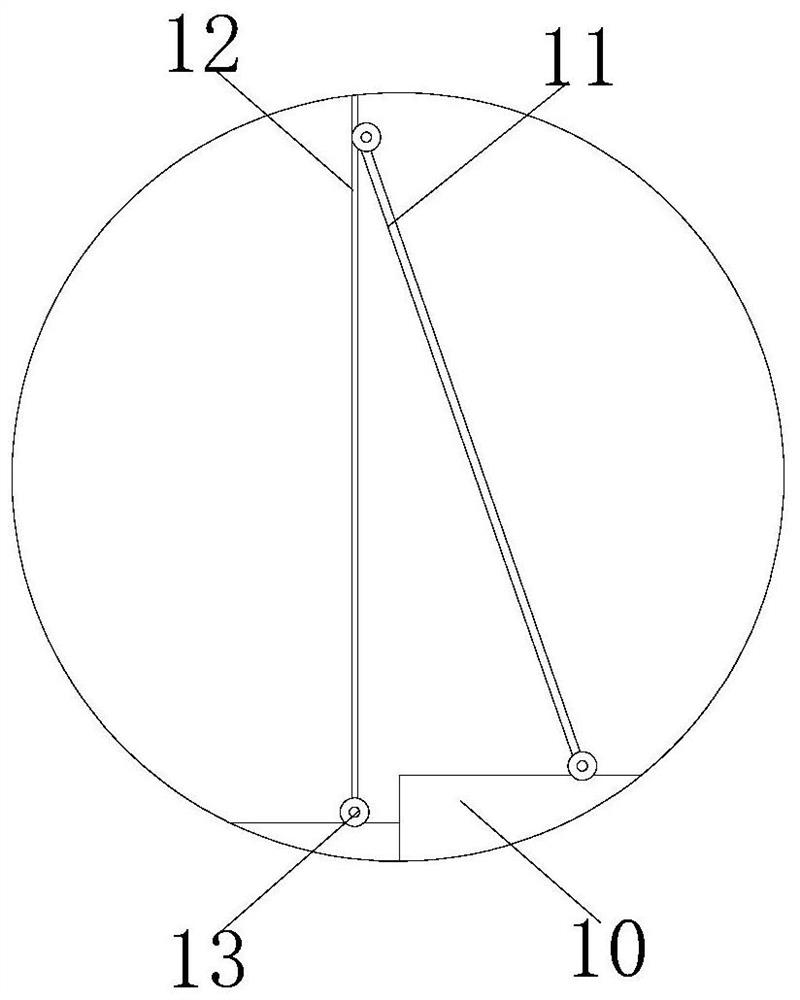

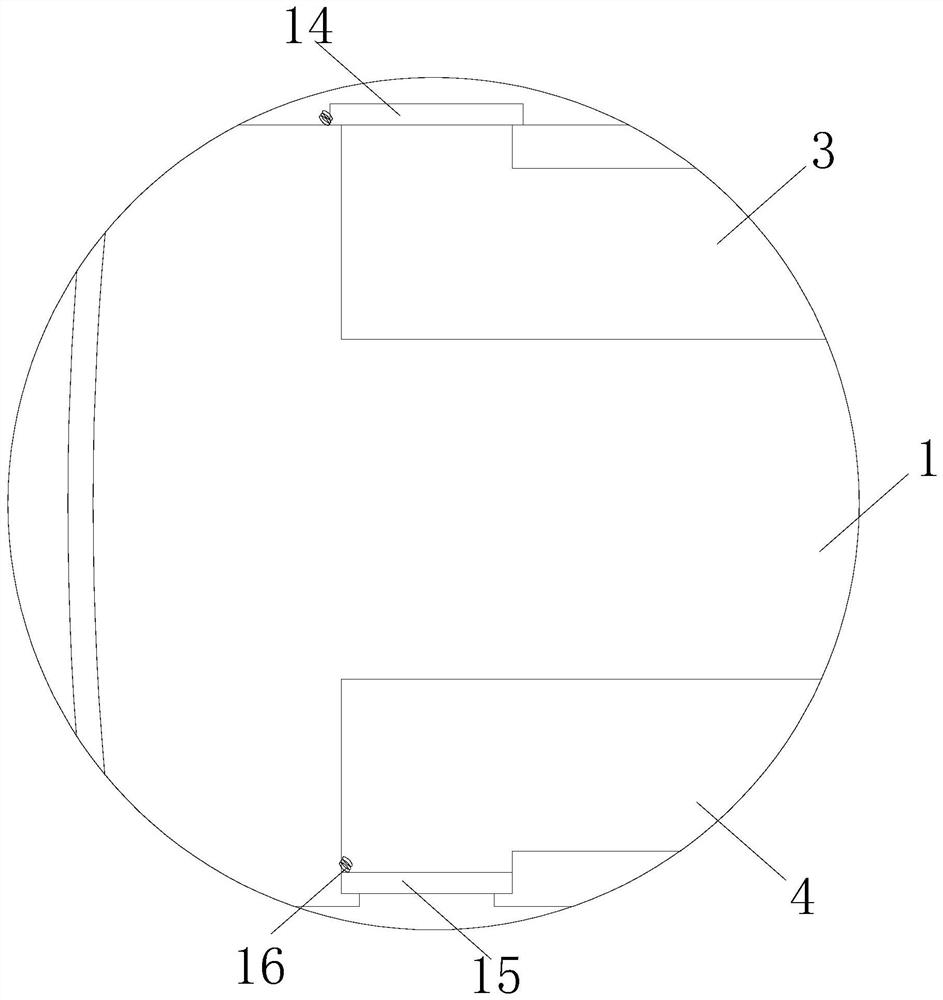

[0055] see Figure 1-3 , a cryoballoon catheter with excellent biocompatibility, including a catheter 1 and a rubber suction ball 9, the left side of the outer ring of the catheter 1 is sheathed with a balloon 2, and both the catheter 1 and the balloon 2 are made of PET material , the top of the right side of the catheter 1 is provided with an infusion channel 3, the liquid outlet of the infusion channel 3 is connected with the inner cavity of the balloon 2, the liquid inlet of the infusion channel 3 is connected with the liquid outlet of the refrigeration equipment, and the infusion channel 3 The liquid outlet is provided with a first baffle 14, a spring 16 is connected between the left side of the first baffle 14 and the top of the conduit 1, the bottom of the right side of the conduit 1 is provided with an exhaust passage 4, and the exhaust passage 4 The air inlet is connected with the inner cavity of the balloon 2, the outer diameter of the first blocking plate 14 is great...

Embodiment 2

[0057] A cryoballoon catheter with excellent biocompatibility. The difference from Example 1 is that the PET material has been modified, including the following raw materials in parts by weight: 5 parts of PET, 3 parts of polyethylene glycol, and 1 part of neutral amino acid , 2 parts of dodecyl dimethyl benzyl ammonium bromide (CAS No.: 7281-04-1); the polyethylene glycol is PEG-400, PEG-1000, PEG-400, PEG-1000 mass ratio The neutral amino acid is 1:2; the neutral amino acid is glycine and L-leucine, and the mass ratio of glycine and L-leucine is 4:1; it includes the following steps:

[0058] (1) PET passes through the low-temperature plasma processor, the operation steps are: connect the plasma device, set the plasma gas flow rate as: NH 3 3 sccm, O 2 2sccm, vacuum degree 20Pa, temperature 25℃, treatment 100s.

[0059] (2) Dissolve 3 parts of polyethylene glycol and 1 part of neutral amino acid in 10 parts of deionized water, stir evenly, put the PET material obtained in...

Embodiment 3

[0066] A cryoballoon catheter with excellent biocompatibility, the difference from Example 1 is that the PET material is modified, including the following raw materials in parts by weight: 5 parts of PET, 5 parts of polyethylene glycol, and 1 part of neutral amino acid , 2 parts of dodecyl dimethyl benzyl ammonium chloride (CAS No.: 139-07-1); the polyethylene glycol is PEG-400, PEG-1000, PEG-400, PEG-1000 mass ratio The neutral amino acid is 1:3; the neutral amino acid is glycine and L-leucine, and the mass ratio of glycine and L-leucine is 5:1; it includes the following steps:

[0067] (1) PET passes through the low-temperature plasma processor, the operation steps are: connect the plasma device, set the plasma gas flow rate as: NH 3 3 sccm, O 2 1sccm, vacuum degree 20Pa, temperature 25℃, treatment 100s.

[0068] (2) Dissolve 5 parts of polyethylene glycol and 1 part of neutral amino acid in 10 parts of deionized water, stir evenly, put the PET material obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com