Application of phenolic resin coating treatment technology to preparation of powder metallurgy material with ball milling method

A phenolic resin, processing technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as poor sintering compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

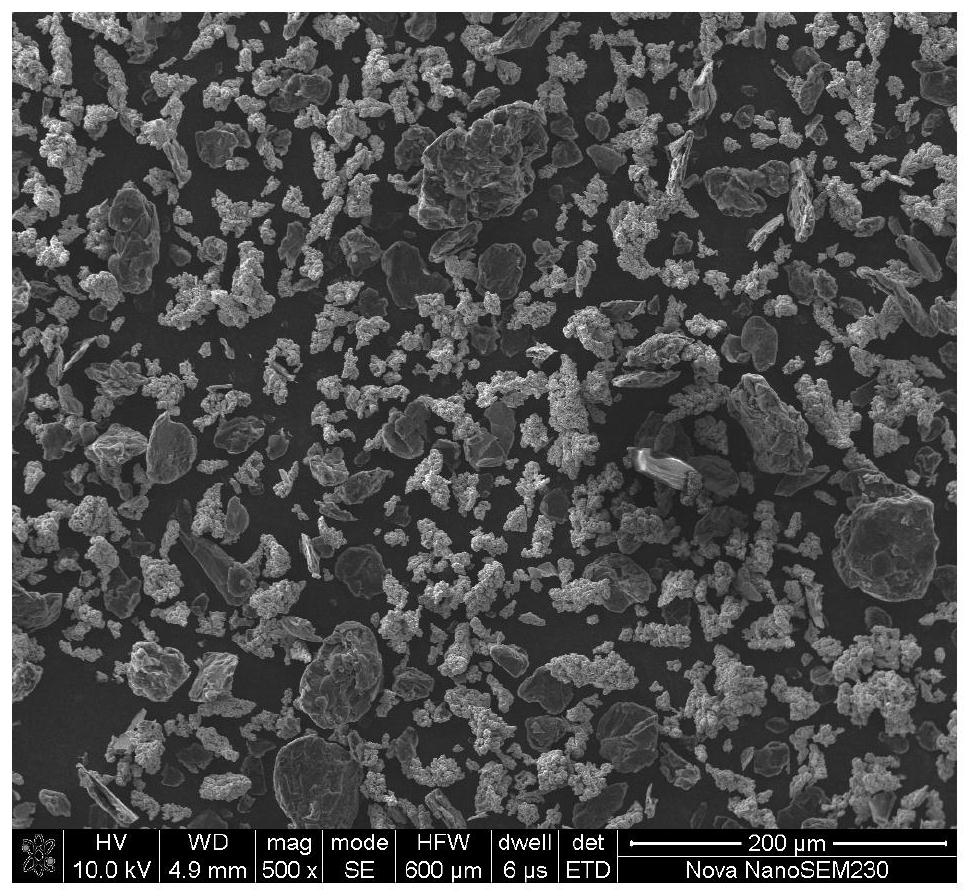

[0054] In Example 1, graphite flakes coated with phenolic resin and electrolytic copper powder were added to the ball milling equipment for high-energy ball milling. The particle size of the selected electrolytic copper powder is 150 μm (its hardness is 38 HV), and the particle size of flake graphite is 100 μm. Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution, then impregnate the graphite flakes in an 80°C phenolic resin alcohol saturated solution for 2h, and then dry at 200°C for 10min. Then ball mill with electrolytic copper powder, the volume ratio of electrolytic copper powder and flake graphite is 5:1, the ball milling speed is 200 rpm, the ball milling time is 0.5h, the ball milling ball is stainless steel ball, the ball diameter is 3mm~10mm (ball milling ball The mass ratio of diameter 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1), the sum of the mass of flake graphite and electrolytic copper pow...

Embodiment 2

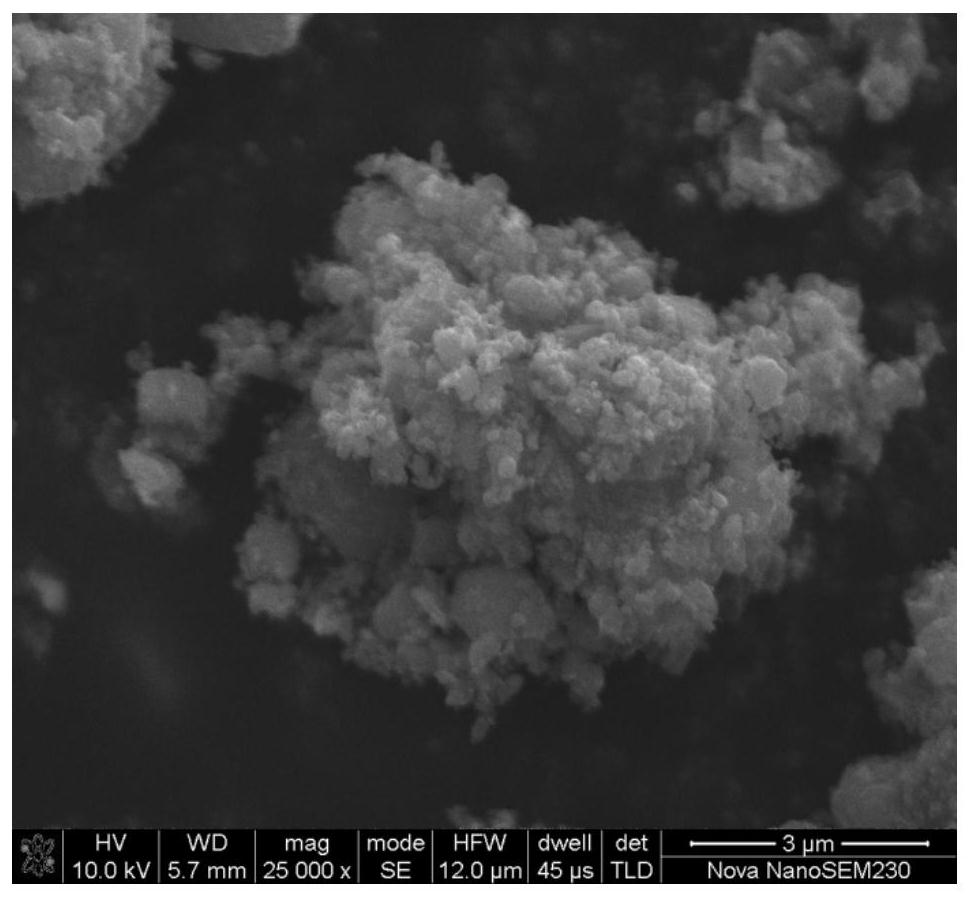

[0058]In Example 2, the SiC whiskers coated with phenolic resin and electrolytic copper powder were added to the ball milling equipment for high energy ball milling. The particle size of the selected electrolytic copper powder is 150 μm (its hardness is 38 HV), and the SiC whisker has a diameter of 2 μm and a length of 200 μm. Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution, then impregnate the SiC whiskers in the phenolic resin alcohol saturated solution at 80°C for 2h, and then dry it at 100°C for 2h. Then ball mill with electrolytic copper powder, the volume ratio of electrolytic copper powder and SiC whisker is 8:1, the ball milling speed is 220 rpm, the ball milling time is 1h, the ball milling ball is stainless steel ball, the ball diameter is 3mm~10mm (ball milling ball The mass ratio of diameter 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1), the sum of the mass of SiC whisker and electrolytic c...

Embodiment 3

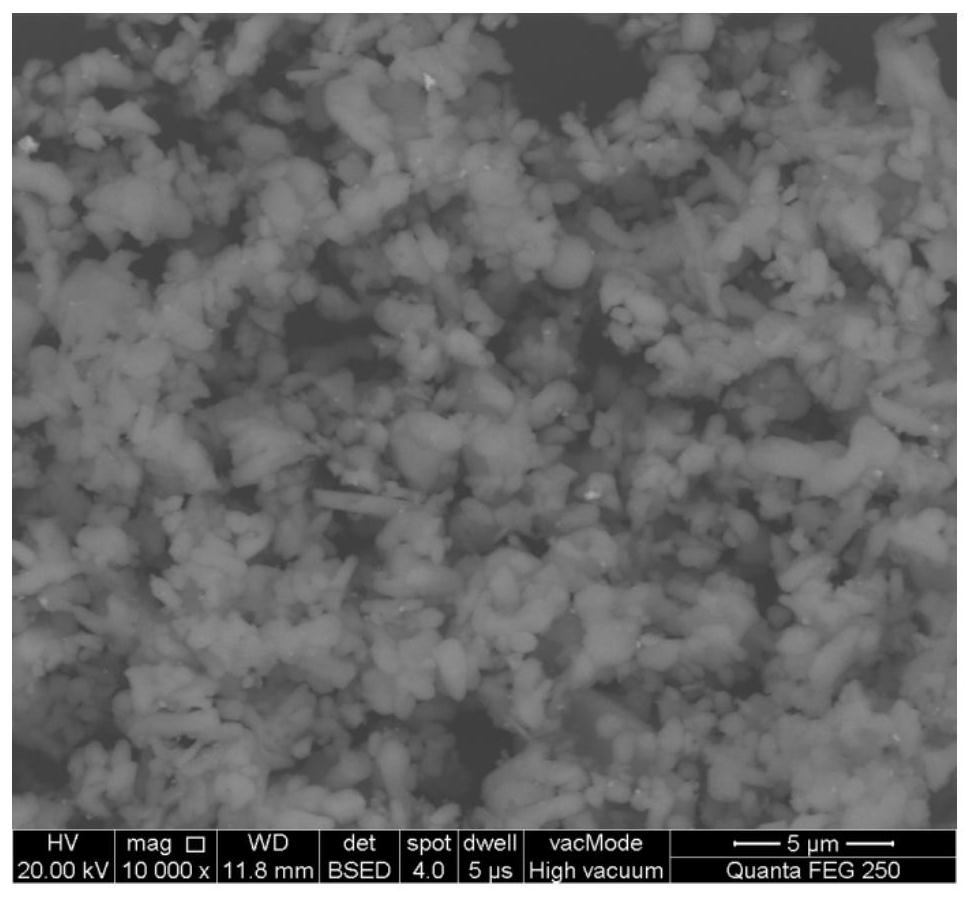

[0064] Present embodiment 3 is coated with ZrO with phenolic resin 2 The particles are fed into the ball milling equipment together with the electrolytic nickel powder for high energy ball milling. The particle size of the selected electrolytic nickel powder is 100μm (the hardness of the nickel powder is 50HV), ZrO 2 The particle size of the particles was 5 μm. Dissolve the prepared phenolic resin in an organic solvent to obtain a saturated solution of phenolic resin alcohol, and then ZrO 2 The particles were impregnated in phenolic resin alcohol saturated solution at 80°C for 2h, and then dried at 100°C for 2h. Then ball mill with electrolytic nickel powder, electrolytic nickel powder and ZrO 2 The volume ratio of the particles is 10:1, the milling speed is 220 rpm, the milling time is 1h, the milling balls are stainless steel balls, and the ball diameter is 3mm to 10mm (ball milling ball diameters are 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, The mass ratio of 9mm is 4:8:11:20:12:8:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com