Preparation method of solid film, quantum dot light-emitting device and preparation method

A solid-state film and device technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as poor electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a solid-state film and a quantum dot light-emitting device, and the solid-state film is mainly prepared through the following steps:

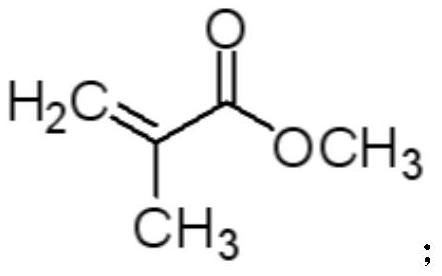

[0059] Mix 0.5mol methyl methacrylate with 100g ZnO nanoparticles, mix evenly, add tetramethylammonium hydroxide solution dropwise to the mixed solution until the solution is clear; form a film on a clean glass substrate by spin coating, The film was then dried at room temperature to obtain a solid film.

[0060] Quantum dot light-emitting devices are mainly prepared through the following steps:

[0061] A hole transport layer, a quantum dot luminescent layer, an electron transport layer, and a cathode are sequentially prepared on a clean glass substrate (containing an anode); wherein, the electron transport layer adopts the above-mentioned preparation method of a solid film.

Embodiment 2

[0063] This embodiment provides a solid-state film and a quantum dot light-emitting device, and the solid-state film is mainly prepared through the following steps:

[0064] Take 0.8mol methyl methacrylate and 100g of TiO 2 The nanoparticles are mixed, and after uniform mixing, ammonia water is added dropwise to the mixed solution until the solution is clear; a film is formed on a clean glass substrate by coating, and then the film is dried at room temperature to obtain a solid film.

[0065] Quantum dot light-emitting devices are mainly prepared through the following steps:

[0066] A hole transport layer, a quantum dot luminescent layer, an electron transport layer, and a cathode are sequentially prepared on a clean glass substrate (containing an anode); wherein, the electron transport layer adopts the above-mentioned preparation method of a solid film.

Embodiment 3

[0068] This embodiment provides a solid-state film and a quantum dot light-emitting device, and the solid-state film is mainly prepared through the following steps:

[0069] Take 0.8mol methyl methacrylate and 100g of TiO 2 The nanoparticles are mixed, and after uniform mixing, ammonia water is added dropwise to the mixed solution until the solution is clear; a film is formed on a clean glass substrate by spin coating, and then the film is dried at room temperature to obtain a solid film.

[0070] Quantum dot light-emitting devices are mainly prepared through the following steps:

[0071] A hole transport layer, a quantum dot luminescent layer, an electron transport layer, and a cathode are sequentially prepared on a clean glass substrate (containing an anode); wherein, the electron transport layer adopts the above-mentioned preparation method of a solid film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com