Bentonite/sulfur composite material as well as preparation method and application thereof

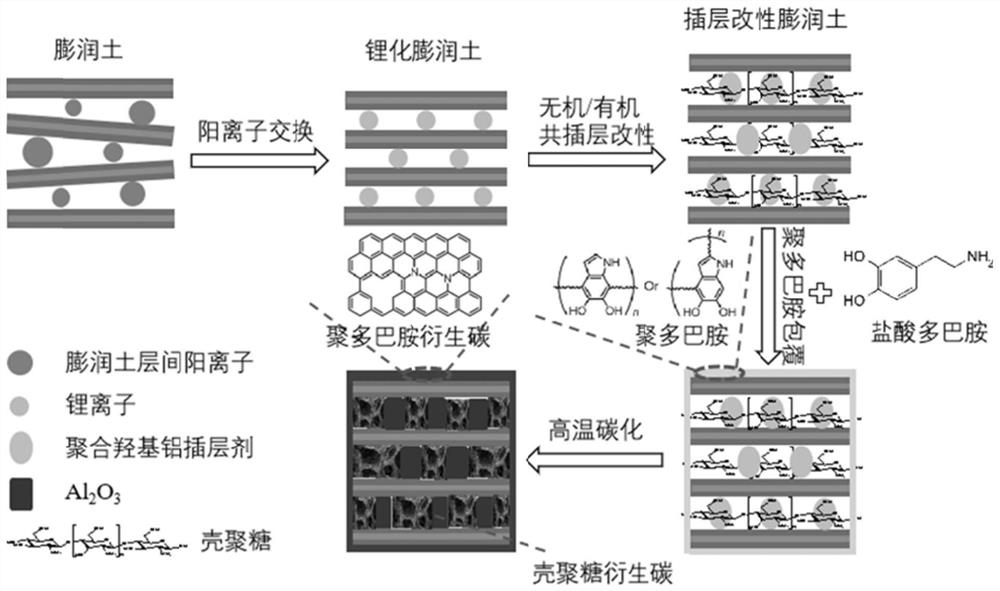

A technology of composite materials and bentonite, applied in the direction of active material electrodes, electrical components, battery electrodes, etc., can solve the problems of poor electrical conductivity and narrow ion transmission channels, and achieve the goal of improving electrical conductivity, efficient ion channels, and improving electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 5g of bentonite to 50mL of 1M LiCl aqueous solution, stir at 60°C for 2h, filter, and wash the filter cake repeatedly with deionized water until no chloride ions exist in the washing liquid.

[0041] Add the washed filter cake to 500mL deionized water, stir for 1h to obtain a suspension with a mass fraction of 1wt%; heat the above suspension to 60°C, 3+ The ratio of / g bentonite, slowly add the polymerized hydroxyaluminum ion intercalation agent, stir while adding, continue to be 1:1 according to the ratio of chitosan and bentonite mass ratio, slowly add the concentration of 1wt% to the suspension Chitosan acetic acid solution (concentration of acetic acid is 1wt%), stir while adding, continue to stir at 60 ℃ for 6h after the acetic acid solution of chitosan is added, then stand and age at room temperature for 24h, filter, use deionized The filter cake was repeatedly washed with water until the washing solution became neutral, and then dried at 105° C. to obtain pol...

Embodiment 2

[0048] Compared with Example 1, the main difference is that at first the natural bentonite is subjected to sodium treatment.

[0049] Add 5g of bentonite to 50mL of 1M NaCl aqueous solution, stir at 60°C for 2h, filter, and wash the filter cake repeatedly with deionized water until no chloride ions exist in the washing liquid.

[0050] Add the washed filter cake to 500mL deionized water, stir for 1h to obtain a suspension with a mass fraction of 1wt%; heat the above suspension to 60°C, 3+ The ratio of / g bentonite, slowly add the polymerized hydroxyaluminum ion intercalation agent, stir while adding, continue to be 1:1 according to the ratio of chitosan and bentonite mass ratio, slowly add the concentration of 1wt% to the suspension Chitosan acetic acid solution (concentration of acetic acid is 1wt%), stir while adding, continue to stir at 60 ℃ for 6h after the acetic acid solution of chitosan is added, then stand and age at room temperature for 24h, filter, use deionized The...

Embodiment 3

[0056] Compared with Example 1, the main difference is that polymeric hydroxyl iron ions are used as the inorganic intercalation modifier.

[0057] Add 5g of bentonite to 50mL of 1M LiCl aqueous solution, stir at 60°C for 2h, filter, and wash the filter cake repeatedly with deionized water until no chloride ions exist in the washing liquid.

[0058] Add the washed filter cake to 500mL deionized water, stir for 1h to obtain a suspension with a mass fraction of 1wt%; heat the above suspension to 60°C, 3+ The ratio of / g bentonite, slowly add the polymeric hydroxyl iron ion intercalation agent, stir while adding, continue to be 1:1 according to the ratio of chitosan and bentonite mass ratio, slowly add the concentration of 1wt% to the suspension Chitosan acetic acid solution (concentration of acetic acid is 1wt%), stir while adding, continue to stir at 60 ℃ for 6h after the acetic acid solution of chitosan is added, then stand and age at room temperature for 24h, filter, use deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com