Carbon-coated two-dimensional transition metal phosphide and preparation method and application thereof

A transition metal and transition metal salt technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Improved electrocatalytic hydrogen evolution performance, simple equipment, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

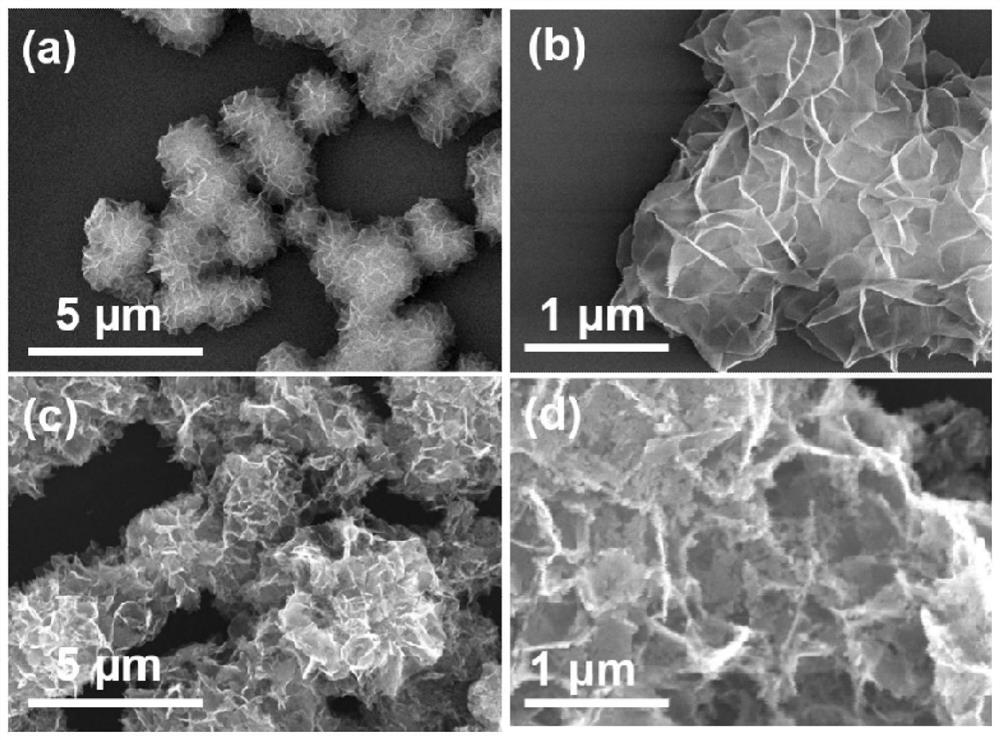

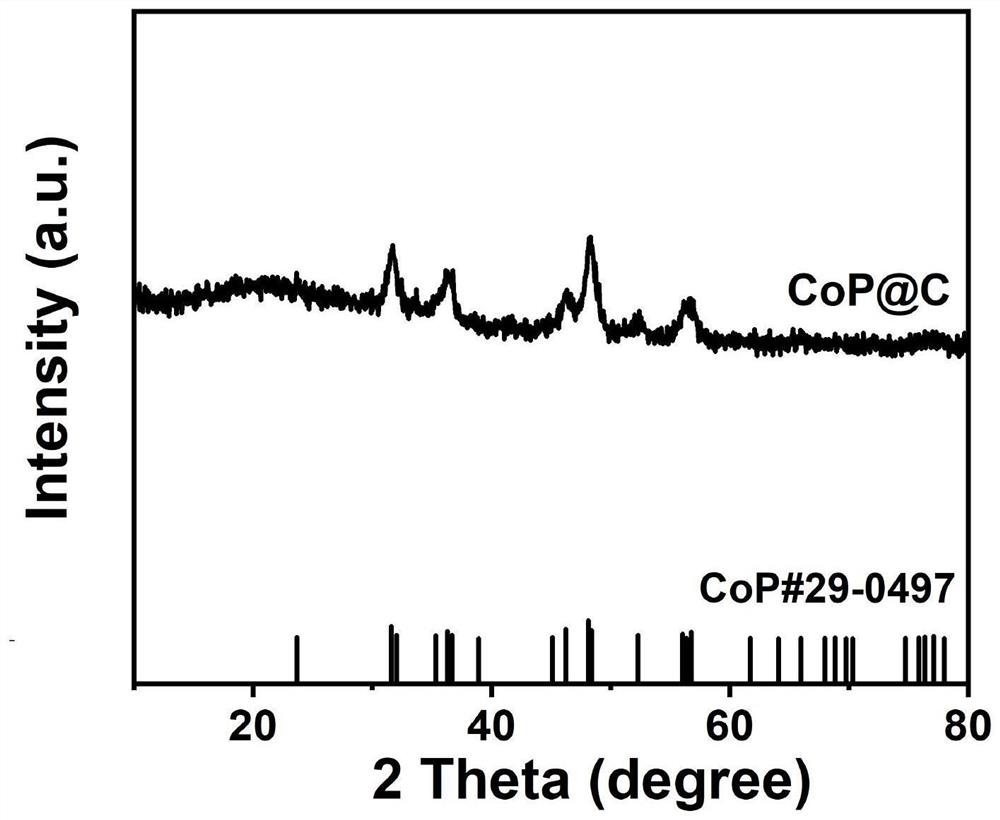

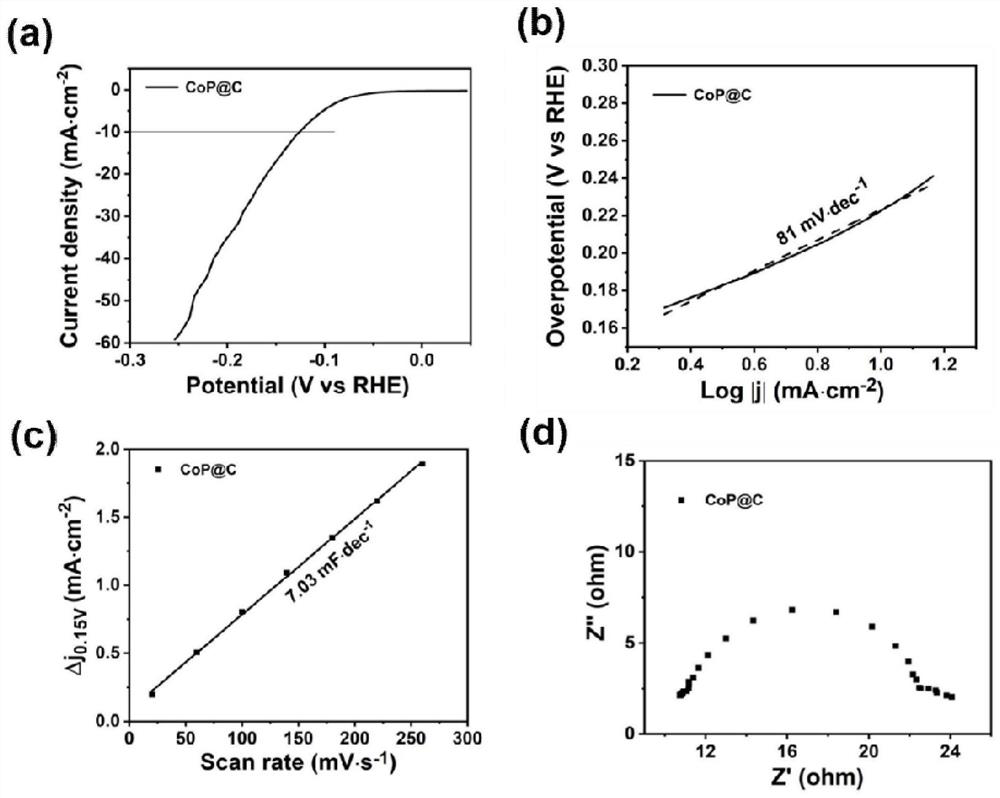

[0034] Example 1: Preparation of carbon-coated cobalt phosphide two-dimensional nanosheets and their hydrogen evolution performance

[0035] (1) Preparation of carbon-coated cobalt phosphide two-dimensional nanosheets

[0036] Weigh 3 mmol of cobalt nitrate hexahydrate and dissolve in 30 mL of methanol solution, and ultrasonically dissolve to obtain solution A; weigh 3 mmol of dimethylimidazole and dissolve in 10 mL of methanol solution, and ultrasonically dissolve to obtain solution B. Under the condition of magnetic stirring, the solution A and the solution B were rapidly mixed, transferred to a water bath environment at 35° C., and kept at constant temperature for 24 hours. Then take it out and centrifuge with absolute ethanol to remove the supernatant to leave a solid powder, and vacuum dry to obtain a solid powder containing cobalt salt. The prepared powder is placed in a small porcelain boat, and the outer layer is a large porcelain boat that can wrap up and down the in...

Embodiment 2

[0042] Example 2: Preparation of carbon-coated nickel phosphide two-dimensional nanosheets and their hydrogen evolution performance

[0043] (1) Preparation of carbon-coated nickel phosphide two-dimensional nanosheets

[0044] Weigh 3mmol of nickel sulfate powder and dissolve in 30mL of dimethylformamide solution, ultrasonically dissolve to obtain solution A, weigh 3mmol of 1,4-phthalic acid and dissolve in 10mL of dimethylformamide solution, and ultrasonically dissolve to obtain solution B. Under the condition of magnetic stirring, the solution A and the solution B were mixed rapidly, and then transferred to a water bath environment at 35° C., and stood still for 24 hours. Then take it out and centrifuge with absolute ethanol to remove the supernatant to leave a solid powder, and dry it in vacuum to obtain a nickel-containing salt powder. The prepared nickel salt powder is placed in a small porcelain boat, and the outer layer is a large porcelain boat that can wrap the inner...

Embodiment 3

[0049] Example 3: Preparation of carbon-coated cobalt-nickel phosphide bimetallic two-dimensional nanosheets and their hydrogen evolution performance

[0050] (1) Preparation of carbon-coated cobalt-nickel phosphide bimetallic two-dimensional nanosheets

[0051] Weigh 0.6 mmol of cobalt nitrate hexahydrate and 2.4 mmol of nickel nitrate hexahydrate and dissolve in 30 mL of ethanol solution, and dissolve by ultrasonic to obtain solution A; weigh 3 mmol of dimethylimidazole and dissolve in 10 mL of ethanol solution, and dissolve by ultrasonic to obtain solution B. Under the condition of magnetic stirring, the solution A and the solution B were mixed rapidly, and then transferred to a water bath environment at 35° C., and stood still for 24 hours. Then take out and centrifuge with absolute ethanol to remove the supernatant to leave a solid powder, and vacuum dry to obtain the powder containing nickel-cobalt double metal salt. Place the prepared nickel-cobalt double metal salt po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com