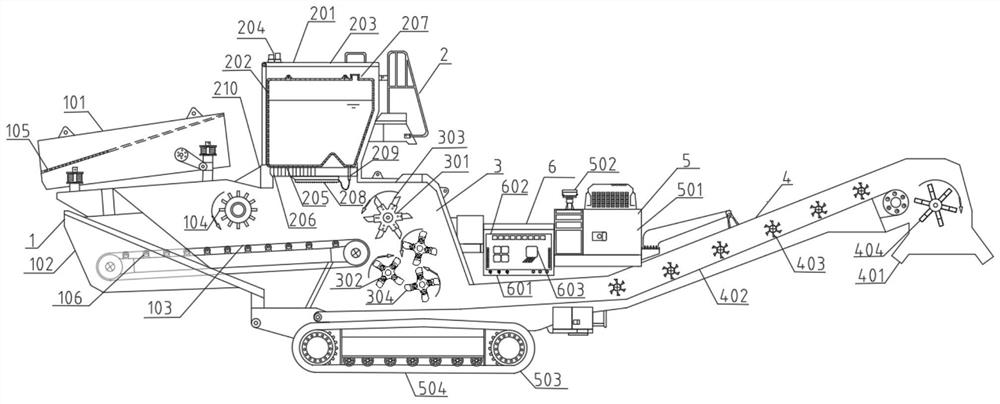

Crushing and uniform mixing integrated intelligent remediation equipment for soil remediation

A soil remediation and intelligent remediation technology, which is applied in the restoration of contaminated soil, mixers, chemical instruments and methods, etc., can solve the problems of poor mobility and operation stability, inaccurate measurement accuracy, and low degree of intelligence. Improve the mixing degree, avoid secondary pollution, and have a strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

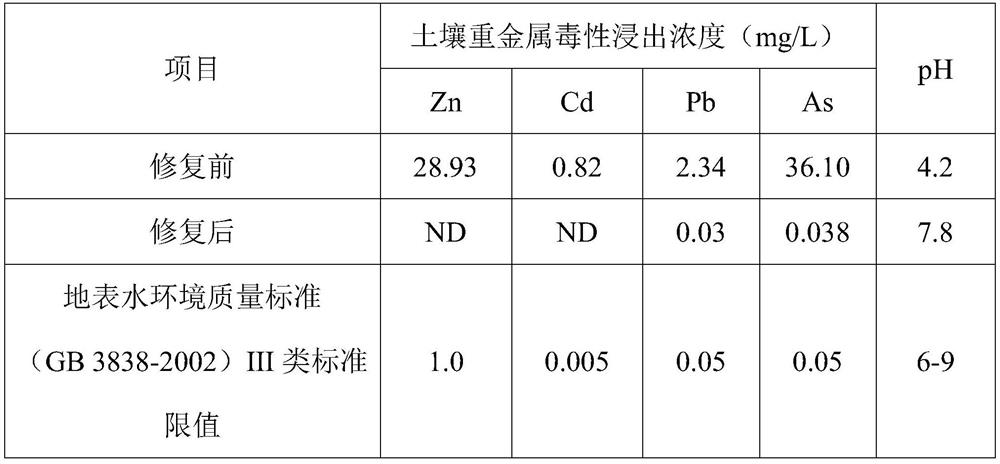

Embodiment 1

[0045] In a site polluted by heavy metals, the main soil pollutants are Zn, Cd, Pb, and As. Two solid repair materials, activated carbon and alkaline oxide, are selected, and the equipment of the present invention is used for repair and maintenance for one week; the soil before repair and after repair is respectively "Solid waste leaching toxicity leaching method sulfuric acid nitric acid method" (HJ / T 299-2007) and "Solid waste corrosivity determination glass electrode method" (GB / T 15555.12-1995) for the determination of heavy metal toxicity leaching concentration and pH. The results are shown in Table 1. After remediation, the soil reached the remediation target of the heavy metal-contaminated site.

[0046] Table 1 Toxicity leaching concentration and pH value of heavy metals before and after soil remediation

[0047]

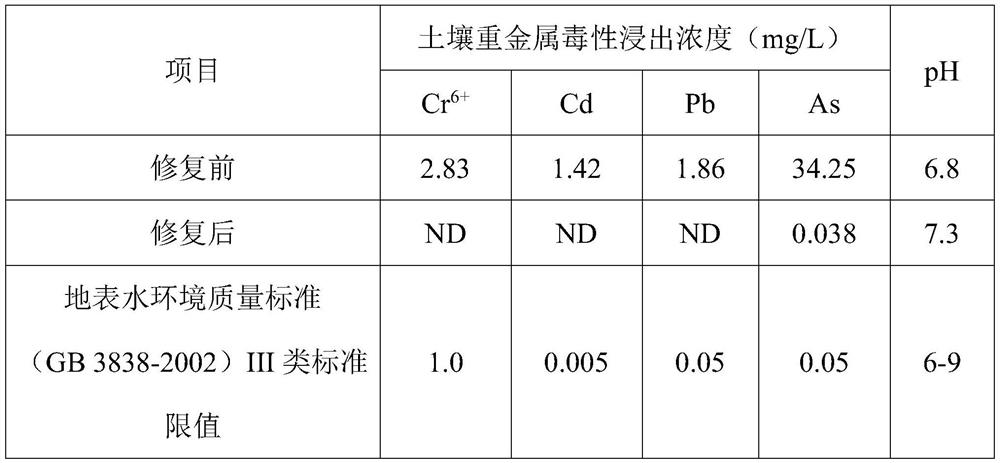

Embodiment 2

[0049] A heavy metal polluted site, the main soil pollutant is Cr 6+ , Cd, Pb, As, select this liquid repair material of calcium polysulfide, adopt the equipment of the present invention to repair, and maintain for one week; before repair and after repair, the soil is respectively according to "solid waste leaching toxicity leaching method sulfuric acid nitric acid method" (HJ / T 299-2007) and "Glass Electrode Method for Determination of Corrosivity of Solid Waste" (GB / T15555.12-1995) for the determination of heavy metal toxicity leaching concentration and pH. The results are shown in Table 2. After remediation, the soil reached the remediation target of the heavy metal-contaminated site.

[0050] Table 2 Toxic leaching concentration and pH value of heavy metals before and after soil remediation

[0051]

[0052] The equipment of the present invention completes a series of processes such as screening, crushing, dosing, and mixing of polluted soil through the cooperation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com