Device and process for preparing nanometer cerium oxide powder in supercritical water medium

A technology of nano-cerium oxide and supercritical water, which is applied in the direction of cerium oxide/cerium hydroxide, rare earth metal oxide/hydroxide, lanthanide oxide/hydroxide, etc., which can solve the problem of high raw material cost and industrial production Difficulty and other issues, to achieve the effect of fast response time, short cycle, and improved particle hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

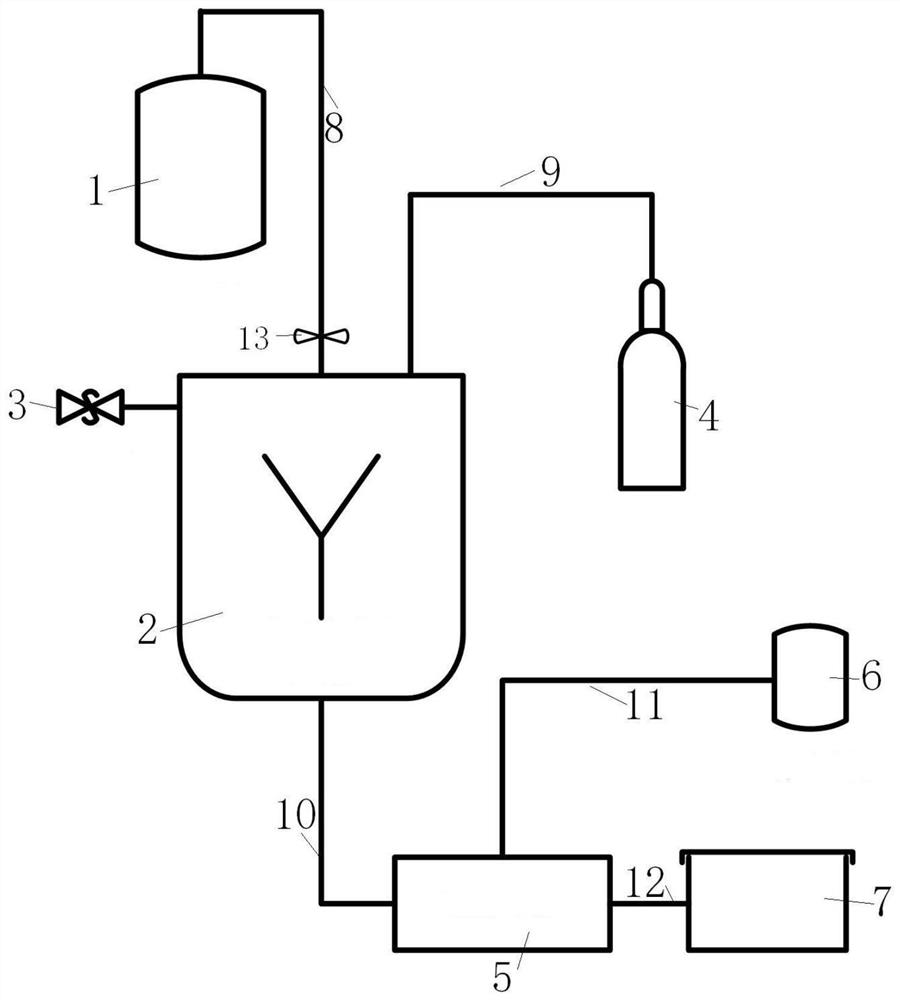

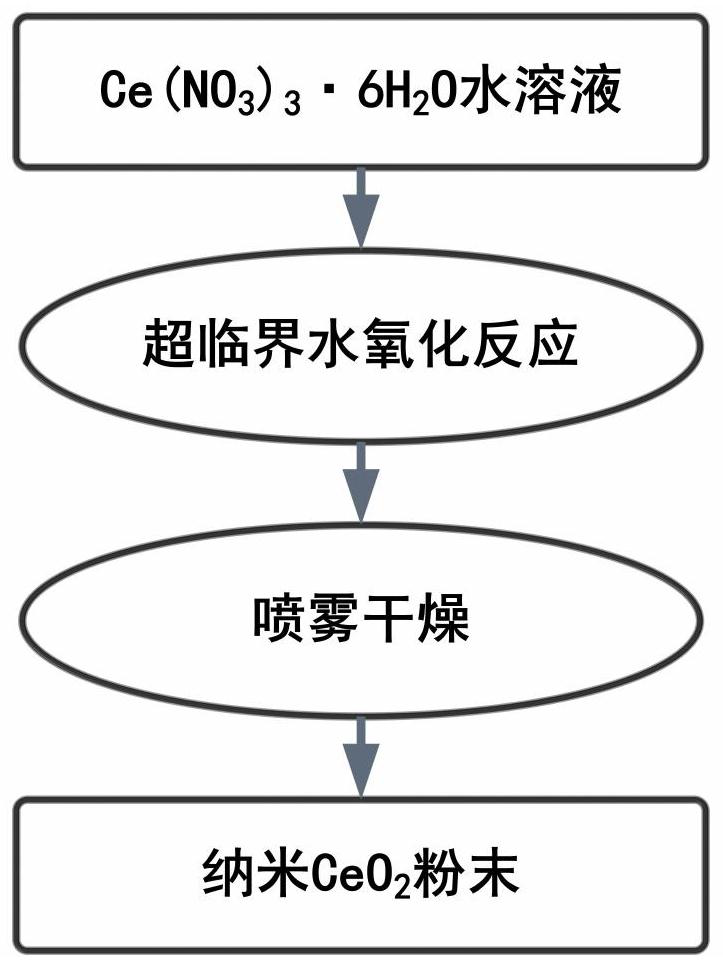

[0043] A kind of technology that prepares nano cerium oxide powder in supercritical water medium, described technology adopts such as figure 1 The supporting equipment shown, the specific steps are as follows:

[0044] Ce(NO 3 ) 3 ·6H 2 O solution, put the prepared raw materials into the storage tank, set the temperature of the preheater to 120°C, and the temperature of the reactor to 400°C, when the temperature reaches the predetermined value, turn on the plunger pump, and the liquid passes through the preheater After preheating, enter the reaction kettle. When the liquid filling degree in the kettle reaches 20%, stop feeding, turn on the magnetic stirrer, set the speed at 300r / min, open the gas cylinder valve, and set the gas pressure to 23MPa. When the pressure in the kettle reaches 23MPa, that is, the temperature and pressure above the supercritical point of water, close the valves of the gas cylinder and the reactor, and react the raw materials in the closed reactor fo...

Embodiment 2

[0049] A kind of technology that prepares nano cerium oxide powder in supercritical water medium, described technology adopts such as figure 1 For the device shown, the specific steps are as follows:

[0050] Ce(NO 3 ) 3 ·6H 2 O solution, put the prepared raw materials into the storage tank, set the temperature of the preheater to 120°C, and the temperature of the reactor to 450°C, when the temperature reaches the predetermined value, turn on the plunger pump, and the liquid passes through the preheater After preheating, enter the reaction kettle. When the liquid filling degree in the kettle reaches 20%, stop feeding, turn on the magnetic stirrer, set the speed at 300r / min, open the gas cylinder valve, and set the gas pressure to 45MPa. When the pressure in the kettle reaches 45MPa, close the valves of the gas cylinder and the reactor, and react the raw materials in the closed reactor for 60 minutes. After the reaction, the liquid enters the spray dryer through the pipeline...

Embodiment 3

[0054] A kind of technology that prepares nano cerium oxide powder in supercritical water medium, described technology adopts such as figure 1 For the device shown, the specific steps are as follows:

[0055] Ce(NO 3 ) 3 ·6H 2 O solution, put the prepared raw materials into the storage tank, set the temperature of the preheater to 120°C, and the temperature of the reactor to 400°C, when the temperature reaches the predetermined value, turn on the plunger pump, and the liquid passes through the preheater After preheating, enter the reaction kettle. When the liquid filling degree in the kettle reaches 60%, stop feeding, turn on the magnetic stirrer, set the speed at 300r / min, open the gas cylinder valve, and set the gas pressure to 30MPa. The pressure in the kettle reaches 30MPa, close the valve of the gas cylinder and the reactor, and react the raw materials in the closed reactor for 30 minutes. After the reaction, the liquid enters the spray dryer through the pipeline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com