Method for preparing azelaic acid, tridecanedioic acid and other long-chain dicarboxylic acids from high erucic acid rapeseed oil

A technology of thirteen carbon dibasic acid and rapeseed oil, which is applied in the field of long-chain dibasic acid, can solve the problems of unsustainable development, large odor, long production cycle, etc., so as to improve the gas utilization rate and speed up the reaction Speed, the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

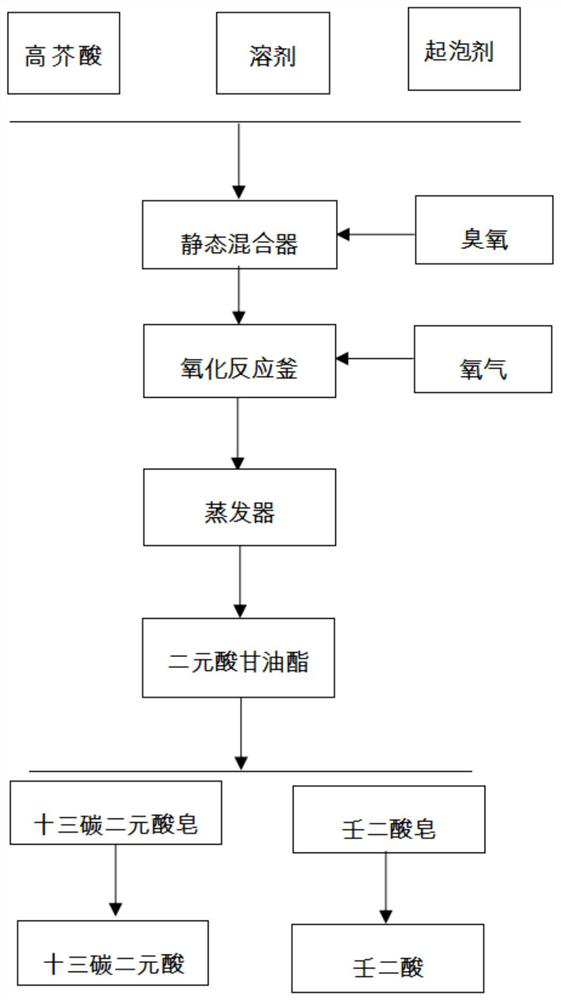

Image

Examples

Embodiment 1

[0027] A kind of method adopting high erucic acid rapeseed oil to prepare long-chain dibasic acids such as azelaic acid, tridecane dibasic acid, comprises the following steps:

[0028] Step 1, the C2~C9 saturated fatty acid of 300Kg high erucic acid rapeseed oil (the actual content of erucic acid is 50%, oleic acid content 18%, linoleic acid content 28%), 500Kg (containing 45% nonanoic acid, 35% % hexanoic acid, the rest are monobasic saturated fatty acids of other C2~C8) and 10Kg foaming agent tripropylene glycol methyl ether are mixed and then added in the ozonation reactor, maintained stirring at a speed of 100rpm and continuously fed into the ozone through the gas distributor Ozone gas is reacted at 30°C until the peroxide value of the reaction material no longer rises to obtain high erucic acid rapeseed oil ozonide; wherein, the ozone content of the ozonization gas is 100mg / L; The gas flow rate is 300m 3 / h;

[0029] Step 2, transfer the obtained high erucic acid rapese...

Embodiment 2

[0034] A kind of method adopting high erucic acid rapeseed oil to prepare long-chain dibasic acids such as azelaic acid, tridecane dibasic acid, comprises the following steps:

[0035]Step 1, with 300Kg high erucic acid rapeseed oil (the actual content of erucic acid is 45%, oleic acid content 21%, linoleic acid content 28%), the C2~C9 saturated fatty acid of 500Kg (containing 45% nonanoic acid, 35% % hexanoic acid, the rest are monobasic saturated fatty acids of other C2~C8) and 5Kg foaming agent tripropylene glycol methyl ether are mixed and then added in the ozonation reactor, maintained stirring at a speed of 100rpm and continuously fed into ozone through the gas distributor Ozone gas is reacted at 30°C until the peroxide value of the reaction material no longer rises to obtain high erucic acid rapeseed oil ozonide; wherein, the ozone content of the ozonization gas is 150mg / L; The gas flow rate is 250m 3 / h;

[0036] Step 2, transfer the obtained high erucic acid rapesee...

Embodiment 3

[0041] A kind of method adopting high erucic acid rapeseed oil to prepare long-chain dibasic acids such as azelaic acid, tridecane dibasic acid, comprises the following steps:

[0042] Step 1, the C2~C9 saturated fatty acid of 500Kg high erucic acid rapeseed oil (the actual content of erucic acid is 50%, oleic acid content 18%, linoleic acid content 28%), 1000Kg (containing 45% nonanoic acid, 35% % caproic acid, the rest are monobasic saturated fatty acids of other C2~C8) and 10Kg foaming agent tripropylene glycol methyl ether foaming agent are mixed and added in the ozonation reaction kettle, maintain stirring with the speed of 100rpm and continue through the gas distributor Feed ozonized gas, react under the condition of 40 ℃, until the peroxide value of the reaction material no longer rises, obtain high erucic acid rapeseed oil ozonide; Wherein, the ozone content of ozonized gas is 120mg / L; The flow rate of the ozonated gas is 400m 3 / h;

[0043] Step 2, transfer the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com