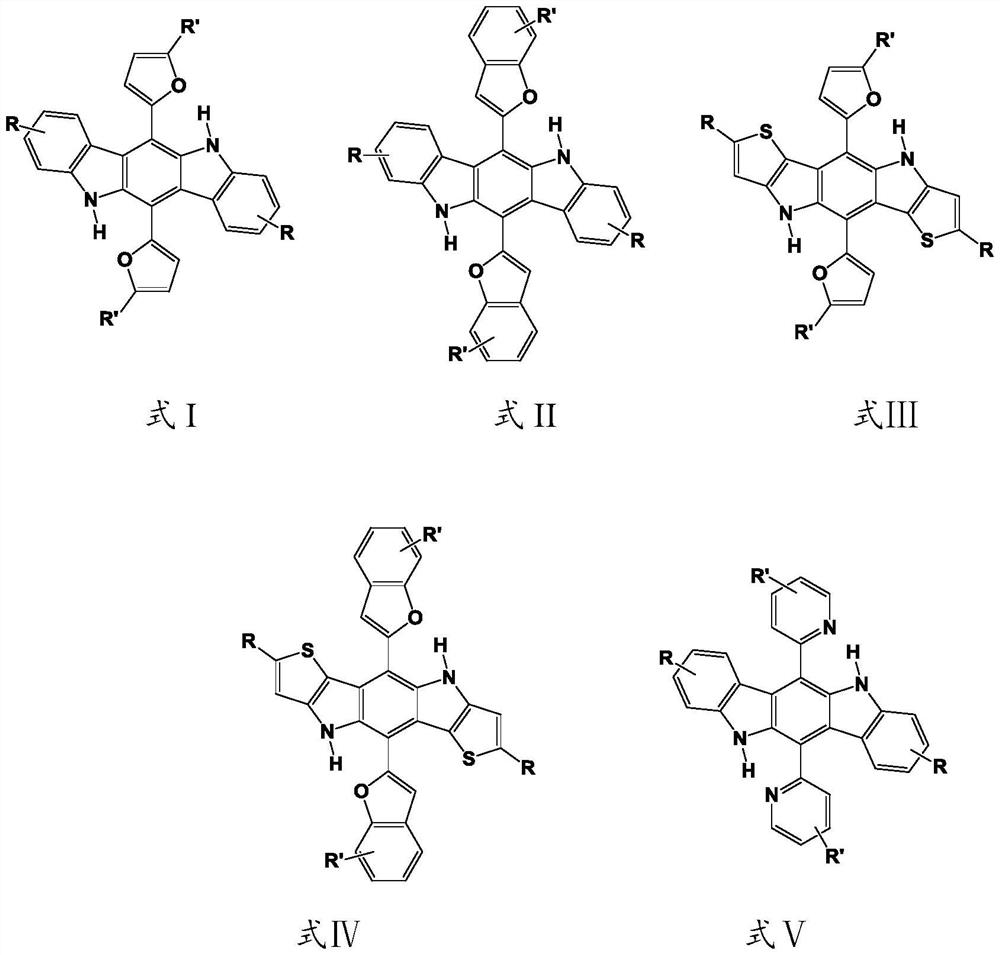

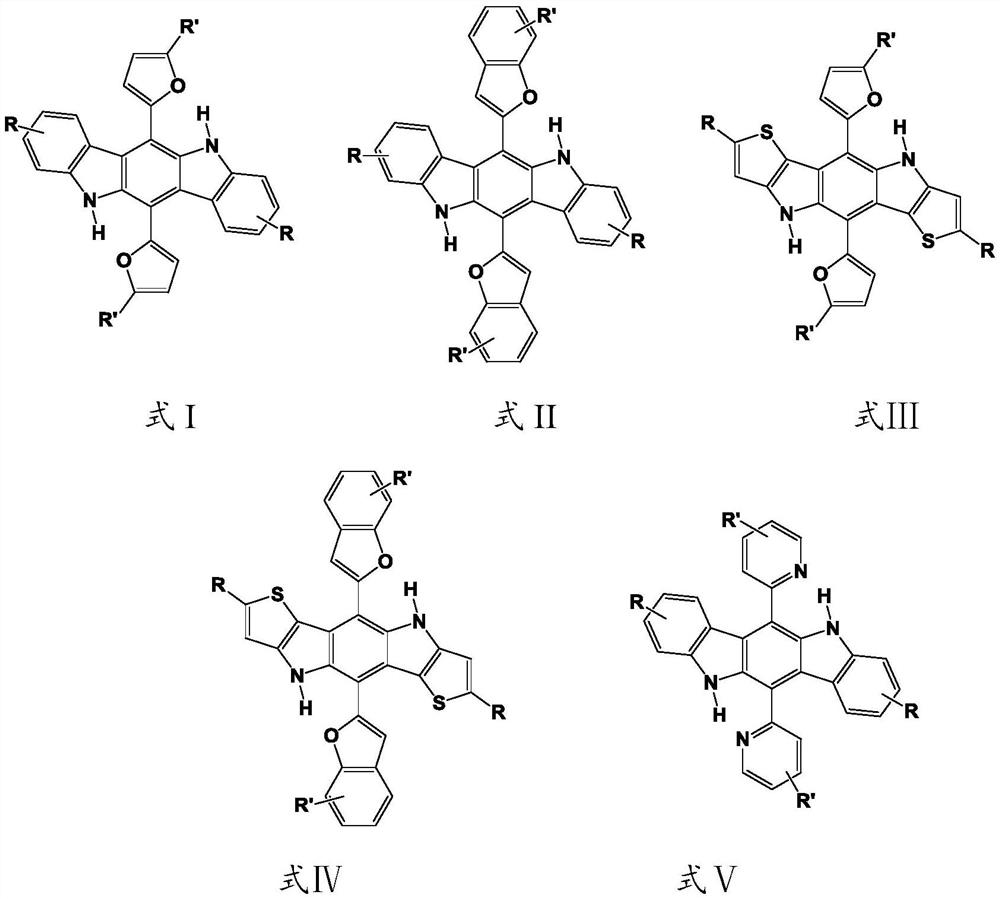

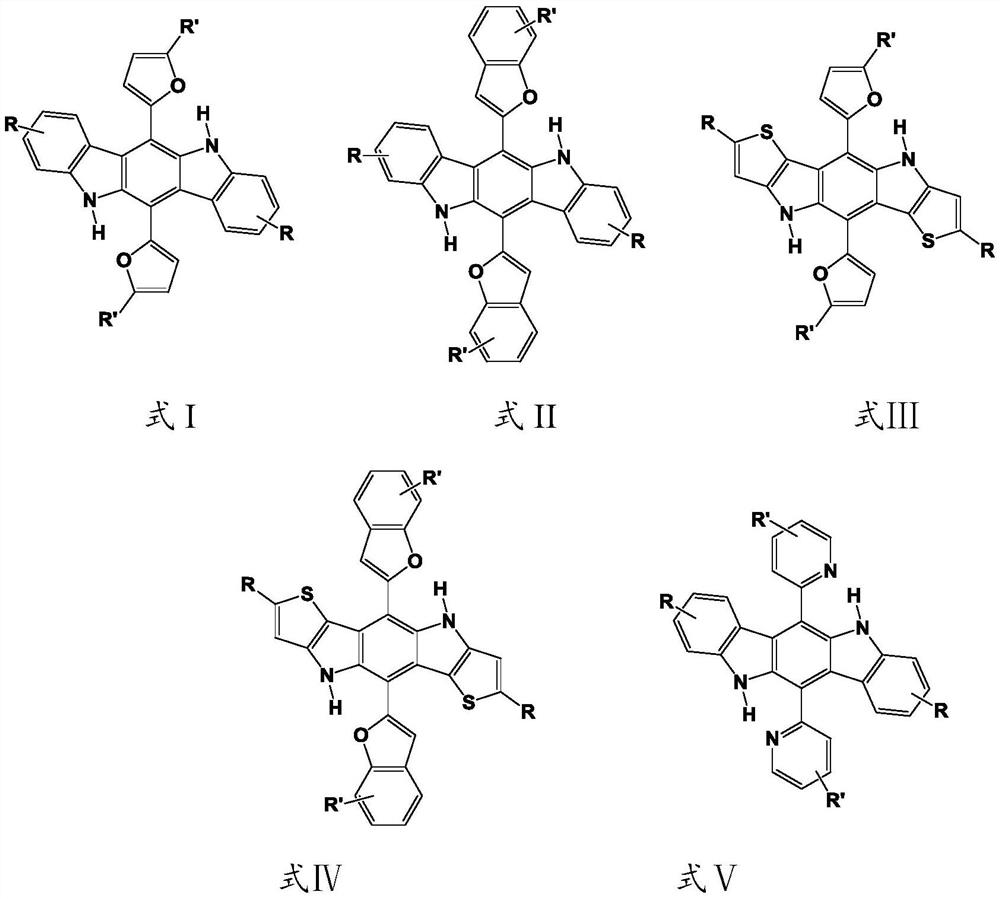

Cross-shaped semiconductor materials for explosive detection as well as preparation method and application of cross-shaped semiconductor materials

A semiconductor, cross-type technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, analytical materials, etc., can solve problems such as changing molecular stacking, difficulty in device recovery and reuse, and degrading device performance, achieving device performance recovery, high Effect of flatness, good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a cross-shaped semiconductor material used for explosive detection, comprising the following steps:

[0035]S1: Add R-pyrrole compound and alkylamine salt to organic solvent I, continue to add R`-furan containing aldehyde group or R`-pyridine containing aldehyde group, and catalyst I, control the temperature, and reflux Reaction, after the reaction is completed and the temperature is lowered, the reaction mixture is filtered and dried to obtain a solid reaction crude product. Among them, the alkylamine salt plays the role of phase transfer catalysis in the reaction, and promotes the reaction of R-pyrrole compound with aldehyde-based R'-furan or aldehyde-containing R'-pyridine. It should be noted that the solid reaction crude product obtained in this step is a mixture of the target product and its isomers.

[0036] S2: Take the solid reaction crude product and catalyst II prepared in step S1 and add them to orga...

Embodiment 1

[0053] A cross-shaped semiconductor material for explosive detection, specifically compound M1 having the following structure,

[0054]

[0055] First the reaction raw materials indole (0.02mol) and tetrabutylammonium iodide (0.002mol) solution are joined in the two-port reaction bottle (250ml) that contains acetonitrile solvent (50ml), then add pyridine-2-carboxaldehyde (0.02 mol) and HBF 4 (0.002mol), the reaction temperature was controlled at 80°C, and the reflux reaction was carried out for 10h. After the reaction was completed and the temperature was lowered, the reaction mixture was filtered, washed with acetonitrile solution (50 ml), and dried to obtain a solid reaction crude product.

[0056] Then add acetonitrile solution (50ml) and I in the solid reaction crude product 2 (0.002mol), control the reaction temperature at 80°C, and continue the reflux reaction for 14h. After the reaction is completed and the temperature is lowered, the reaction mixture is poured int...

Embodiment 2

[0062] A cross-shaped semiconductor material for explosive detection, specifically compound M2 having the following structure,

[0063]

[0064] First, the reaction raw materials indole (0.02mol) and tetrabutylammonium iodide (0.001mol) solution are added in the two-port reaction flask (250ml) that contains acetonitrile solvent (60ml), then add 5-octylfuran-2 -Formaldehyde (0.02mol) and HBF 4 (0.001mol), the reaction temperature was controlled at 80°C, and the reflux reaction was carried out for 14h. After the reaction was completed and the temperature was lowered, the reaction mixture was filtered, washed with acetonitrile solution (60 ml), and dried to obtain a solid reaction crude product.

[0065] Then add acetonitrile solution (50ml) and I in the solid reaction crude product 2 (0.001mol), control the reaction temperature at 80°C, and continue the reflux reaction for 10h. After the reaction is completed and the temperature is lowered, the reaction mixture is poured in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com