Oxygen/sulfur alkylated bithiophene donor unit based D-A type conjugated polymer and preparation method and application thereof

A conjugated polymer, D-A technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of high-efficiency devices such as complicated process and few types, and achieve improved solubility, good planarity, Effect of Optimizing Crystallization Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Donor unit 5-bromo-2-(5-bromo-3-(2-butyloctylthio)thiophen-2-yl)-3-(2-butyloctyloxy)thiophene (BTOSR-Br 2 ) or 5-bromo-2-(5-bromo-3-(2-butyloctylthio)thiophen-2-yl)-3-(2-butyloctylthio)thiophene (BTSR-Br 2 )Synthesis.

[0049] BTOSR-Br 2 or BTSR-Br 2 The synthetic route of is as follows:

[0050]

[0051] 1.1 Synthesis of 3-(2-butyloctylthio)thiophene

[0052] In a 250mL three-necked flask, 3-bromothiophene (8.2g, 50.31mmol), 2-butyloctane-1-thiol (11.2g, 55.34mmol), N,N-diisopropylethylamine ( 7.15g, 55.34mmol), tris(dibenzylideneacetone)dipalladium (0.416g, 0.5mmol), 1,1'-bis(diphenylphosphino)ferrocene (0.558g, 1.00mmol), toluene ( 80mL), under the condition of nitrogen protection, stirred and refluxed in an oil bath at 110°C for 24h. Stop the reaction, cool to room temperature, pour the reaction solution into 60mL water, extract with dichloromethane (3×30mL), dry over anhydrous magnesium sulfate, filter, spin dry under reduced pressure to remove the organic...

Embodiment 2

[0066]

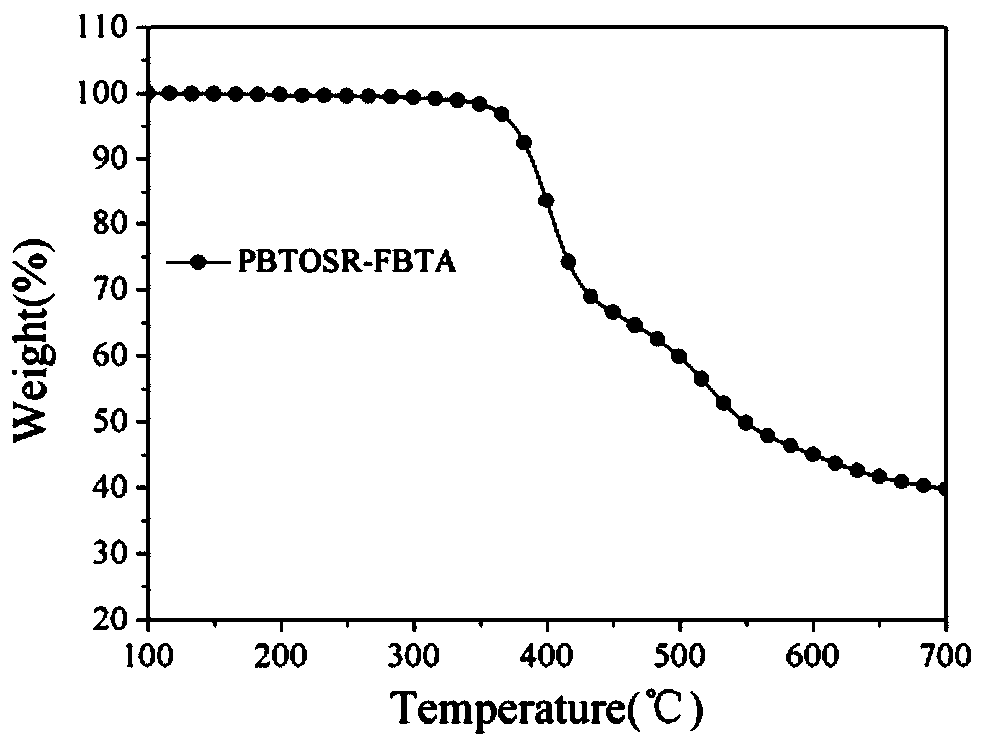

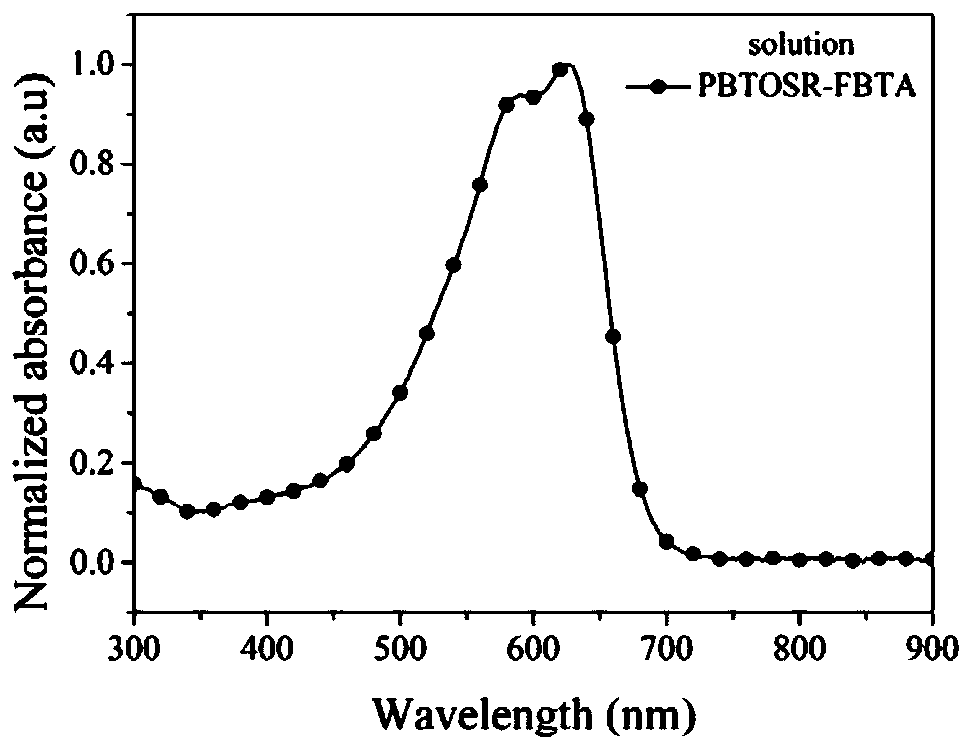

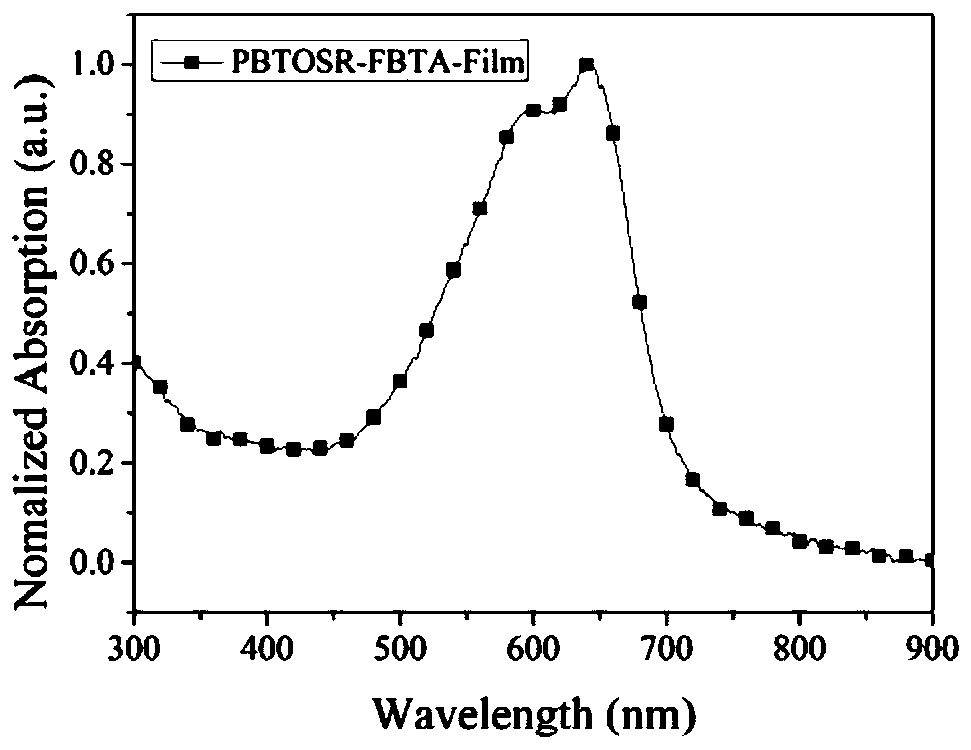

[0067] PBTOSR-FBTA

[0068] Synthesis of polymer PBTOSR-FBTA

[0069] In a 10mL single-necked bottle, add BTOSR-Br in sequence 2 (0.15g, 0.21mmol), 2-(2-ethylhexyl)-5,6-difluoro-4,7-bis(5-(trimethyltinyl)thienyl)-2H-benzo[d ][1,2,3]triazole (0.16g, 0.21mmol), tris(dibenzylideneacetone)dipalladium (5.8mg), tris(o-tolylyl)phosphorus (7.72mg), HPLC toluene 6mL, Liquid nitrogen freezing pumping and deoxygenation, thawing after each freezing pumping, repeated three times, the reaction was placed in a 110°C constant temperature pot, and the reaction changes were observed at all times. After the reaction stopped, dilute with chlorobenzene and settle in methanol, suction filter, Soxhlet extract and wash the crude product (methanol-ether-acetone-dichloromethane-trichloromethane-chlorobenzene), after concentration, flash column chromatography purification, Concentrate, settle with methanol, filter with suction, and dry in vacuo to obtain 167 mg of a black solid product. ...

Embodiment 3

[0071] Synthesis of polymer PBTSR-FBTA

[0072]

[0073] PBTSR-FBTA

[0074] The synthesis and purification steps of polymer PBTSR-FBTA are the same as those of polymer PBTOSR-FBTA. Finally, 118 mg of a black solid product was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com