A kind of preparation method of protein site-directed pegylation modification

A technology of PEGylation and polyethylene glycol is applied in the field of protein modification to achieve the effects of reducing commercial production costs, good stability and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

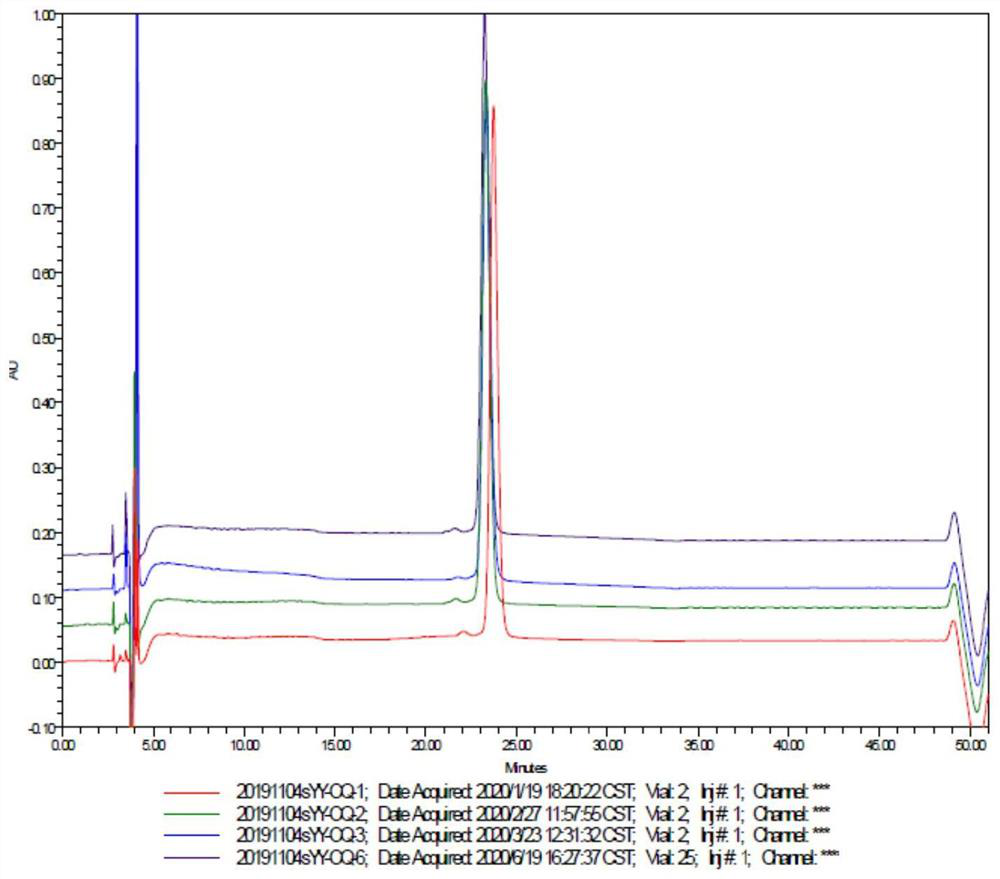

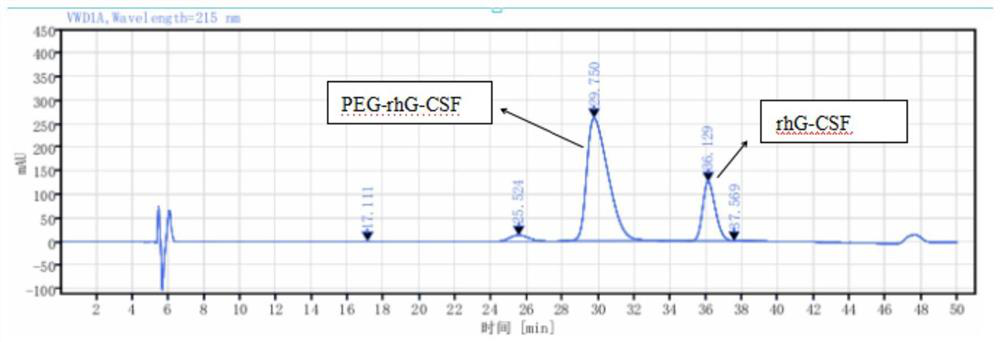

[0047] rhG-CSF reaction solution (40ml, concentration 3mg / ml), containing 100mM sodium phosphate, pH5.0, also contains 120mM MVB6 (vitamin B6), after it is fully stirred and frozen (4 ℃), add 5 times the amount of protein Methoxypolyethylene glycol propionaldehyde (MPEG-PALD) (average molecular weight 20 kDa). The reaction mixture was continuously stirred at the same temperature.

[0048] During the reaction, the modification rate of protein was monitored by RP-HPLC. What RP-HPLC used was a C18 250×4.6mm 5 μm column (phenomenex), with 0.1% trifluoroacetic acid aqueous solution and 0.1% trifluoroacetic acid acetonitrile at 1.0 Gradient elution was performed at a flow rate of ml / min.

[0049] The RP-HPLC analysis results at 8, 9, 10, and 11 hours respectively are shown in Table 1:

[0050]

[0051]

Embodiment 2

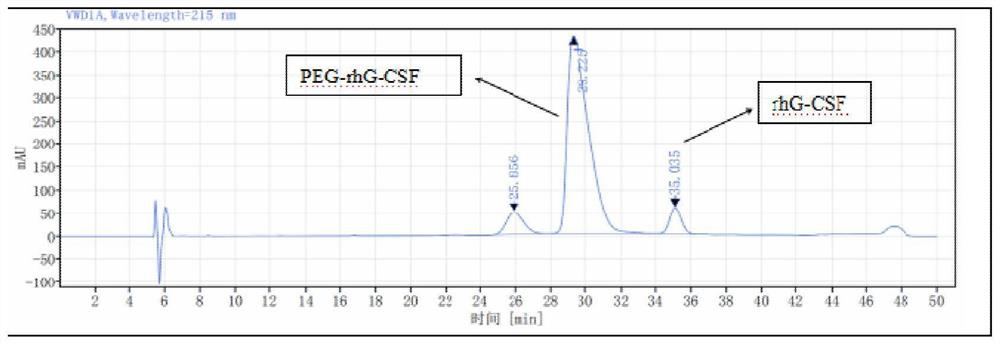

[0053] rhG-CSF reaction solution (40ml, concentration 3mg / ml), containing 100mM sodium phosphate, pH5.0, also contains 40mM NADPH (nicotinamide adenine dinucleotide phosphate), fully stirred and frozen (4 ℃) , Add 5 times the protein amount of methoxypolyethylene glycol propionaldehyde (MPEG-PALD) (average molecular weight is 20kDa). The reaction mixture was continuously stirred at the same temperature.

[0054] During the reaction, the modification rate of protein was monitored by RP-HPLC. What RP-HPLC used was a C18 250×4.6mm 5 μm column (phenomenex), with 0.1% trifluoroacetic acid aqueous solution and 0.1% trifluoroacetic acid acetonitrile at 1.0 Gradient elution was performed at a flow rate of ml / min.

[0055] The RP-HPLC analysis results at 8, 9, 10, and 11 hours respectively are shown in Table 1:

[0056] time RP-HPLC modification rate (%) 8 77.5 9 84.4 10 86.0 11 85.8

Embodiment 3

[0058] rhG-CSF reaction solution (40ml, concentration 3mg / ml), containing 300mM sodium phosphate, pH 7.0, also contains 40mM NADPH (nicotinamide adenine dinucleotide phosphate), fully stirred and frozen (4 ℃) , Add 5 times the protein amount of methoxypolyethylene glycol propionaldehyde (MPEG-PALD) (average molecular weight is 20kDa). The reaction mixture was continuously stirred at the same temperature.

[0059] During the reaction, the modification rate of protein was monitored by RP-HPLC. What RP-HPLC used was a C18 250×4.6mm 5 μm column (phenomenex), with 0.1% trifluoroacetic acid aqueous solution and 0.1% trifluoroacetic acid acetonitrile at 1.0 Gradient elution was performed at a flow rate of ml / min.

[0060] The RP-HPLC analysis results at 8, 9, 10, and 11 hours respectively are shown in Table 1:

[0061] time RP-HPLC modification rate (%) 8 72.3 9 75.1 10 79.5 11 80.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com