Aluminum alloy, and preparation method for plate of aluminum alloy

An aluminum alloy plate and aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems that the high temperature resistance and corrosion resistance of aluminum alloys need to be improved, and affect the fatigue resistance and service life of materials, so as to improve plasticity, hardness, and overall The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing an aluminum alloy plate, comprising the following specific steps:

[0030] S1: Put the aluminum ingot into the smelting furnace to melt, then add the remaining raw materials into the smelting furnace to melt, check the content of each component, pour, and extrude to obtain the ingot.

[0031] S2: Put the cast ingot into the heat treatment furnace, keep it warm at 200-300°C for 1-3 hours, so that the alloy elements can be evenly dissolved into the aluminum matrix, and then hot-roll at 370-390°C, after hot-rolling Cold rolling was performed to obtain a slab.

[0032] S3: put the rolled and deformed slab into a heat treatment furnace for curing treatment, the curing temperature is 650-750°C, and the curing time is 1-2 hours to eliminate rolling work hardening, and obtain an aluminum alloy intermediate plate; an aluminum alloy intermediate plate The thickness ≥ 15mm.

[0033] S4: Water-cooling and quenching the al...

Embodiment 1-7

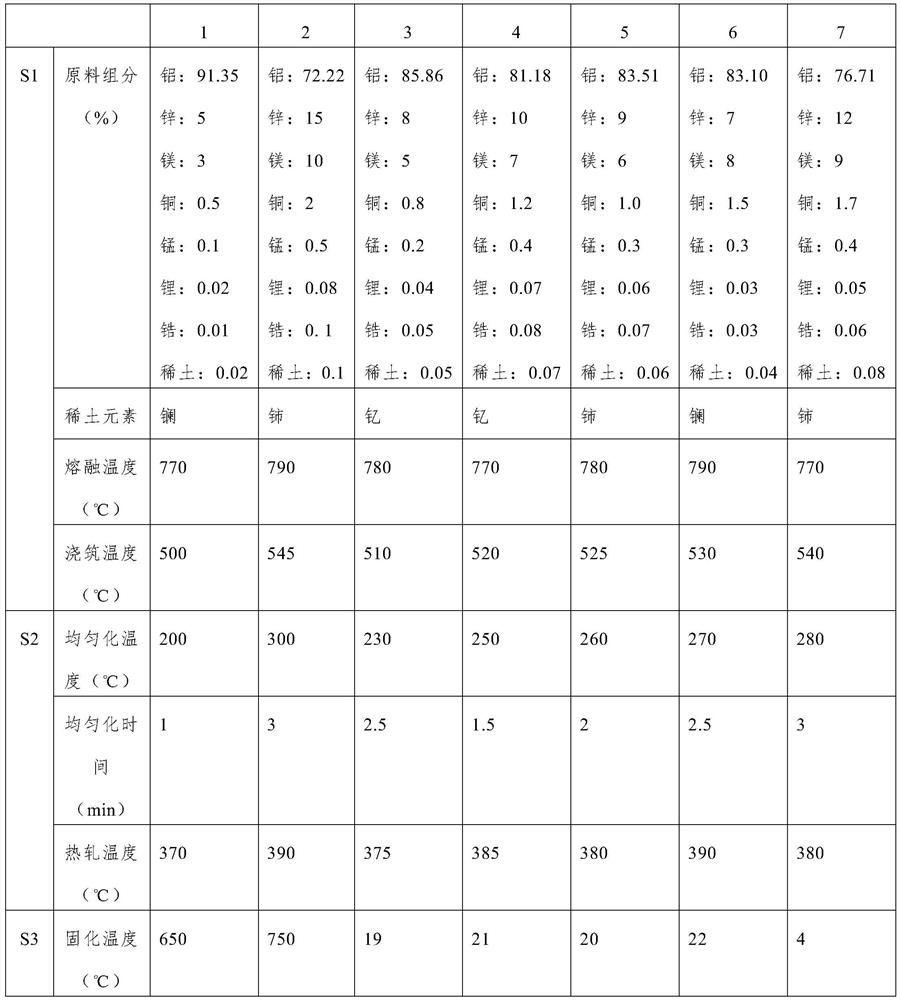

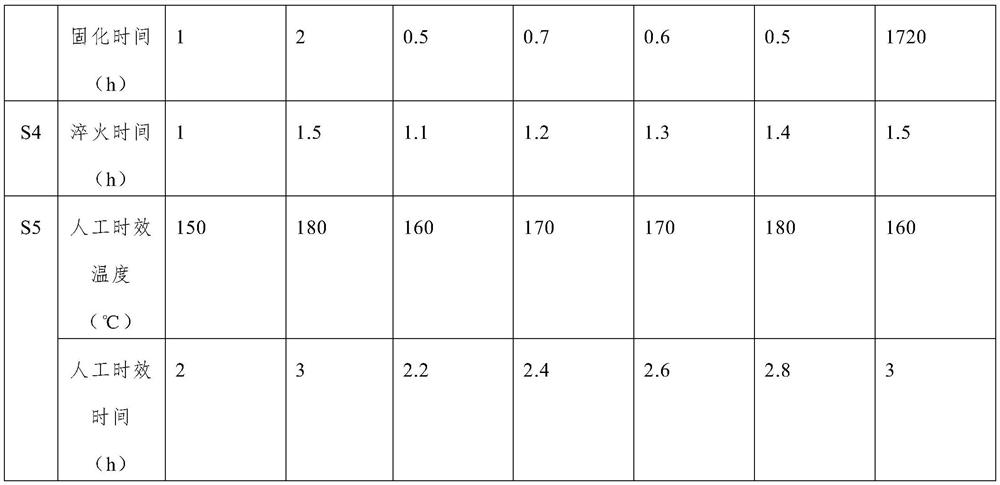

[0041] The process parameter conditions of the aluminum alloy sheet material preparation of embodiment 1-7 are shown in table 1:

[0042] The process parameter condition of aluminum alloy sheet material preparation in the embodiment 1-7 of table 1

[0043]

[0044]

[0045] Example performance test

[0046] The properties of the aluminum alloy plates prepared in Examples 1-7 were tested, and the results are shown in Table 2.

[0047] The performance test result of the aluminum alloy sheet material that table 2 embodiment 1-7 makes

[0048] Example Vickers hardness (Hv) Fracture toughness (MPa.m 1 / 2 )

[0049]It can be seen from Table 2 that the performance indicators of the aluminum alloy plates prepared in Examples 1-7 are: Vickers hardness 165-175Hv, fracture toughness 5.6-6.5MPa.m 1 / 2 , the tensile strength is 544-634MPa, the elongation is 6-15%, and the overall performance is excellent, especially suitable for aluminum alloy plates in the aerospace f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com