Preparation method of molecular metal phthalocyanine (phthalocyanine)/graphene (graphene oxide) composite material

A metal phthalocyanine and composite material technology, which can be used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.2 g of iron phthalocyanine in 20 mL of sulfuric acid, adjust the pH to neutral by diluting in an ice-bath environment, and dry at 60° C. to obtain amorphous iron phthalocyanine.

[0031] Take 0.2 g of graphene oxide powder, add 20 mL of concentrated sulfuric acid with a concentration of 98%, and obtain a uniformly dispersed graphene oxide sulfuric acid dispersion by ultrasonication for 30 minutes.

[0032] Add 0.2 g of iron phthalocyanine powder to the graphene sulfuric acid dispersion while stirring, ultrasonically treat for 30 minutes and then stir for 12 hours to obtain an iron phthalocyanine / graphene oxide composite dispersion, add water to wash until neutral, and obtain a sample.

[0033] Dry at 60° C. for 12 hours in a blast drying oven to obtain a black sample powder.

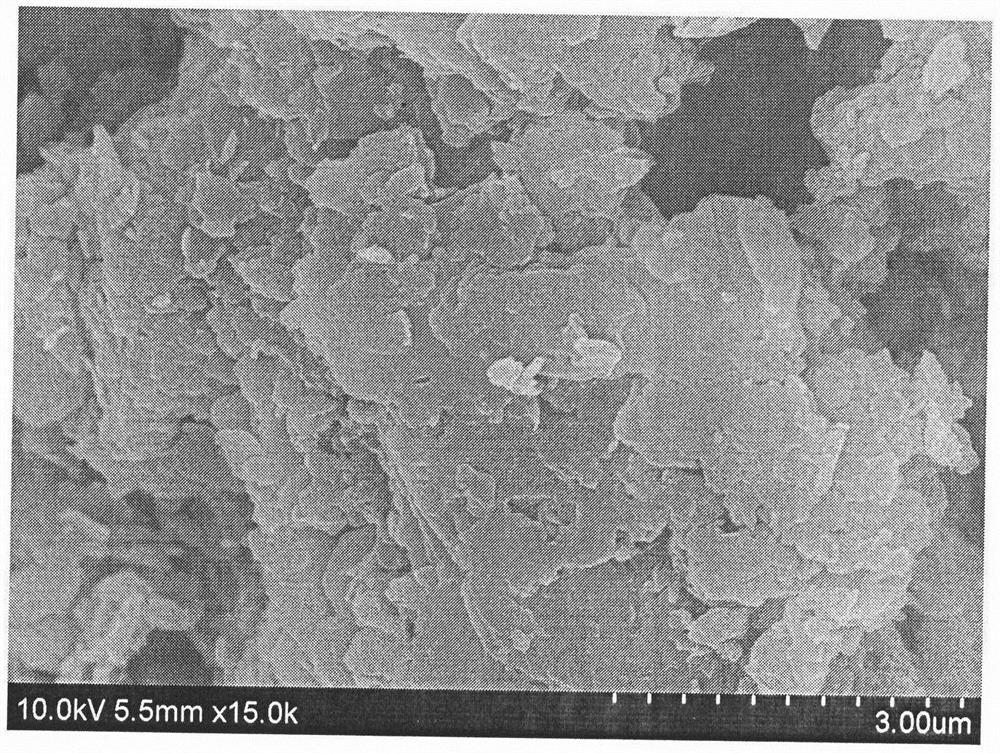

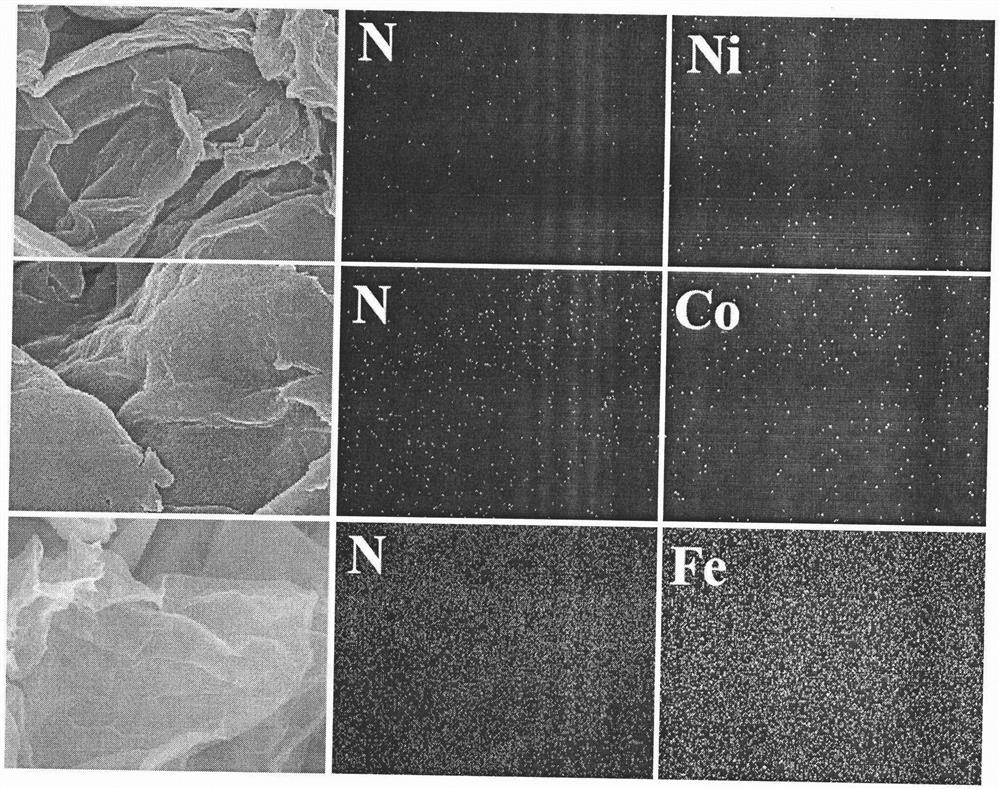

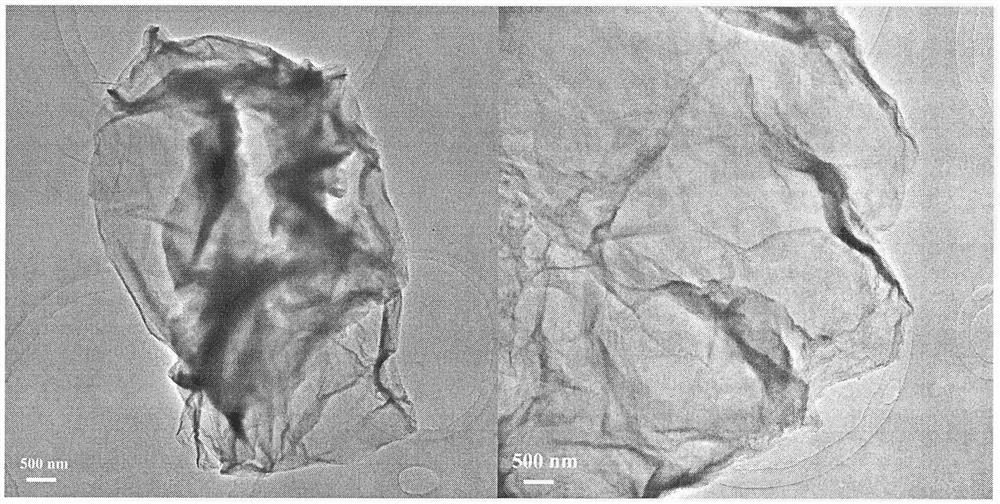

[0034] in figure 1 It is the SEM image of the purified iron phthalocyanine, which obviously changes from a crystal structure to an amorphous structure, figure 2 There is a Mapping im...

Embodiment 2

[0036] Dissolve 0.2 g of nickel phthalocyanine in 20 mL of sulfuric acid, adjust the pH to neutral by diluting in an ice-bath environment, and dry at 60° C. to obtain amorphous nickel phthalocyanine.

[0037] Take 0.2 g of graphene oxide powder, add 20 mL of concentrated sulfuric acid with a concentration of 98%, and obtain a uniformly dispersed graphene oxide sulfuric acid dispersion by ultrasonication for 30 minutes.

[0038] Add 0.2 g of nickel phthalocyanine powder to the graphene sulfuric acid dispersion while stirring, ultrasonically treat for 30 minutes and then stir for 12 hours to obtain a nickel phthalocyanine / graphene oxide composite material dispersion, add water and wash until neutral, and obtain a sample.

[0039] Dry at 60° C. for 12 hours in a blast drying oven to obtain a black sample powder.

Embodiment 3

[0041] Dissolve 0.2 g of cobalt phthalocyanine in 20 mL of sulfuric acid, adjust the pH to neutral by diluting in an ice-bath environment, and dry at 60° C. to obtain amorphous cobalt phthalocyanine.

[0042] Take 0.2 g of graphene oxide powder, add 20 mL of concentrated sulfuric acid with a concentration of 98%, and obtain a uniformly dispersed graphene oxide sulfuric acid dispersion by ultrasonication for 30 minutes.

[0043] Add 0.2 g of cobalt phthalocyanine powder to the graphene sulfuric acid dispersion while stirring, ultrasonically treat for 30 minutes and then stir for 12 hours to obtain a cobalt phthalocyanine / graphene oxide composite material dispersion, add water to wash until neutral, and obtain a sample.

[0044] Dry at 60° C. for 12 hours in a blast drying oven to obtain a black sample powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com