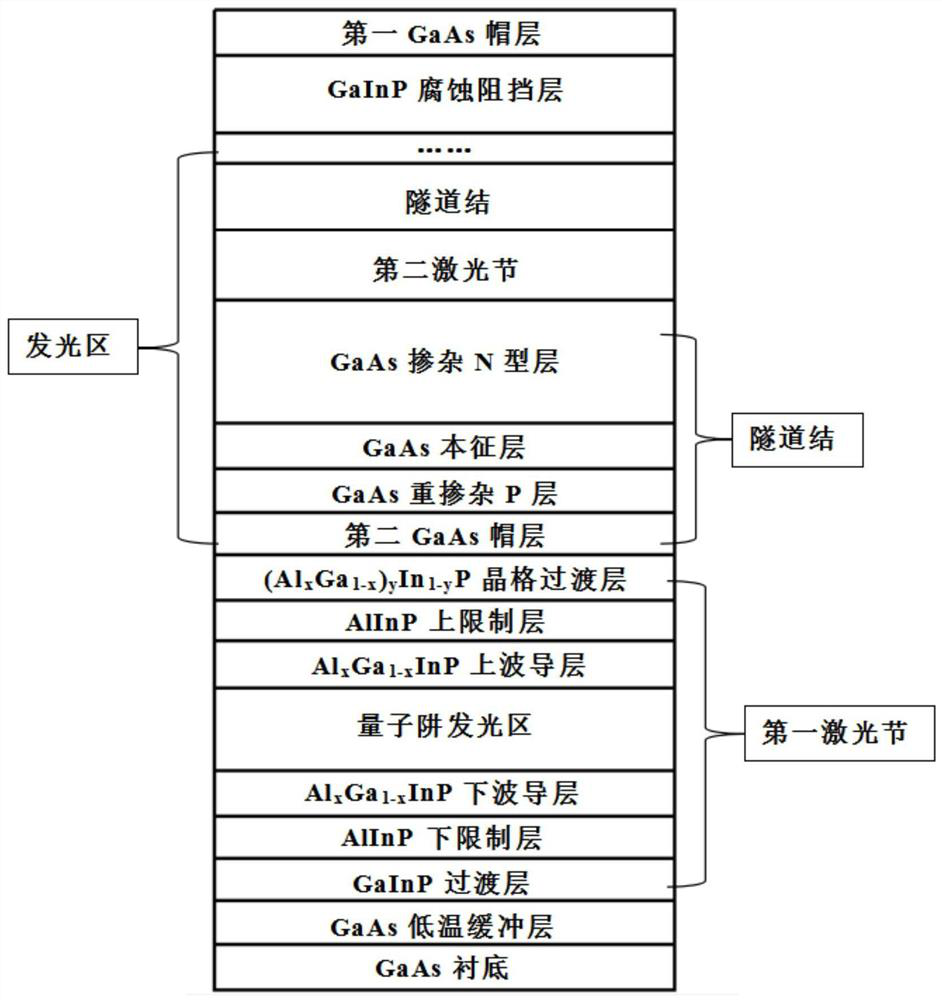

GaAs-based multi-junction red laser and preparation method thereof

A laser, laser technology, applied in the field of optoelectronics, can solve the problems of limiting the application of semiconductor lasers and poor beam quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Step 1: Put the GaAs substrate in the growth chamber of the MOCVD equipment, H 2 The environment is heated to 780°C, baked for 35 minutes, and filled with AsH 3 ;

[0101] Step 2: Slowly lower the temperature to 730°C, continue to feed TMGa and AsH 3 , grow a GaAs low-temperature buffer layer on a GaAs substrate, wherein the thickness of the GaAs low-temperature buffer layer is 200nm, and the doping concentration is 5E17 atoms / cm 3 ;

[0102] Step 3: Slowly lower the temperature to 690°C and continue to feed TMGa, TMIn and PH 3 , a GaInP transition layer is grown on the GaAs low-temperature buffer layer; the doping concentration of the GaInP transition layer is 5E17 atoms / cm 3 ;

[0103] Step 4: Slowly drop the temperature to 660°C, continue to feed TMAl, TMIn and PH 3 , grow an n-type AlInP lower confinement layer on the GaInP transition layer; the thickness of the AlInP lower confinement layer is 0.1um, and the doping concentration is 1E17 atoms / cm 3 ;

[0104...

Embodiment 2

[0120] Step 1: Put the GaAs substrate in the growth chamber of the MOCVD equipment, H 2 The environment is heated to 800°C, baked for 35 minutes, and filled with AsH 3 ;

[0121] Step 2: Slowly lower the temperature to 730-770°C, continue to feed TMGa and AsH 3 , grow a GaAs low-temperature buffer layer on a GaAs substrate, wherein the thickness of the GaAs low-temperature buffer layer is 800nm, and the doping concentration is 6E17 atoms / cm 3 ;

[0122] Step 3: Slowly lower the temperature to 710°C and continue to feed TMGa, TMIn and PH 3 , a GaInP transition layer is grown on the GaAs low-temperature buffer layer; the doping concentration of the GaInP transition layer is 3E18 atoms / cm 3 ;

[0123] Step 4: Slowly drop the temperature to 680°C, continue to feed TMAl, TMIn and PH 3 , grow the n-type AlInP lower confinement layer on the GaInP transition layer; the thickness of the AlInP lower confinement layer is 2um, and the doping concentration is 8E17 atoms / cm 3 ;

[0...

Embodiment 3

[0140] Step 1: Put the GaAs substrate in the growth chamber of the MOCVD equipment, H 2 The environment is heated to 820°C, baked for 35 minutes, and filled with AsH 3 ;

[0141] Step 2: Slowly drop the temperature to 770°C, continue to feed TMGa and AsH 3 , grow a GaAs low-temperature buffer layer on a GaAs substrate, wherein the thickness of the GaAs low-temperature buffer layer is 1500nm, and the doping concentration is 6E18 atoms / cm 3 ;

[0142] Step 3: Slowly lower the temperature to 690-730°C, and continue to feed TMGa, TMIn and PH 3 , grow a GaInP transition layer on the GaAs low-temperature buffer layer; the doping concentration of the GaInP transition layer is 5E18 atoms / cm 3 ;

[0143] Step 4: Slowly drop the temperature to 700°C, continue to feed TMAl, TMIn and PH 3 , grow the n-type AlInP lower confinement layer on the GaInP transition layer; the thickness of the AlInP lower confinement layer is 4um, and the doping concentration is 5E18 atoms / cm 3 ;

[0144...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com