Anticorrosive shaving board and preparation method thereof

A technology of particleboard and shavings, which is applied in the field of wood processing, can solve the problems that affect the production and life of particleboard, affect market promotion and application, and cause serious indoor musty smell, etc., achieve enhanced bond strength, prevent water molecules from entering, and reduce water absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

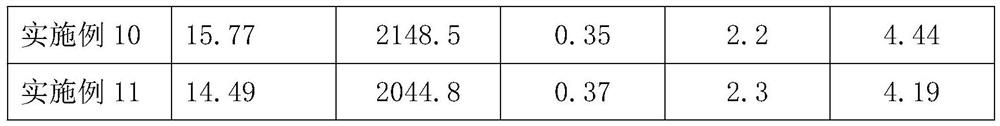

Examples

Embodiment 1

[0023] (1) Preparation of epoxy soybean oil modified polyamine curing agent: first put 5mol of hydroxyethylethylenediamine in a container, heat to 100°C under nitrogen protection, then add 1mol of epoxy soybean oil (epoxy value 4.03 ) slowly dropwise into the container containing hydroxyethylethylenediamine. After the dropwise addition, the temperature was raised to 110° C., and the reaction was terminated after keeping the temperature for 4 hours to obtain a brown-yellow viscous liquid.

[0024] (2) Weigh raw materials: 100 parts of shavings, 35 parts of rice husk, 10 parts of epoxy resin, 10 parts of epoxy soybean oil modified polyamine curing agent, 3 parts of preservative (pentachlorophenol);

[0025] (3) After drying the shavings with a moisture content of 4%, they are evenly mixed with preservatives and rice husk powder crushed through a 300-mesh sieve, and then divided into two equal parts, which are evenly mixed with epoxy resin and curing agent respectively. , mixed ...

Embodiment 2

[0027] With embodiment 1, difference is that step (2) takes by weighing raw materials: 70 parts of shavings, 20 parts of rice husks, 5 parts of epoxy resins, 5 parts of epoxy soybean oil modified polyamine curing agents, preservative (pentachlorophenol )3 copies.

Embodiment 3

[0029] With embodiment 1, difference is that step (2) takes by weighing raw materials: 85 parts of shavings, 30 parts of rice husks, 8 parts of epoxy resins, 8 parts of epoxy soybean oil modified polyamine curing agents, preservative (pentachlorophenol ) 5 copies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com