A coating for improving the adhesion between organic materials and conductive layers and its preparation method

An organic material and conductive layer technology, applied in the field of coatings for improving the adhesion between organic materials and conductive layers and their preparation, to achieve the effects of improving strength, reducing peeling, and being difficult to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

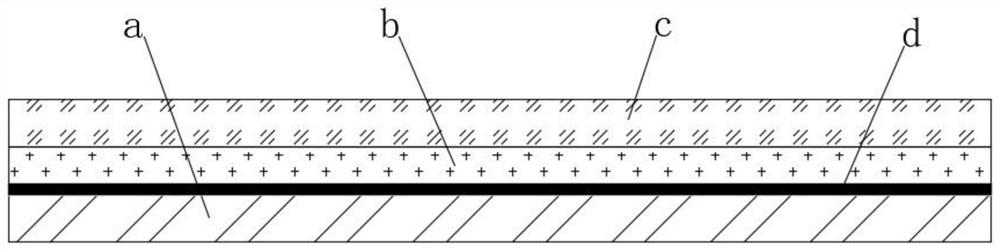

[0052] see figure 1 , a coating for improving the adhesion between an organic material and a conductive layer, comprising the following components in parts by mass: 3.5% polyurethane, 0.05% crosslinking agent, 90% water, 0.03% leveling agent, 7% solvent, all The polyurethane is cationic water-based polyurethane, the crosslinking agent is CX-100, the leveling agent is BYK306, the water is deionized water, and the solvent is ethylene glycol butyl ether, and its preparation process comprises the following steps :

[0053] S1, preparation of cationic waterborne polyurethane;

[0054] S11. Add 102.3g of polytetrahydrofuran ether diol, 17.4g of isocyanate TDI, and 51.3g of acetone into a glass reaction tank, and react at 80 degrees Celsius for 3 hours to form an isocyanate-terminated prepolymer;

[0055] S12, add 12.1g diethylenetriamine and 655g acetone again, continue stirring for 1 hour;

[0056] S13, add 91.5g of water, continue to stir for 1 hour at 50 degrees Celsius;

[0...

Embodiment 2

[0072] see figure 1 , a coating for improving the adhesion between organic materials and conductive layers, comprising the following components in parts by mass: 3% polyurethane, 0.05% crosslinking agent, 88% water, 0.03% leveling agent, 6% solvent, all The polyurethane is cationic water-based polyurethane, the crosslinking agent is CX-100, the leveling agent is BYK306, the water is deionized water, and the solvent is ethylene glycol butyl ether, and its preparation process comprises the following steps :

[0073] S1, preparation of cationic waterborne polyurethane;

[0074] S11. Add 102.3g of polytetrahydrofuran ether diol, 17.4g of isocyanate TDI, and 51.3g of acetone into a glass reaction tank, and react at 80 degrees Celsius for 3 hours to form an isocyanate-terminated prepolymer;

[0075] S12, add 12.1g diethylenetriamine and 655g acetone again, continue stirring for 1 hour;

[0076] S13, add 91.5g of water, continue to stir for 1 hour at 50 degrees Celsius;

[0077] ...

Embodiment 3

[0092] see figure 1 , a coating for improving the adhesion between organic materials and conductive layers, comprising the following components in parts by mass: 4% polyurethane, 0.05% crosslinking agent, 91% water, 0.03% leveling agent, 8% solvent, all The polyurethane is cationic water-based polyurethane, the crosslinking agent is CX-100, the leveling agent is BYK306, the water is deionized water, and the solvent is ethylene glycol butyl ether, and its preparation process comprises the following steps :

[0093] S1, preparation of cationic waterborne polyurethane;

[0094] S11. Add 102.3g of polytetrahydrofuran ether diol, 17.4g of isocyanate TDI, and 51.3g of acetone into a glass reaction tank, and react at 80 degrees Celsius for 3 hours to form an isocyanate-terminated prepolymer;

[0095] S12, add 12.1g diethylenetriamine and 655g acetone again, continue stirring for 1 hour;

[0096] S13, add 91.5g of water, continue to stir for 1 hour at 50 degrees Celsius;

[0097] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com