Infrared radar double-stealth film material and preparation method thereof

A thin-film material and radar technology, which is applied in the field of infrared radar double-stealth thin-film material and its preparation, can solve the problems of poor electromagnetic loss effect, poor stealth effect, and low infrared emissivity, and achieve large electromagnetic loss and excellent radar stealth effect, the effect of low infrared radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

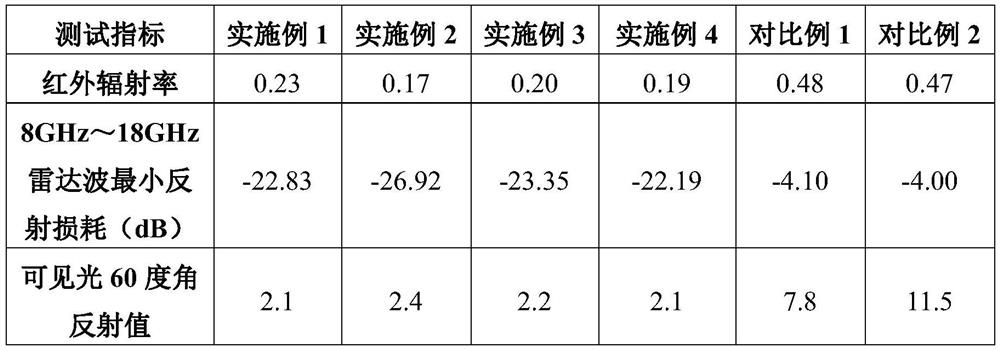

Examples

Embodiment 1

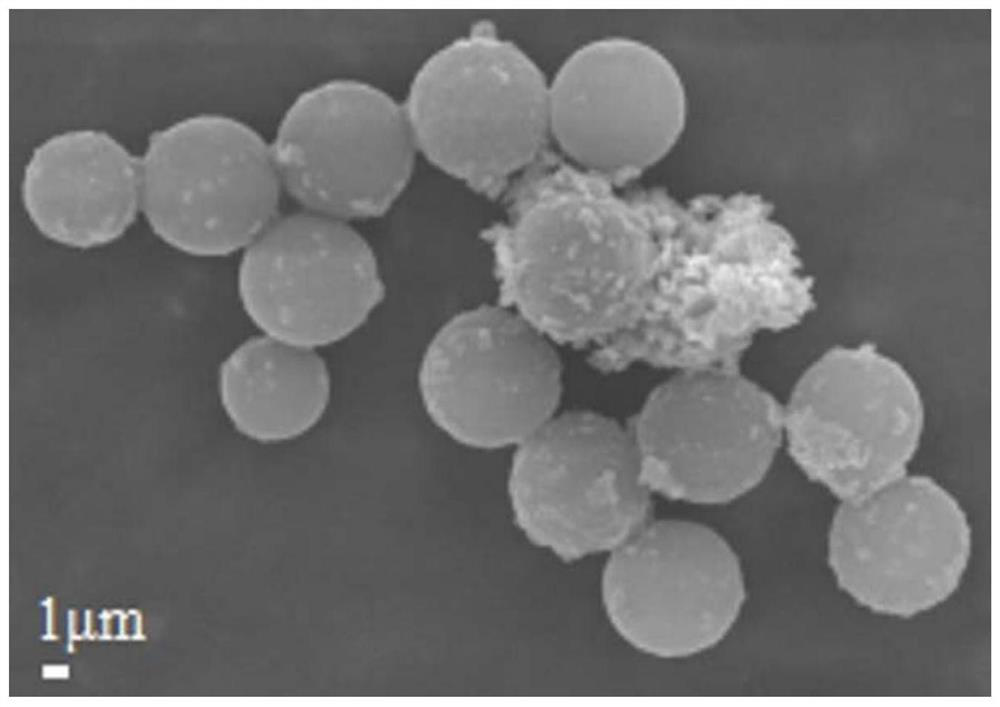

[0046] A kind of functionalized polystyrene microsphere, its preparation method comprises the following steps:

[0047] 1) Disperse 20 parts by mass of styrene and 1 part by mass of cetyltrimethylammonium bromide in 58 parts by mass of ethanol solution (mass fraction 95%), stir and emulsify for 20 minutes under a nitrogen atmosphere to obtain an emulsion , heated up to 70°C, then added 0.5 parts by mass of azobisisobutyronitrile and 1.5 parts by mass of vinyltrimethoxysilane, reacted at 70°C for 12 hours, cooled, filtered with suction, washed the filtered solid with ethanol and distilled water, Then place it in an oven to dry at 50°C to obtain hydrophilic modified polystyrene microspheres;

[0048] 2) Disperse 2.5 parts by mass of hydrophilic modified polystyrene microspheres in 65 parts by mass of SnCl with a concentration of 12g / L 2 solution, and then adjust the SnCl with concentrated hydrochloric acid 2 The pH of the solution was 1, stirred and sensitized for 30 minutes, ...

Embodiment 2

[0055] A kind of functionalized polystyrene microsphere, its preparation method comprises the following steps:

[0056] 1) Disperse 24 parts by mass of styrene and 1 part by mass of cetyltrimethylammonium bromide in 65 parts by mass of ethanol solution (95% mass fraction), stir and emulsify for 15 minutes under a nitrogen atmosphere to obtain an emulsion , heated up to 70°C, then added 1.1 parts by mass of azobisisobutyronitrile and 2.2 parts by mass of vinyltrimethoxysilane, reacted at 70°C for 12 hours, cooled, filtered with suction, washed the filtered solid with ethanol and distilled water, Then place it in an oven to dry at 50°C to obtain hydrophilic modified polystyrene microspheres;

[0057] 2) Disperse 2 parts by mass of hydrophilic modified polystyrene microspheres in 70 parts by mass of SnSO with a concentration of 10 g / L 4 solution, and then adjust the SnSO with concentrated hydrochloric acid 4 The pH of the solution was 1, stirred and sensitized for 30 minutes, f...

Embodiment 3

[0064] A kind of functionalized polystyrene microsphere, its preparation method comprises the following steps:

[0065] 1) Disperse 28 parts by mass of styrene and 1 part by mass of cetyltrimethylammonium bromide in 70 parts by mass of ethanol solution (mass fraction 95%), stir and emulsify for 25 minutes under a nitrogen atmosphere to obtain an emulsion , heated up to 70°C, then added 1.2 parts by mass of azobisisobutyronitrile and 1.8 parts by mass of vinyltrimethoxysilane, reacted at 70°C for 12 hours, cooled, filtered with suction, washed the filtered solid with ethanol and distilled water, Then place it in an oven to dry at 50°C to obtain hydrophilic modified polystyrene microspheres;

[0066] 2) Disperse 3.5 parts by mass of hydrophilic modified polystyrene microspheres in 70 parts by mass of SnF with a concentration of 10g / L 2 solution, and then use concentrated hydrochloric acid to adjust the SnF 2 The pH of the solution was 1, stirred and sensitized for 30 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com