High performance liquid chromatography for efficiently separating and detecting p-benzoquinone in hydroquinone and application thereof

A high-performance liquid chromatography and p-benzoquinone technology, applied in the field of drug analysis, to achieve the effects of high sensitivity, efficient separation and detection, and controllable drug quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

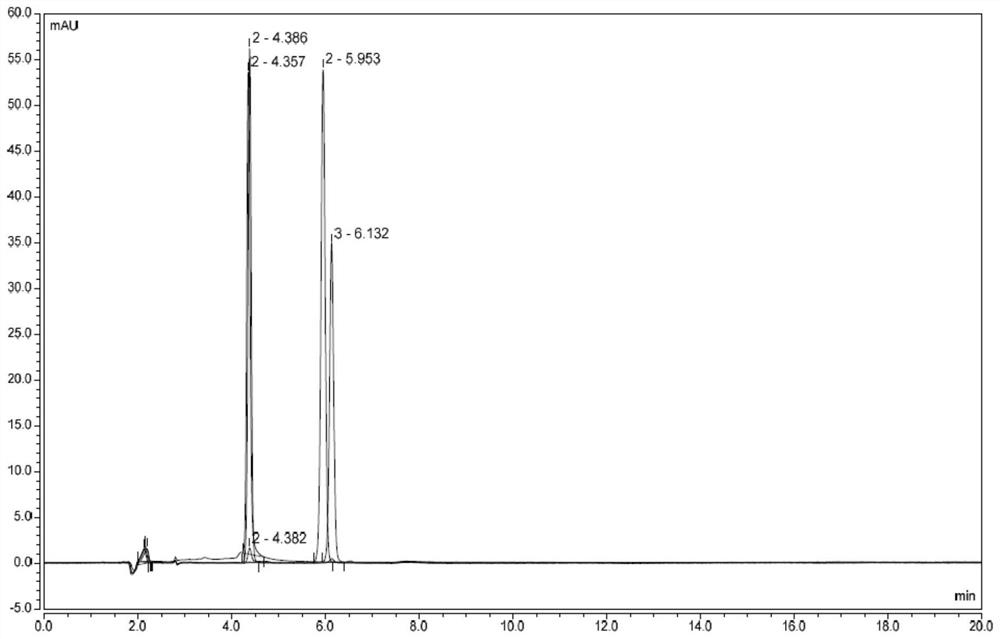

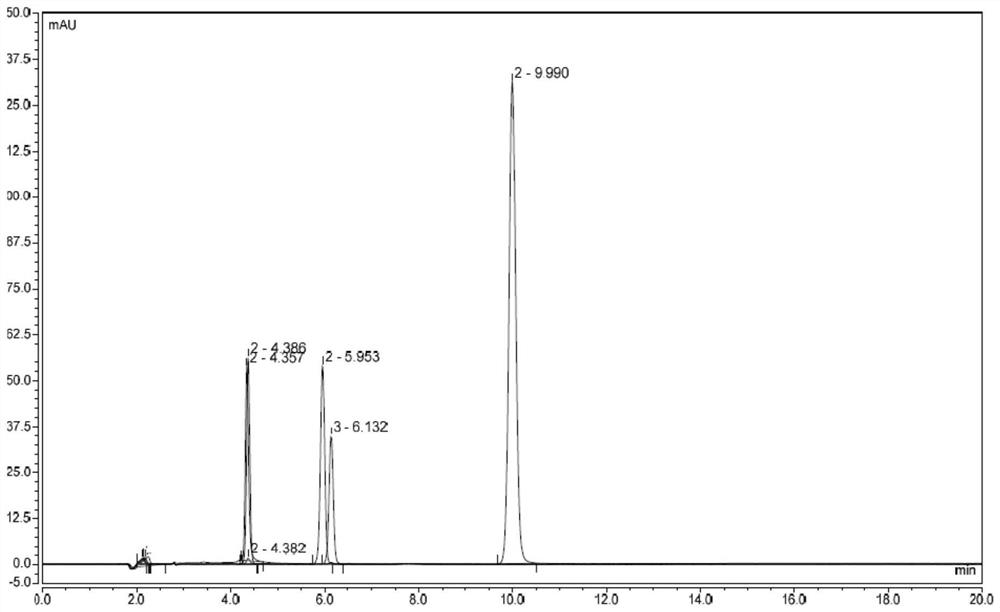

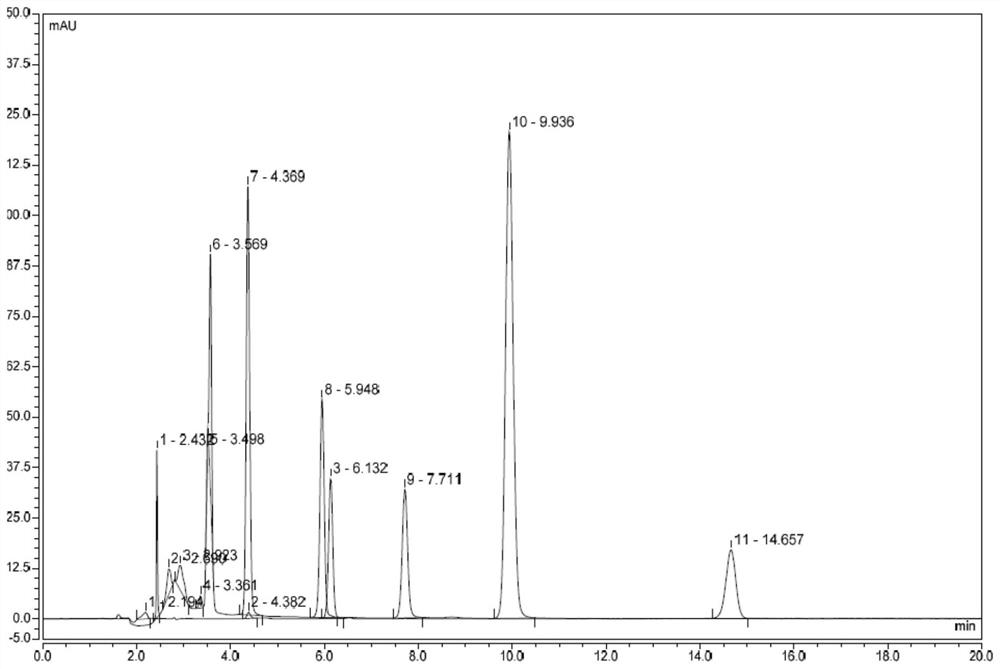

Image

Examples

Embodiment 1

[0141] Example 1 The preparation of hydroquinone of the present invention

[0142] The preparation method of hydroquinone, comprises the steps:

[0143] 1) MnO 2 Add 280g, 430g of 98% sulfuric acid, and 2.0L of water into the reaction flask, slowly add 100g of aniline dropwise at 5-10°C, stir, and gradually raise the temperature to about 25°C until the reaction is complete. The reaction liquid is steam distilled at 60-90°C, and the collected p-benzoquinone condensate is introduced into another reaction flask;

[0144] 2) Under the condition of shading and nitrogen protection, add 42g of iron powder to the collected p-benzoquinone condensate, stir and react for 3-4 hours at 90-100°C, until the reaction is complete, filter, and depressurize the collected filtrate Concentrating to a hydroquinone content of 35% in the concentrated solution;

[0145] 3) Add 550mg of sodium metabisulfite, 2.2g of activated carbon, and 330mg of zinc powder to the concentrated solution, heat to ...

Embodiment 2

[0146] Example 2 The preparation of hydroquinone of the present invention

[0147] The preparation method of hydroquinone, comprises the steps:

[0148] 1) MnO 2 Add 350g, 500g of 98% sulfuric acid, and 2.0L of water into the reaction flask, slowly add 100g of aniline dropwise at 5°C-8°C, stir, and gradually raise the temperature to about 25°C until the reaction is complete. The reaction liquid is steam distilled at 60-90°C, and the collected p-benzoquinone condensate is introduced into another reaction flask;

[0149] 2) Under the conditions of shading and nitrogen protection, add 60g of iron powder to the collected p-benzoquinone condensate, stir and react for 2-3 hours at 90-100°C, until the reaction is complete, filter, collect the filtrate and concentrate under reduced pressure To the hydroquinone content in the concentrated solution is 25%;

[0150] 3) Add 750 mg of sodium pyrosulfite, 3.1 g of activated carbon, and 500 mg of iron powder to the concentrated solutio...

Embodiment 3

[0151] Example 3 The preparation of hydroquinone of the present invention

[0152] The preparation method of hydroquinone, comprises the steps:

[0153] 1) MnO 2 Add 250g, 370g of 98% sulfuric acid, and 2.5L of water into the reaction flask, slowly add 100g of aniline dropwise at 6-10°C, stir, and gradually raise the temperature to about 25°C until the reaction is complete. The reaction liquid is steam distilled at 70-95°C, and the collected p-benzoquinone condensate is introduced into another reaction flask;

[0154] 2) Under the conditions of shading and nitrogen protection, add 31g of iron powder to the collected p-benzoquinone condensate, stir and react at 90-100°C for 2-3 hours, until the reaction is complete, filter, collect the filtrate and concentrate it under reduced pressure to The content of hydroquinone in the concentrated solution is 30%;

[0155] 3) Add 550 mg of sodium pyrosulfite, 2.20 g of activated carbon, and 350 mg of zinc powder to the concentrated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com