Color carbon fiber thermal management device with structural color gradient and preparation method

A structural color, carbon fiber technology, applied in heating element materials, ion implantation plating, coatings, etc., can solve the problems of scarcity, monotonous color of wearable thermal management devices, etc., achieve fast sputtering rate, high color saturation, beautiful color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

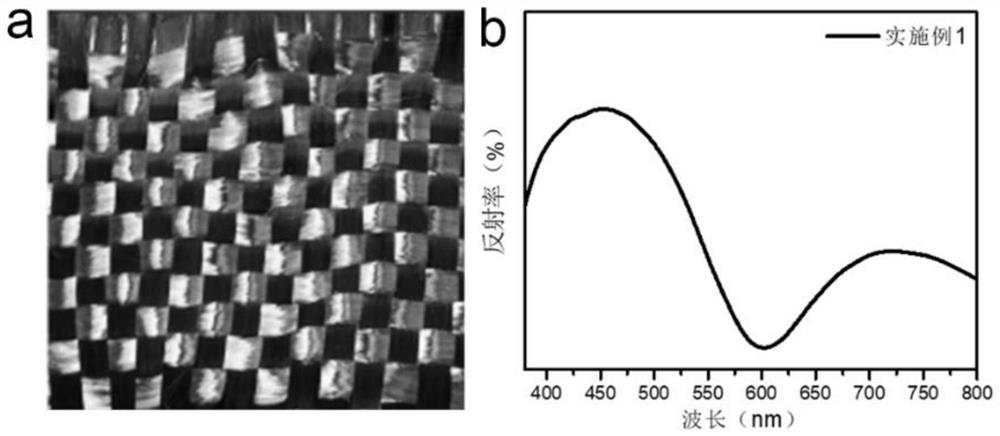

[0042] This embodiment discloses a method for preparing a colored carbon fiber thermal management device with a structural color gradient, specifically as follows:

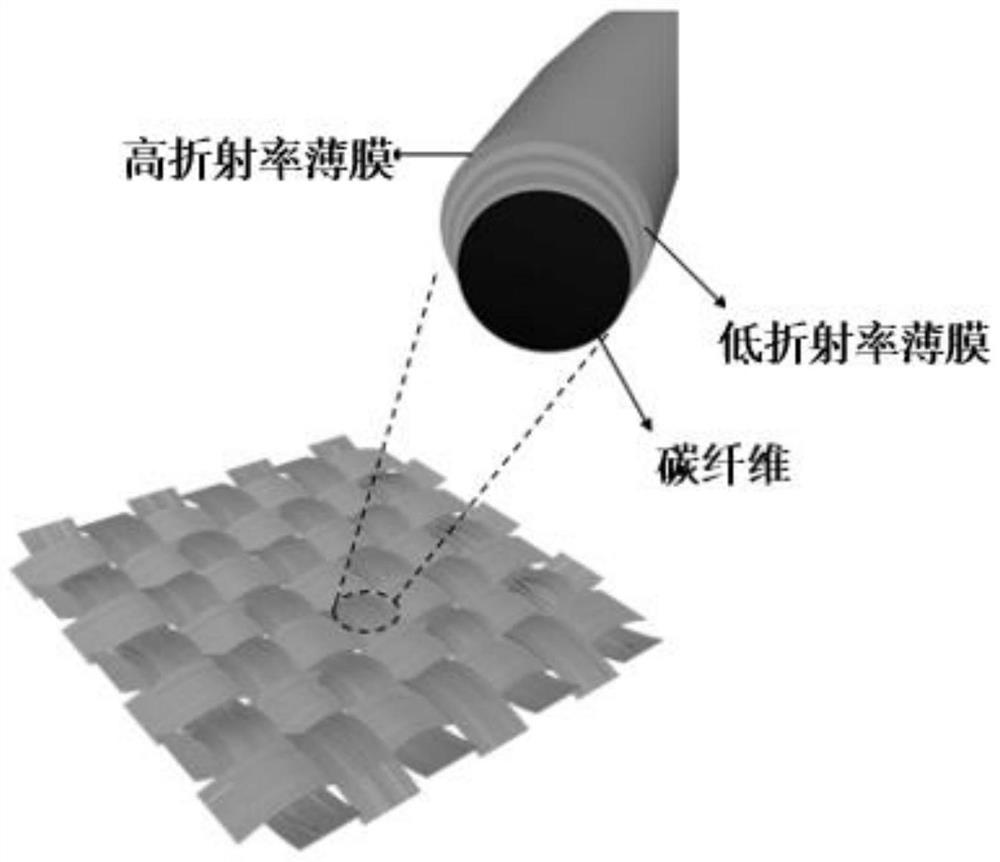

[0043] Put the carbon fiber cloth into acetone and then into ethanol for ultrasonic cleaning for 5 minutes respectively to remove oil and other impurities on the surface of the carbon fiber material, and then put the cleaned carbon fiber material in an oven to dry; then put the treated carbon fiber Put the cloth into 65% concentrated nitric acid and heat it at 65°C for 2 hours, so as to introduce -COOH, -OH and other oxygen-containing groups on the surface of the carbon fiber; then put the activated carbon fiber cloth into the magnetron sputtering instrument In the chamber, the background vacuum of the reaction chamber of the magnetron sputtering instrument was evacuated to 6×10 -4 Pa, argon is the working gas, the purity is 99.99%, the Ar gas flow rate is 20sccm, and the working pressure is 0.5Pa; the distance be...

Embodiment 2

[0045] This embodiment discloses a method for preparing a colored carbon fiber thermal management device with a structural color gradient, specifically as follows:

[0046] Put the carbon fiber cloth into acetone and then into ethanol for ultrasonic cleaning for 5 minutes respectively to remove oil and other impurities on the surface of the carbon fiber material, and then put the cleaned carbon fiber material in an oven to dry; then put the treated carbon fiber Put the cloth into 65% concentrated nitric acid and heat it at 65°C for 2 hours to introduce -COOH, -OH and other oxygen-containing groups on the surface of the carbon fiber; then put the activated carbon fiber cloth into the reaction chamber of the magnetron sputtering instrument In the chamber, the background vacuum of the reaction chamber of the magnetron sputtering instrument was evacuated to 6×10 -4 Pa, argon is the working gas, the purity is 99.99%, the Ar gas flow rate is 20sccm, the working pressure is 0.5Pa; th...

Embodiment 3

[0050] This embodiment discloses a method for preparing a colored carbon fiber thermal management device with a structural color gradient, specifically as follows:

[0051] Put the carbon fiber cloth into acetone and then into ethanol for ultrasonic cleaning for 5 minutes respectively to remove oil and other impurities on the surface of the carbon fiber material, and then put the cleaned carbon fiber material in an oven to dry; then put the treated carbon fiber Put the cloth into 65% concentrated nitric acid and heat it at 65°C for 2 hours, so as to introduce oxygen-containing groups such as -COOH and -OH on the surface of the carbon fiber; then put the activated carbon fiber cloth into the magnetron sputtering chamber , the background vacuum of the magnetron sputtering chamber was evacuated to 6×10 -4 Pa, argon is the working gas, the purity is 99.99%, the Ar gas flow rate is 20sccm, the working pressure is 0.5Pa; the distance between the target and the fabric substrate is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com