System and method for removing heavy metals and chloride ions in evaporative crystallization process of desulfurization wastewater

A technology for desulfurization wastewater, evaporation and crystallization, applied in chemical instruments and methods, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of easy structure blockage of the system, high operating costs, high energy consumption rate, etc., and achieve no wastewater Emissions, high waste liquid concentration, and the effect of saving steam heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

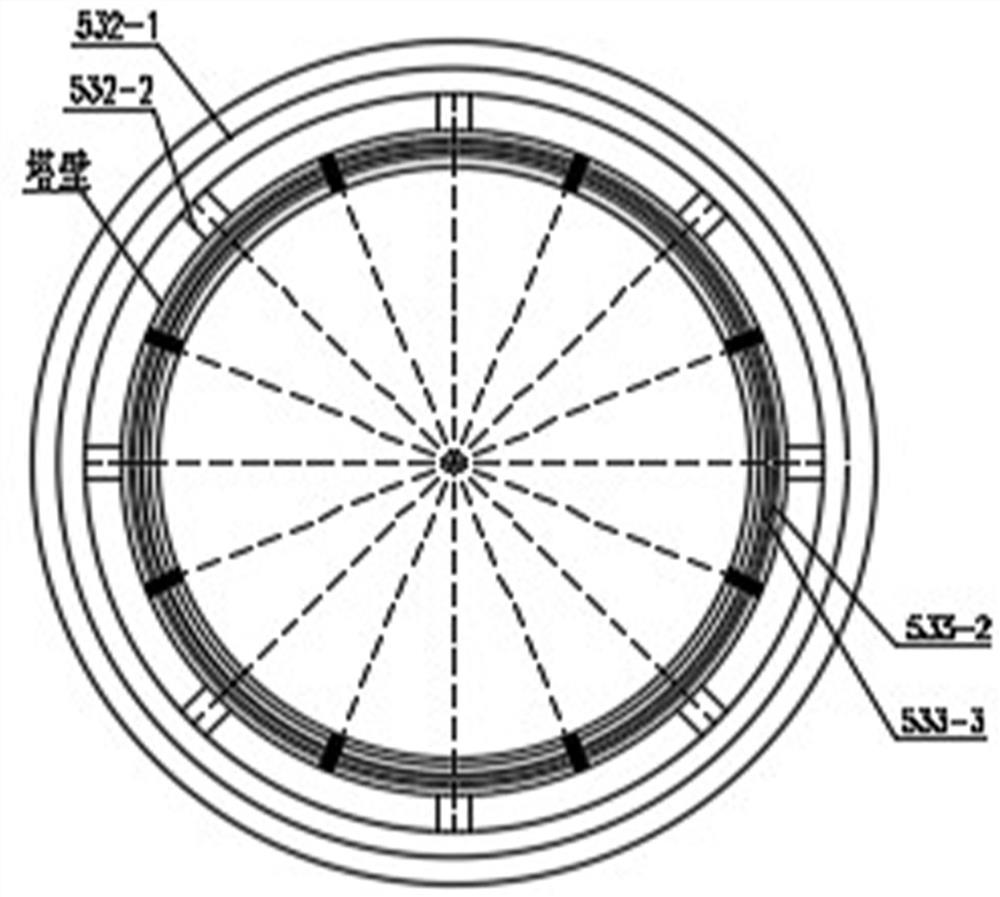

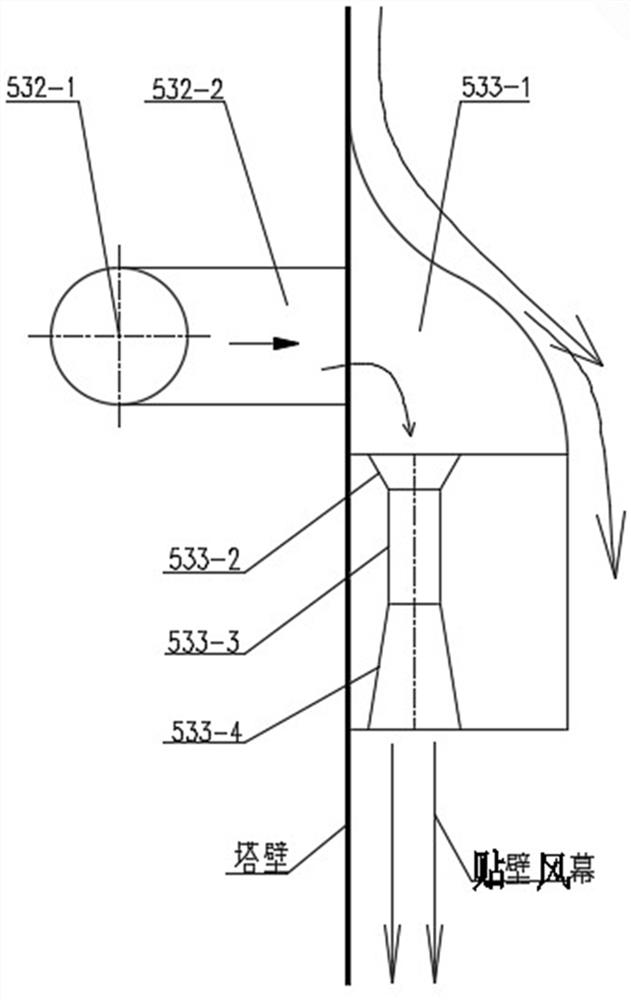

[0035] Please refer to figure 1 and figure 2 , the present invention proposes a system for removing heavy metals and chloride ions in the evaporation and crystallization process of desulfurization wastewater. The system includes an SCR reactor 1, an air preheater 2, a primary heat pipe evaporator 3, a secondary heat pipe evaporator 4, Hot air curtain drying tower 5, desulfurization waste water storage tank 6 and indirect evaporative cooler 13; said SCR reactor 1 is respectively connected with air preheater 2, primary heat pipe evaporator 3, secondary heat pipe evaporator 4, hot air through pipelines The curtain drying tower 5 is connected; the air preheater 2 is respectively connected with the primary heat pipe evaporator 3, the secondary heat pipe evaporator 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com