Foamed biodegradable resin and production process thereof

A biodegradable resin and production process technology, applied in the field of polymer materials, to achieve the effects of low apparent density, increased cell density, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

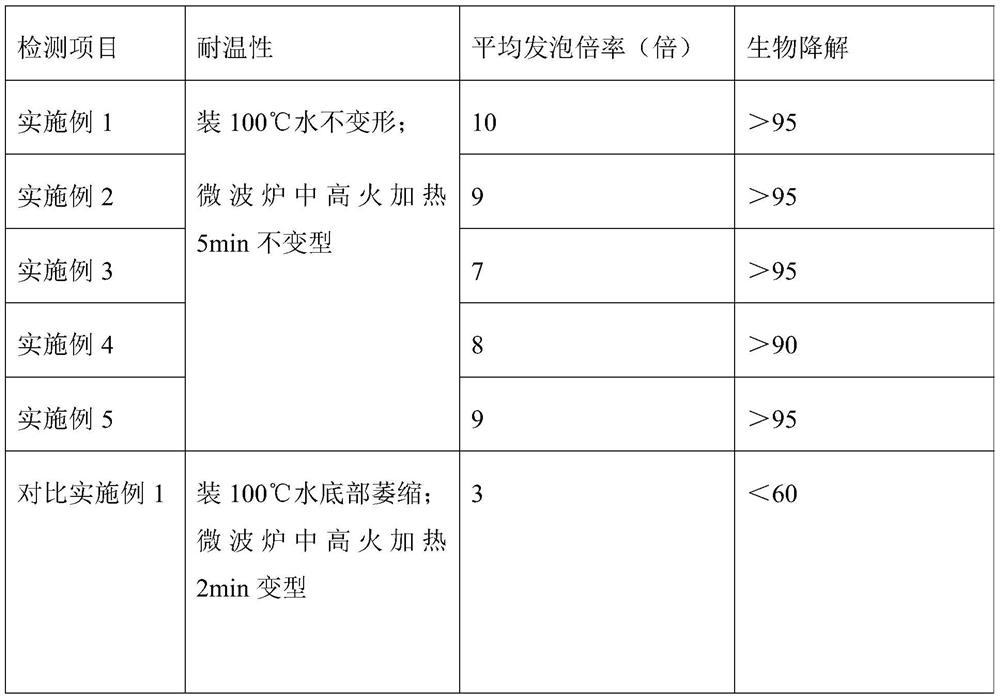

Examples

Embodiment 1

[0028] Dissolve 50 parts of PLA in dichloromethane, then add nitric acid solution dropwise and carry out oxidation pretreatment at no higher than 60°C, then adjust the pH of the solution to 6-8, then cool to room temperature, and evaporate the solvent to obtain modified PLA . The obtained modified PLA was mixed with 2 parts of epoxy-functionalized ADR chain extender and 14 parts of polycaprolactone, and then baked at 60 ° C for 10 h, then added 2 parts of polyethylene glycol and thermoplastic starch (density: 1.2 g / cm 3 , melt index: 1-3g / 10min (190°C / 2.16kg), volatile matter <0.3%) 20 parts are mixed uniformly by the mixer, then added to the twin-screw extruder, blended at high temperature and high shear After extruding the die, the strands are air-cooled and sent to a pelletizer to pelletize to obtain biodegradable resin masterbatches. The obtained biodegradable resin masterbatch and 9 parts of compound polymer masterbatch of azodicarbonamide and sodium bicarbonate are mi...

Embodiment 2

[0030] Dissolve 40 parts of PLA in dichloromethane, then add nitric acid solution dropwise and carry out oxidation pretreatment at no higher than 60°C, then adjust the pH of the solution to 6-8, then cool to room temperature, and evaporate the solvent to obtain modified PLA . The obtained modified PLA was mixed with 2 parts of epoxy-functionalized ADR chain extender and 18 parts of polycaprolactone, and then baked at 60°C for 10 h, and then 2 parts of trimethylolpropane and thermoplastic starch (density: 1.2 g / cm 3, melt index: 1-3g / 10min (190°C / 2.16kg), volatile matter <0.3%) 25 parts are mixed uniformly by the mixer, then added to the twin-screw extruder, blended at high temperature and high shear After extruding the die, the strands are air-cooled and sent to a pelletizer to pelletize to obtain biodegradable resin masterbatches. Mix the obtained biodegradable resin masterbatch and 10 parts of compound polymer masterbatch of modified sodium bicarbonate and citric acid in a...

Embodiment 3

[0032] Dissolve 50 parts of PLA in dichloromethane, then add nitric acid solution dropwise and carry out oxidation pretreatment at no higher than 60°C, then adjust the pH of the solution to 6-8, then cool to room temperature, and evaporate the solvent to obtain modified PLA . The obtained modified PLA was mixed with 3 parts of epoxy-functionalized ADR chain extender and 18 parts of polyglycolic acid, and then baked at 60°C for 10 hours, and then 3 parts of polyethylene glycol and thermoplastic starch (density: 1.2g / cm 3 , melt index: 1-3g / 10min (190℃ / 2.16kg), volatile matter <0.3%) 10 parts are mixed uniformly by the mixer, then added to the twin-screw extruder, blended at high temperature and high shear After extruding the die, the strands are air-cooled and sent to a pelletizer to pelletize to obtain biodegradable resin masterbatches. Mix the obtained biodegradable resin masterbatch and 12 parts of compound polymer masterbatch of modified sodium bicarbonate and citric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com