Polyacetal resin composition and method for producing same

A polyacetal resin and a technology for a production method, which are applied in the field of polyacetal resin compositions, can solve problems such as difficult formaldehyde formaldehyde, and achieve the effects of inhibiting mold scale, reducing the amount of formaldehyde generated, and having excellent friction and wear characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] In the preparation of the composition using an extruder, it is preferable to use an extruder having one or more devolatilization vents, and furthermore, to any position from the main feed port to the devolatilization vent, the relative 100 parts by mass of the polyacetal polymer is about 0.1 to 10 parts by mass of water and low-boiling point alcohols, and formaldehyde and the like generated during the extrusion process are preferably devolatilized and removed from the devolatilization exhaust port together with water and low-boiling point alcohols . Thereby, the amount of formaldehyde generated from the polyacetal resin composition and its molded article can be further reduced.

[0105] The polyacetal resin composition of the present invention thus prepared can be molded by conventionally known various molding methods such as injection molding, extrusion molding, compression molding, vacuum molding, blow molding, and foam molding.

[0106] The present invention also in...

Embodiment

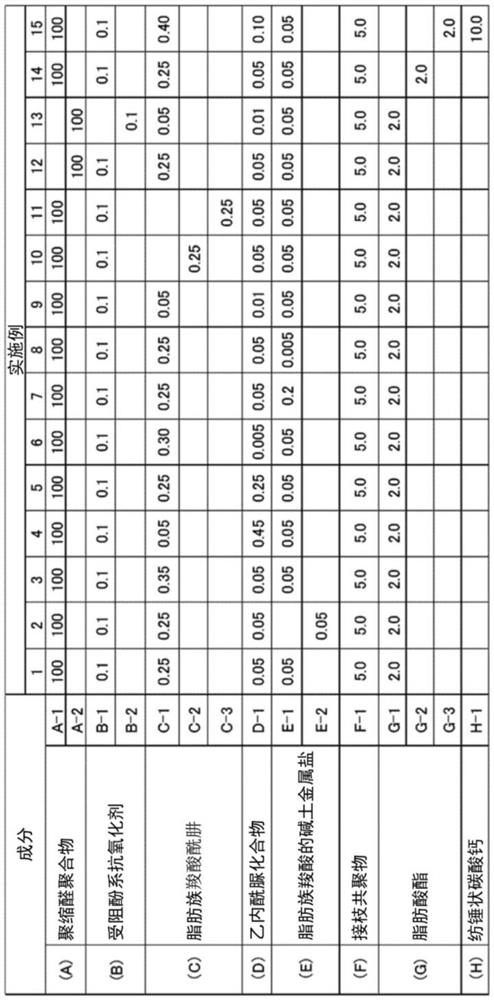

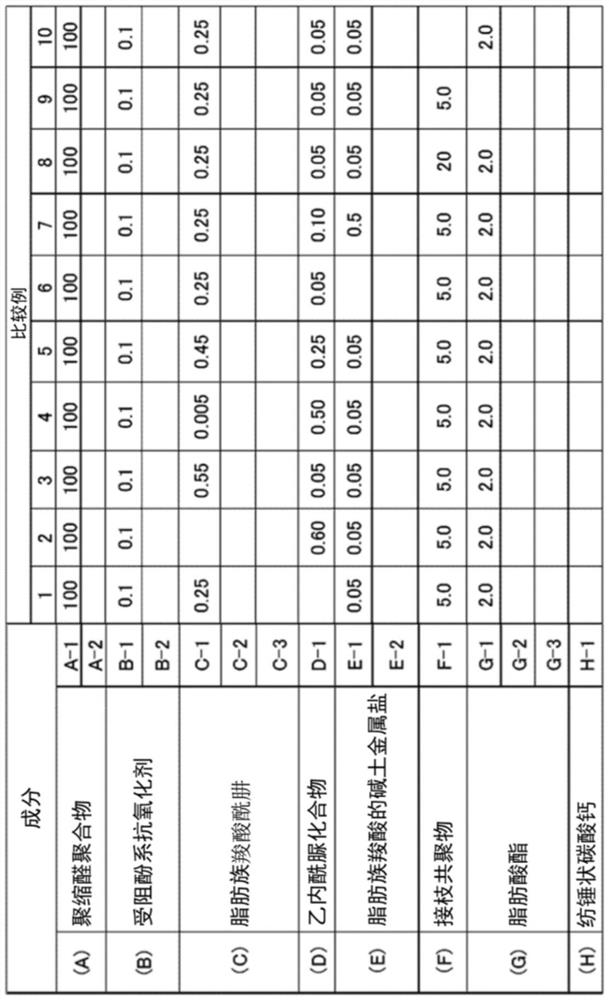

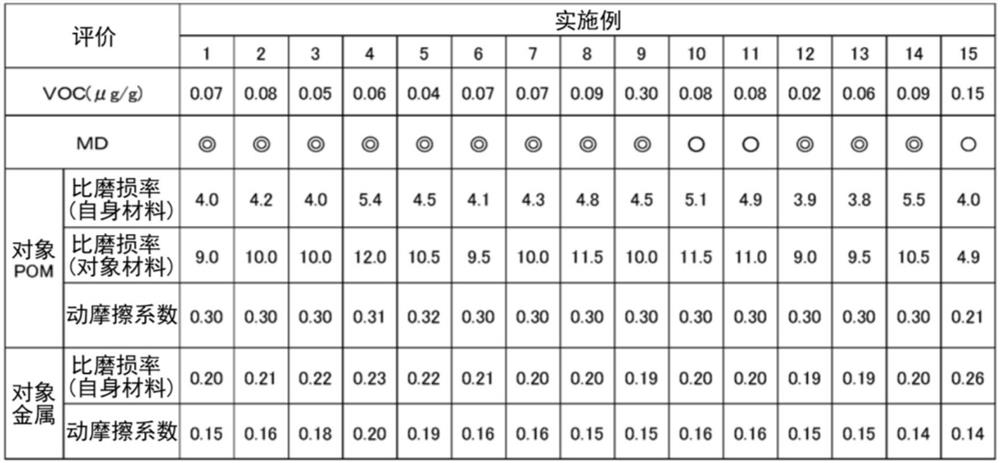

[0109] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these. In addition, "part" in an Example and a comparative example means a mass part. In addition, each property evaluated in the Example and the comparative example and its evaluation method are as follows. The units of the numerical values described in Tables 1 and 2 are parts by mass.

[0110] The various components shown in Tables 1 and 2 were added and mixed at the ratios shown in Tables 1 and 2, and melt-kneaded in a vented twin-screw extruder to prepare a pellet-like composition.

[0111] The components described in Tables 1 and 2 used in Examples are the following components.

[0112] ·(A) Polyacetal polymer

[0113] A-1: Using a twin-shaft paddle-type continuous polymerizer, continuously supply 1,3-dioxolane to all monomers (trioxane and 1,3-dioxolane) 3.3% by mass, trioxane of 1000ppm methylal, while supplying boron trifluoride dibutyl etherate to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com