Preparation method of biomass-based low-odor printing ink

A low-odor, biomass-based technology, applied in the field of printing materials, can solve problems such as adverse health effects of printing operators, pollution of packaging products, and consumer hazards, to avoid potential risks of poisoning, fast curing speed, and good adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of a biomass-based low-odor ink of the present invention comprises the following raw materials in parts by weight: 40-60 parts of itaconic acid abietic acid modified epoxy soybean oil, 10-25 parts of vegetable oil, 5-15 parts of pigments, fillers 2-10 parts, 1-3 parts of adhesion promoter, 0.5-2 parts of anti-skinning agent, 1-3 parts of drier, 2-6 parts of leveling agent, 2-5 parts of dispersant and 0.1 parts of defoamer -1 part, the sum of the mass of the above components is 100%;

[0023] Specifically include the following steps:

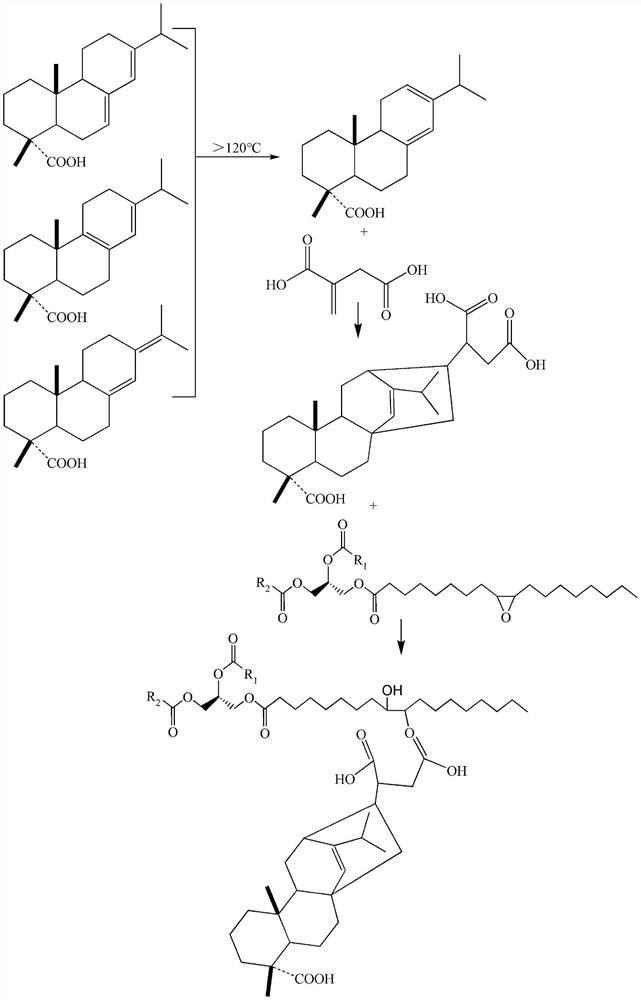

[0024] Step 1, adopting itaconic abietic acid modified epoxy soybean oil;

[0025] Step 1.1, under nitrogen atmosphere, add rosin, itaconic acid, polymerization inhibitor and toluene into the reaction kettle, heat at 120°C until the rosin melts, then raise the temperature to 130-140°C, react for 3-5h, remove Toluene, obtain itaconic acid modified rosin;

[0026] In step 1.1, the mass ratio of rosin and itaconic ac...

Embodiment 1

[0042] A preparation method of biomass-based low-odor ink, specifically comprising the steps of:

[0043] Step 1, preparation of itaconic acid abietic acid modified epoxy soybean oil:

[0044] Take 20g of rosin, 40g of itaconic acid, 0.4g of hydroquinone, and 20mL of toluene into the reaction kettle. After bubbling nitrogen for 30 minutes, heat to 120°C. After the rosin melts, continue to heat to 140°C. Toluene is removed by steaming to obtain itaconic acid modified rosin;

[0045] Take 28.5g of itaconic acid modified rosin, 30g of epoxidized soybean oil, 0.3g of triphenylphosphine and 0.3g of hydroquinone into the reaction kettle, bubble nitrogen for 30min, heat to 110°C, and react for 4h to obtain clothing Conic acid rosin modified epoxy soybean oil.

[0046]Step 2, add 60 parts of itaconic acid rosin modified epoxy soybean oil, 7.5 parts of tung oil, 2.5 parts of refined soybean oil, 2 parts of polyether modified organosiloxane, 2 parts of oleic acid, 1 part of acrylate ...

Embodiment 2

[0048] A preparation method of biomass-based low-odor ink, specifically comprising the steps of:

[0049] Step 1, preparation of itaconic acid abietic acid modified epoxy soybean oil:

[0050] Take 20g of rosin, 60g of itaconic acid, 0.3g of hydroquinone, and 30mL of toluene into the reaction kettle. After bubbling nitrogen for 30 minutes, heat to 120°C. After the rosin is melted, continue to heat to 130°C. Toluene is removed by steaming to obtain itaconic acid modified rosin;

[0051] Take 40.5g of itaconic acid modified rosin, 30g of epoxidized soybean oil, 1.5g of N,N-dimethylbenzylamine and 0.15g of hydroquinone into the reaction kettle, bubble nitrogen for 30min, and heat to 105°C. After reacting for 6 hours, itaconic acid rosin-modified epoxy soybean oil was obtained.

[0052] Step 2, add 40 parts of itaconic acid rosin modified epoxy soybean oil, 6.25 parts of tung oil, 18.75 parts of refined soybean oil, 6 parts of polyether modified organosiloxane, 5 parts of oleic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com