Water-based chemical-medium-resistant weather-resistant visible-light near-infrared camouflage coating and preparation method thereof

A technology of chemical resistance and weather resistance, which is applied in the field of visible light and near-infrared camouflage coatings and its preparation, can solve the problems of severe corrosion, reduced camouflage performance, loss of strength, etc., and achieve the effect of convenient painting and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

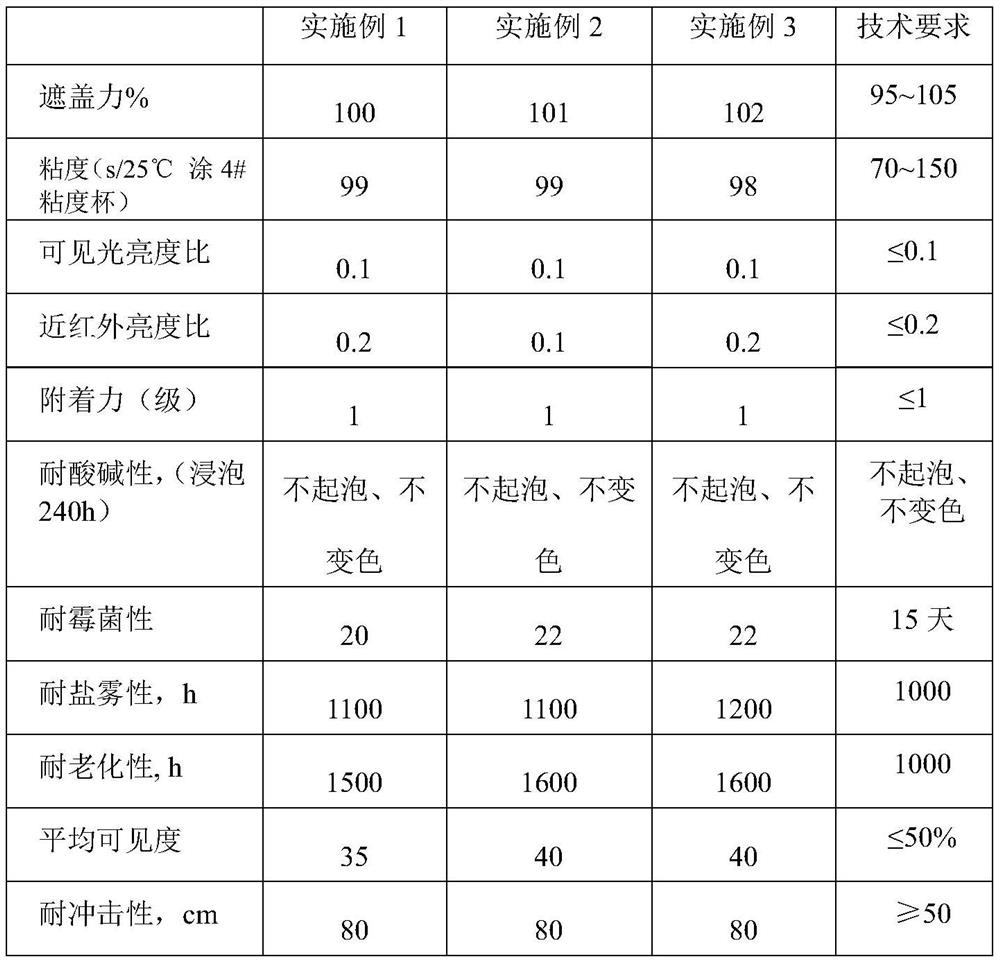

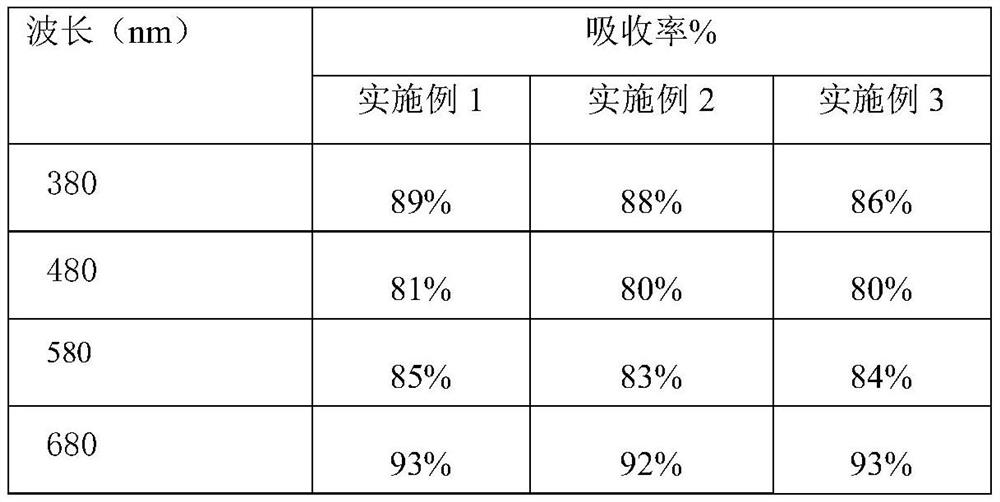

Examples

Embodiment 1

[0024] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0025] (1) Add water-based acrylic resin, water-based epoxy resin, JX-628 blocked water-based polyisocyanate curing agent, dispersant, defoamer, leveling agent, and 2 / 3 of water into the container, and use a high-speed disperser at 500rpm Disperse at a speed of 10 minutes, maintain the speed, slowly add pigments, metal fillers, potassium titanate whiskers, and the remaining water, increase the speed to 1800 rpm, and disperse for 30 minutes;

[0026] (2) Grind the dispersed materials with a horizontal sand mill, the material of the grinding medium is zirconium beads, the diameter of the zirconium beads is 0.8-1.0 mm, until the fineness of the coating is ground to ≤20 μm;

[0027] (3) Use a high-speed disperser to disperse the functional filler into the ground material at a speed of 500 rpm, increase the speed to 1500 rpm, and disperse for 10 minutes to obtain the product.

Embodiment 2

[0029] (1) Add water-based acrylic resin, water-based epoxy resin, JX-628 blocked water-based polyisocyanate curing agent, dispersant, defoamer, leveling agent, and 2 / 3 of water into the container, and use a high-speed disperser at 500rpm Disperse at a speed of 10 minutes, maintain the speed, slowly add pigments, metal fillers, potassium titanate whiskers, and the remaining water, increase the speed to 1800 rpm, and disperse for 30 minutes;

[0030] (2) Grind the dispersed materials with a horizontal sand mill, the material of the grinding medium is zirconium beads, the diameter of the zirconium beads is 0.8-1.0 mm, until the fineness of the coating is ground to ≤20 μm;

[0031] (3) Use a high-speed disperser to disperse the functional filler into the ground material at a speed of 500 rpm, increase the speed to 1500 rpm, and disperse for 10 minutes to obtain the product.

Embodiment 3

[0033] (1) Add water-based acrylic resin, water-based epoxy resin, JX-628 blocked water-based polyisocyanate curing agent, dispersant, defoamer, leveling agent, and 2 / 3 of water into the container, and use a high-speed disperser at 400rpm Disperse at a speed of 20 minutes, maintain the speed, slowly add pigments, metal fillers, potassium titanate whiskers, and the remaining water, increase the speed to 1600 rpm, and disperse for 40 minutes;

[0034] (2) Grind the dispersed materials with a horizontal sand mill, the material of the grinding medium is zirconium beads, the diameter of the zirconium beads is 0.8-1.0 mm, until the fineness of the coating is ground to ≤20 μm;

[0035] (3) Use a high-speed disperser to disperse the functional filler into the ground material at a speed of 400 rpm, increase the speed to 1400 rpm, and disperse for 20 minutes to obtain the product.

[0036] Table 1

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com