A kind of organic high temperature resistant encapsulant and preparation method thereof

A technology of high temperature resistance and encapsulation adhesive, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of easy cracking, poor stability, and difficulty in meeting the requirements of encapsulation, and achieve improved adhesion Excellent bonding strength, easy industrial production, and improved packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

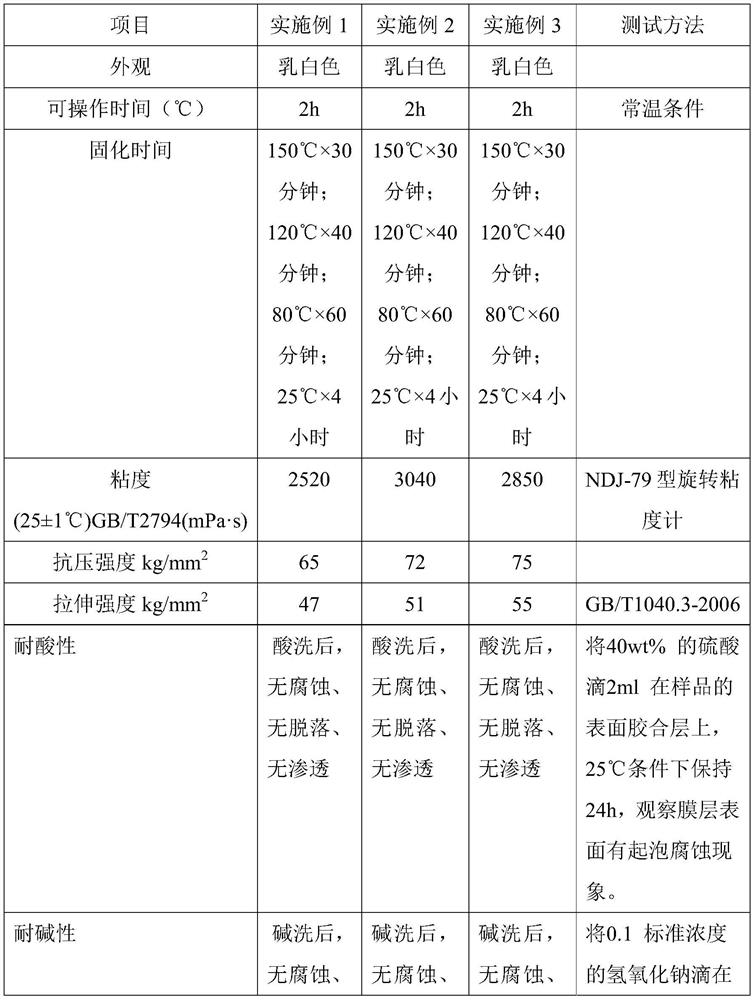

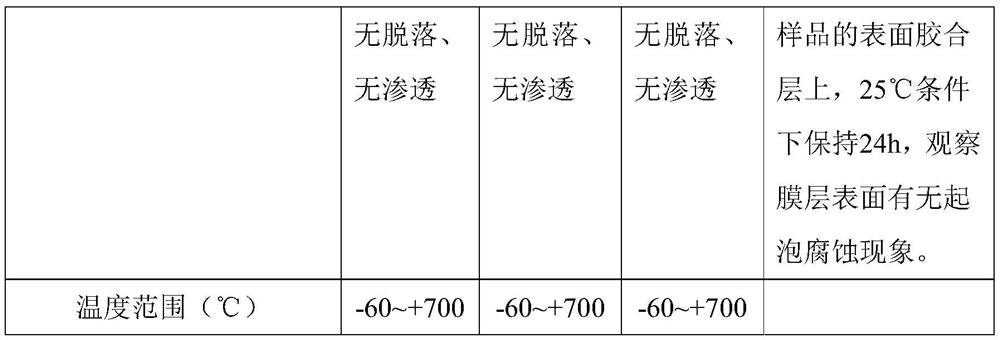

Embodiment 1

[0027] (1), the attapulgite clay powder is modified and mixed with the nano-zirconia powder in a mass ratio of 100:15 to prepare a composite powder;

[0028] (2), take 5 parts of silane coupling agent by weight and put it in the beaker, pour 9 parts of absolute ethanol into the stirrer, then add 3 parts of formic acid as a catalyst, adjust the pH value to 9, and use an electric mixer Stir for 3 hours at a stirring speed of 350 r / min. After the phases are uniformly mixed, seal the solution, oscillate in an ultrasonic cleaning agent for 3 hours, and finally place it in a 50°C water bath to react to a gel, and add it to the gel. 40 parts of tetrahydrofuran (THF) was dissolved, added 20 parts of modified silicone resin, put into a magnetic stirrer and stirred at a speed of 200r / min for 1-3h, set aside;

[0029] (3), put 7.5 parts of the composite powder prepared in step (1) into the mixing system of step (2), add 5 parts of active agent, fully stir with a cross-blade stirrer, and ...

Embodiment 2

[0032] (1), the attapulgite clay powder is modified and mixed with the nano-zirconia powder in a mass ratio of 100:20 to prepare a composite powder;

[0033] (2), take 8 parts of silane coupling agent by weight and put it in the beaker, pour 10 parts of absolute ethanol into the stirrer, then add 2 parts of formic acid as a catalyst, adjust the pH value to 9, and use an electric mixer Stir for 4 hours at a stirring speed of 400 r / min. After the phases are uniformly mixed, the solution is sealed, ultrasonically shaken in an ultrasonic cleaning agent for 1 hour, and finally placed in a 50 °C water bath to react to a gel, and added to the gel. 40 parts of tetrahydrofuran (THF) was dissolved, added 20 parts of modified silicone resin, put into a magnetic stirrer and stirred at a speed of 250r / min for 1h, set aside for use;

[0034] (3), put 5 parts of the composite powder prepared in step (1) into the mixing system of step (2), add 2 parts of active agent, fully stir with a cross ...

Embodiment 3

[0037] (1), the attapulgite clay powder is modified and mixed with the nano-zirconia powder in a mass ratio of 100:20 to prepare a composite powder;

[0038] (2), take 6 parts of silane coupling agent by weight and put it in the beaker, pour 8 parts of absolute ethanol into the stirrer, add 2 parts of formic acid as a catalyst, adjust the pH value to 9, and use electric The mixer was stirred for 4 hours, and the stirring speed was 350 r / min. After the phases were uniformly mixed, the solution was sealed, and ultrasonically oscillated in an ultrasonic cleaning agent for 1 hour. Finally, it was placed in a 50 °C water bath to react to a gel. Add 45 parts of tetrahydrofuran (THF) to dissolve it, add 20 parts of modified silicone resin, put it into a magnetic stirrer and stir at a speed of 250r / min for 1h, set aside;

[0039] (3), put 5 parts of the composite powder prepared in step (1) into the mixing system of step (2), add 2 parts of active agent, fully stir with a cross-blade ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com