Preparation method of anesthetic

A technology of anesthetics and batching tanks, applied in the field of anesthetics, can solve the problems of poor nitrogen protection effect, easy nitrogen floating, and low efficiency, and achieve the effect of enhancing nitrogen protection effect and accelerating cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

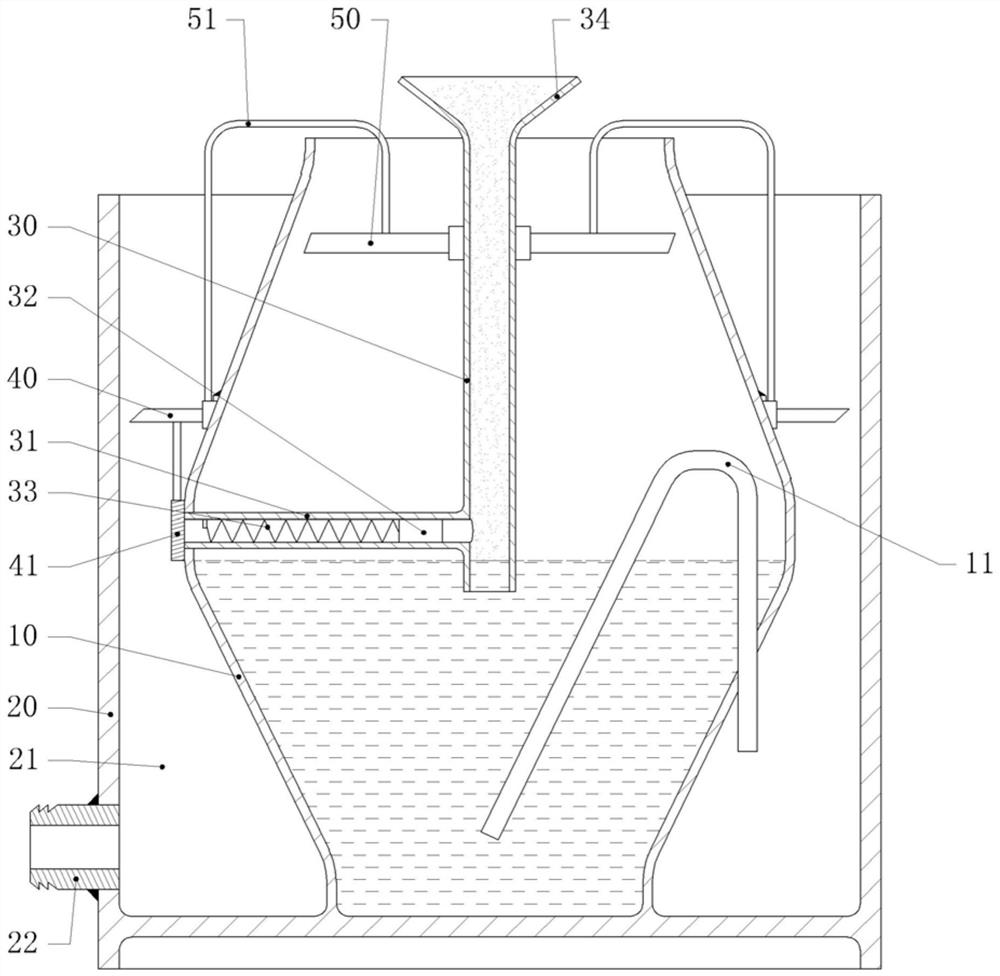

[0037] The reference signs in the accompanying drawings of the description include: batching tank 10, air intake pipe 11, air guiding cylinder 21, liquid nitrogen inlet 22, material guide pipe 30, regulating pipe 31, plunger 32, compression spring 33, feed hopper 34, turbine 40, arc baffle plate 41, air guide fan 50, spoke 51.

[0038] The preparation method of the anesthetic is completed using the anesthetic preparation device disclosed in this embodiment, as shown in the attached figure 1 As shown, the main body of the anesthetic agent preparation device is a batching tank 10, and the outer periphery of the batching tank 10 is provided with an air guiding cylinder 21, and an air guiding channel is formed between the batching tank 10 and the air guiding tube 21; The diameter of the middle part is larger than that of both ends, and the air guiding cylinder 21 is cylindrical, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com