Method for rapidly preparing underwater super-oleophobic anticorrosive coating

An underwater super oleophobic and anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor chemical stability, poor salt resistance, complicated preparation process, etc., to improve mechanical stability , solve the effect of long preparation time and reduce capillary action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for rapidly preparing an underwater super-oleophobic anti-corrosion coating, weighing 7g of F51 epoxy resin and 1g of cardanol-modified amine epoxy curing agent, and ultrasonically mixing and stirring the two in 100g of ethyl acetate The mixed solution of epoxy resin and curing agent is sprayed on the glass sheet with a spray gun, and it is pre-cured at 80 ℃ for 3 minutes at once, and then the hydrophilic nano particle silicon dioxide dispersion liquid of 1g is sprayed on the epoxy resin coating with a spray gun. Finally, put the entire coating in an oven at 80 °C for 10 minutes to cure and take it out to obtain an underwater super-oleophobic coating.

Embodiment 2

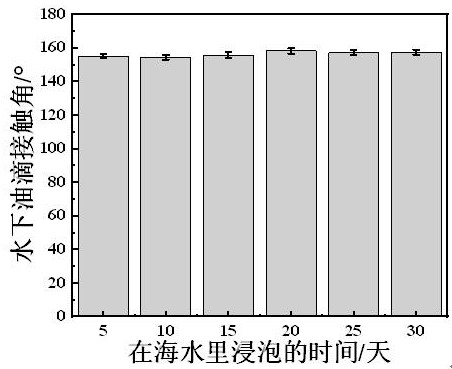

[0019] A method for rapidly preparing an underwater super-oleophobic anti-corrosion coating, weighing 8g of F51 epoxy resin and 2g of cardanol-modified amine epoxy curing agent, and ultrasonically mixing and stirring the two in 120g of ethyl acetate ; Spray the mixed solution of epoxy resin and curing agent on the glass sheet with a spray gun, immediately precure it at 80 ℃ for 3 minutes, then spray the hydrophilic nano particle silicon dioxide dispersion of 1.5g on the epoxy resin with a spray gun Finally, put the entire coating in an oven at 80°C for 10 minutes to cure and take it out to obtain an underwater super-oleophobic coating. The contact angle of the underwater oil droplet is as follows figure 1 shown.

Embodiment 3

[0021] A method for rapidly preparing an underwater super-oleophobic anti-corrosion coating, weighing 10g of F51 epoxy resin and 3g of cardanol-modified amine epoxy curing agent, and ultrasonically mixing and stirring the two in 150g of ethyl acetate ; The mixed solution of epoxy resin and curing agent is sprayed on the glass sheet with a spray gun, and it is pre-cured at 80 ℃ for 4 minutes at once, and then the hydrophilic nano particle silicon dioxide dispersion of 2g is sprayed on the epoxy resin coating with a spray gun Finally, put the entire coating in an oven at 80 °C for 10 minutes to cure and take it out to obtain an underwater super-oleophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com