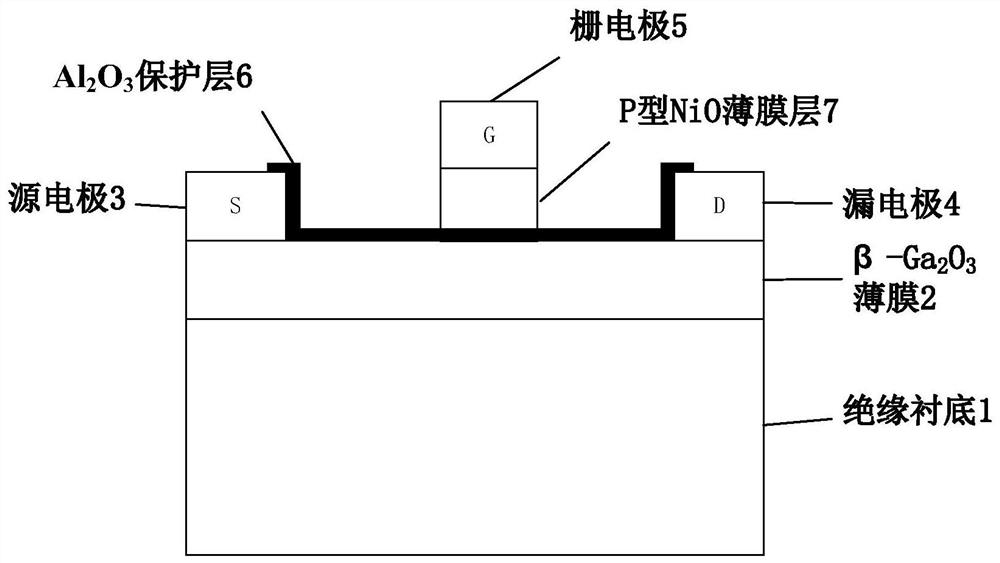

PN junction gate-controlled gallium oxide field effect transistor and preparation method thereof

A gallium oxide field and transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the constraints on the development and application of gallium oxide-based devices, the easy passivation activation rate of acceptor impurity ions, and the lack of shallow energy Eliminate the self-heating effect, high lattice integrity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

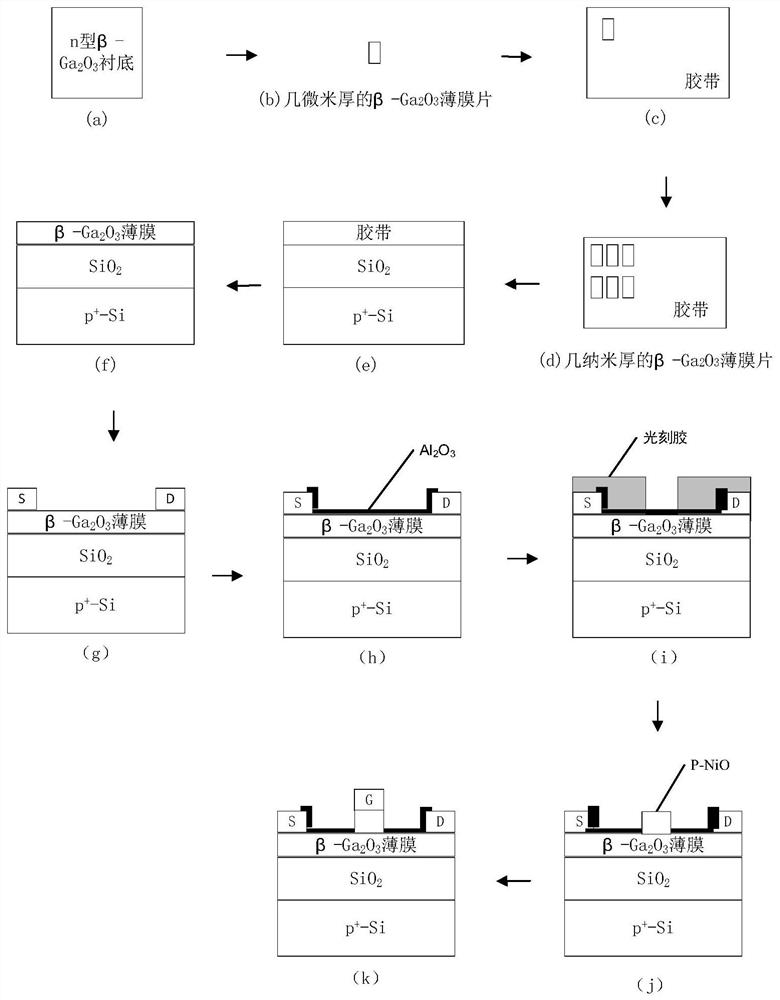

[0032] Embodiment 1, making insulating substrate is SiO 2 / p + -Si, n-type β-Ga 2 o 3 Gallium oxide field effect transistor with film thickness of 100nm and p-type NiO film thickness of 200nm.

[0033] Step 1: Cleaning β-Ga 2 o 3 single crystal substrates, such as figure 2 (a).

[0034] Select the doping concentration as 2.7e18cm -3 n-type β-Ga 2 o 3 The single crystal substrate was then ultrasonically cleaned in acetone solution, absolute ethanol, and deionized water for 5 min each, and then dried with nitrogen.

[0035] Step 2: Prepare β-Ga with a thickness of micrometers by mechanical exfoliation 2 o 3 film.

[0036] Due to β-Ga 2 o 3 The bonding force between the crystal (100) planes is weak, so the mechanical exfoliation method is used, and the n-type β-Ga after cleaning 2 o 3 Cleave the crystal along the (100) plane with a blade or tweezers on the single crystal substrate to obtain micron-sized β-Ga 2 o 3 film, such as figure 2 (b);

[0037] The pre...

Embodiment 2

[0055] Embodiment 2, making the insulating substrate is sapphire, n-type β-Ga with a thickness of 300nm 2 o 3 Gallium oxide field effect transistor with film thickness of 100nm and p-type NiO film thickness of 300nm.

[0056] Step 1: Cleaning β-Ga 2 o 3 single crystal substrates, such as figure 2 (a).

[0057] 1.1) Select the doping concentration to be 3e18cm -3 n-type β-Ga 2 o 3 single crystal substrate;

[0058] 1.2) The selected n-type β-Ga 2 o 3 The single crystal substrate was ultrasonically cleaned in acetone solution, absolute ethanol, and deionized water for 5 min each, and then dried with nitrogen.

[0059] Step 2: Prepare β-Ga with a thickness of micron order by mechanical exfoliation 2 o 3 film.

[0060] 2.1) According to β-Ga 2 o 3 The crystal (100) has a weak interplanetary bonding force, and the mechanical exfoliation method is used to clean the n-type β-Ga 2 o 3 Cleave the crystal along the (100) plane with a blade or tweezers on the single cryst...

Embodiment 3

[0083] Embodiment 3, making the insulating substrate is sapphire, n-type β-Ga with a thickness of 200nm 2 o 3 Gallium oxide field effect transistor with film thickness of 75nm and p-type NiO film thickness of 150nm.

[0084] Step A: Cleaning β-Ga 2 o 3 single crystal substrates, such as figure 2 (a).

[0085] First, choose a doping concentration of 1e18cm -3 n-type β-Ga 2 o 3 single crystal substrate;

[0086] Then, the selected n-type β-Ga 2 o 3 The single crystal substrate was ultrasonically cleaned in acetone solution, absolute ethanol, and deionized water for 5 min each, and then dried with nitrogen.

[0087] Step B: Prepare micron-scale β-Ga by mechanical exfoliation 2 o 3 film.

[0088] First, using the mechanical stripping method, the cleaned n-type β-Ga 2 o 3 Cleave the crystal along the (100) plane with a blade or tweezers on the single crystal substrate to obtain micron-sized β-Ga 2 o 3 film, such as figure 2 (b);

[0089] Then, the prepared micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| etching power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com